Acidic high heavy metal ions-containing mine waste water high-efficiency cycling treatment system

A technology for heavy metal ions and mine wastewater, which is applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve problems such as poor recycling and utilization of heavy metals, gravel, and sludge, and inconvenient cleaning of grilles , to achieve the effect of resource recovery and effective utilization, improve sedimentation filtration efficiency, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

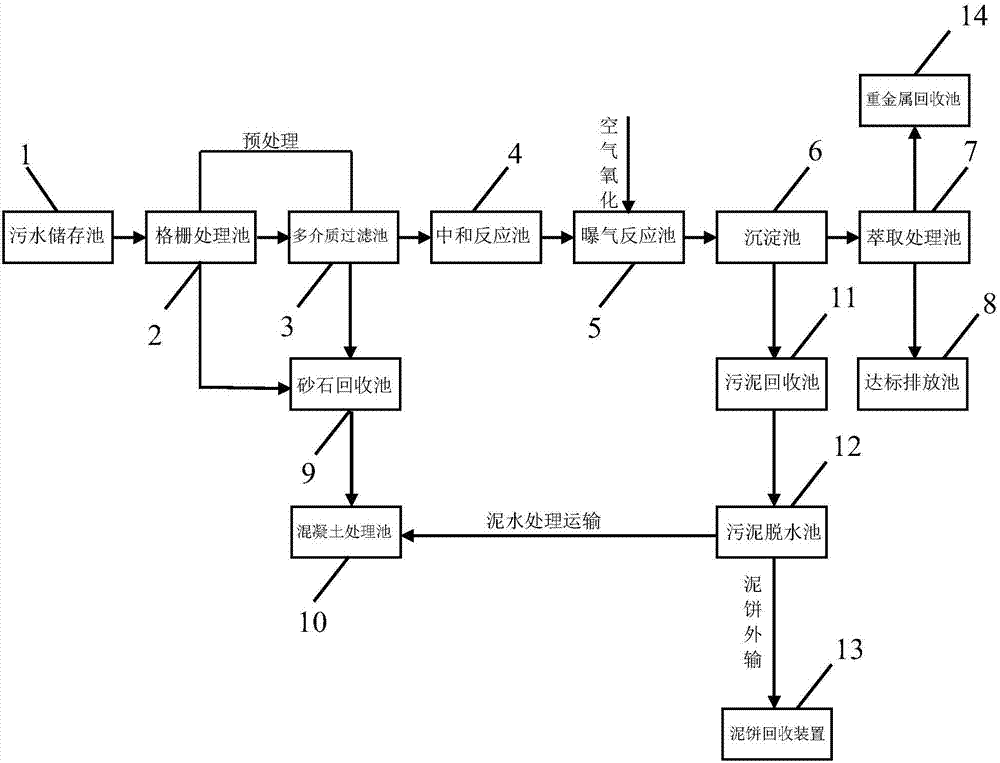

[0024] Such as figure 1 As shown, this embodiment provides a high-efficiency circulation treatment system for acidic mine wastewater containing heavy metal ions, including a sewage storage tank 1, a grid treatment tank 2, a multimedia filter tank 3, a neutralization reaction tank 4, and an exposure tank connected in sequence. Gas reaction tank 5, sedimentation tank 6, extraction treatment tank 7, standard discharge tank 8, a sandstone discharge port 15 is arranged at the bottom of the multimedia filter tank 3, and the sandstone discharge port 15 is connected to sandstone recovery through pipelines in sequence pool 9 and concrete treatment tank 10, the bottom of the settling tank 6 is provided with a sludge outlet, and the sludge outlet is connected to the sludge recovery tank 11, the sludge dewatering tank 12 and the mud cake recovery device 13 successively through pipelines, and the sludge The dewatering tank 12 is connected with the concrete treatment tank 10 through pipelin...

Embodiment 2

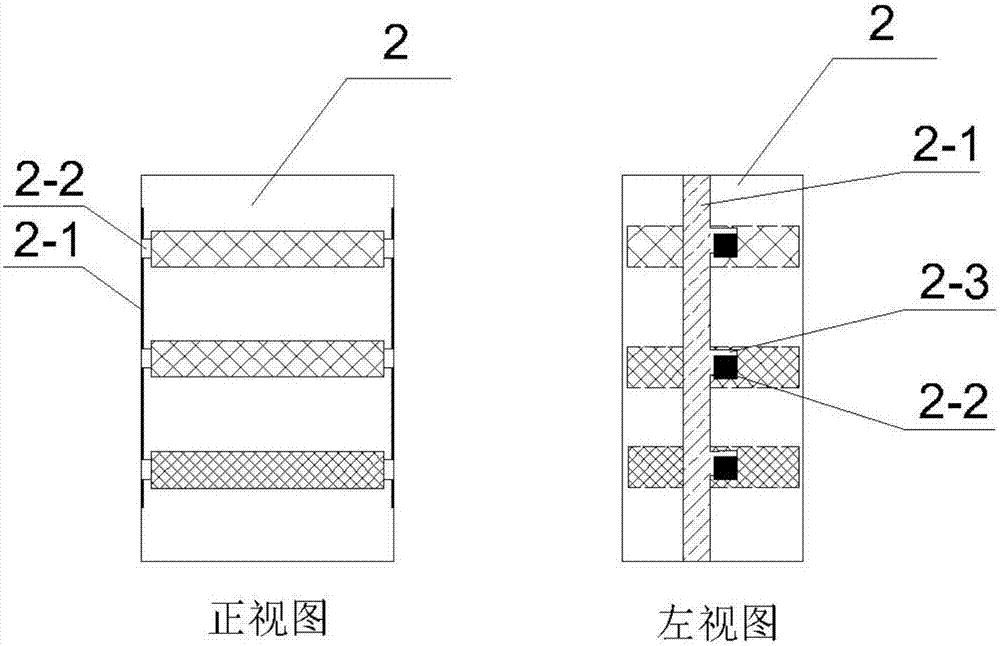

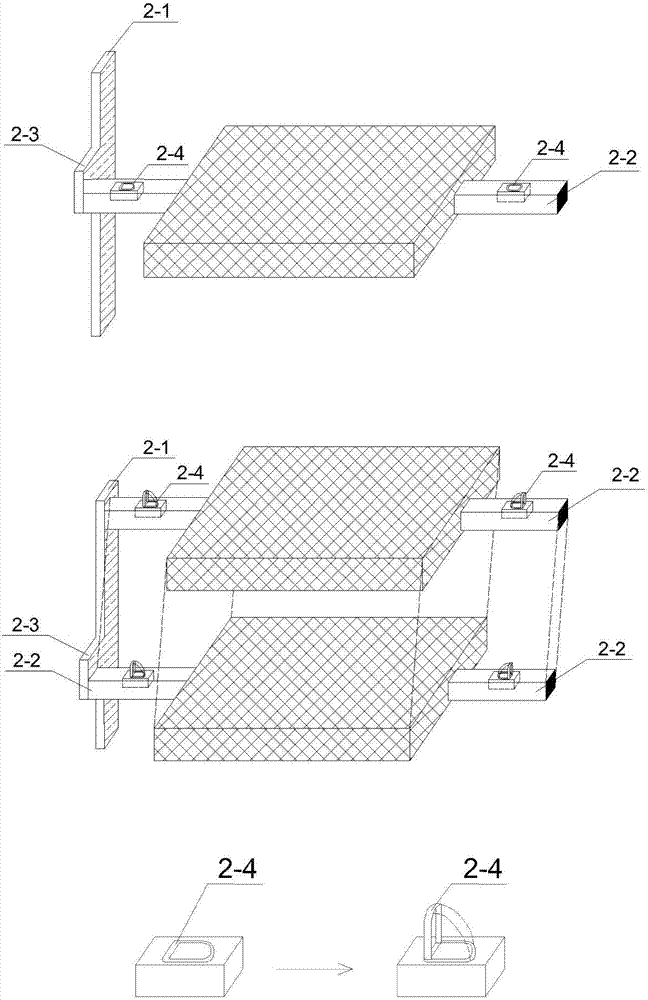

[0027] Such as figure 2 and 3 As shown, this embodiment provides a high-efficiency circulation treatment system for acidic mine wastewater containing heavy metal ions, including a sewage storage tank 1, a grid treatment tank 2, a multimedia filter tank 3, a neutralization reaction tank 4, and an exposure tank connected in sequence. Gas reaction tank 5, sedimentation tank 6, extraction treatment tank 7, standard discharge tank 8, a sandstone discharge port 15 is arranged at the bottom of the multimedia filter tank 3, and the sandstone discharge port 15 is connected to sandstone recovery through pipelines in sequence pool 9 and concrete treatment tank 10, the bottom of the settling tank 6 is provided with a sludge outlet, and the sludge outlet is connected to the sludge recovery tank 11, the sludge dewatering tank 12 and the mud cake recovery device 13 successively through pipelines, and the sludge The dewatering tank 12 is connected with the concrete treatment tank 10 through...

Embodiment 3

[0033] Such as Figure 1-4 As shown, this embodiment provides a high-efficiency circulation treatment system for acidic mine wastewater containing heavy metal ions, including a sewage storage tank 1, a grid treatment tank 2, a multimedia filter tank 3, a neutralization reaction tank 4, and an exposure tank connected in sequence. Gas reaction tank 5, sedimentation tank 6, extraction treatment tank 7, standard discharge tank 8, a sandstone discharge port 15 is arranged at the bottom of the multimedia filter tank 3, and the sandstone discharge port 15 is connected to sandstone recovery through pipelines in sequence pool 9 and concrete treatment tank 10, the bottom of the settling tank 6 is provided with a sludge outlet, and the sludge outlet is connected to the sludge recovery tank 11, the sludge dewatering tank 12 and the mud cake recovery device 13 successively through pipelines, and the sludge The dewatering tank 12 is connected with the concrete treatment tank 10 through pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com