Method for preparing scandium oxide via chlorinated soot

A technology of chlorinated fume and scandium oxide, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of low purity, low scandium recovery rate, low extraction rate, etc. problems, to achieve the effect of increasing market competitiveness, industrialization of high-purity production process, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

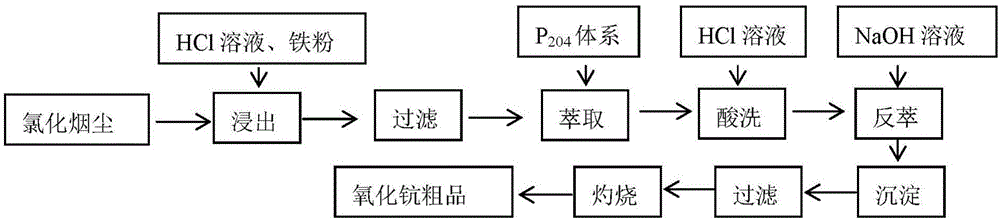

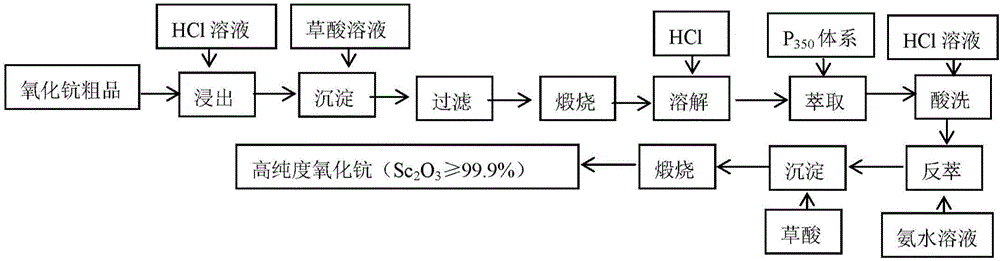

[0037] Step A: add hydrochloric acid solution and excess iron powder to the raw material of chlorination fume and leach for 1.5 hours, the mass ratio of chlorination fume, dilute hydrochloric acid and iron powder is 5:9:0.1, press filter to obtain filtrate;

[0038] Step B: Add the filtrate obtained in step A to an appropriate amount of P with a ratio of O / A=1 / 1.5 204 system extractant for extraction, static phase separation, and enriched Sc 3+ of the extract;

[0039] Step C: using hydrochloric acid solution to wash the extract obtained in step B, to the Sc-enriched 3+ Adding a sodium hydroxide solution with a concentration of 1 mol / L to the organic phase solution, carrying out stripping at 65°C to obtain a precipitate, filtering, drying, and calcining at a high temperature to obtain the crude scandium oxide of the first enrichment;

[0040] Step D: adding the crude product of scandium oxide in step C to a hydrochloric acid solution for dissolving, removing the filter resid...

Embodiment 2

[0044] Step A: add hydrochloric acid solution and excess iron powder to the raw material of chlorination fume and leach for 1 hour, the mass ratio of chlorination fume, dilute hydrochloric acid and iron powder is 5:12:0.2, press filter to obtain filtrate;

[0045] Step B: Add the filtrate obtained in step A to an appropriate amount of P that is O / A=1 / 2.5 204 system extractant for extraction, static phase separation, and enriched Sc 3+ of the extract;

[0046] Step C: using hydrochloric acid solution to wash the extract obtained in step B, to the Sc-enriched 3+ Adding a sodium hydroxide solution with a concentration of 2 mol / L to the organic phase solution, carrying out stripping at 85°C to obtain a precipitate, filtering, drying, and calcining at a high temperature to obtain the crude scandium oxide of the first enrichment;

[0047] Step D: adding the crude product of scandium oxide in step C to a hydrochloric acid solution for dissolving, removing the filter residue by suct...

Embodiment 3

[0051] Step A: add hydrochloric acid solution and excess iron powder to the raw material of chlorination fume and leach for 2 hours, the mass ratio of chlorination fume, dilute hydrochloric acid and iron powder is 5:10:0.15, press filter to obtain filtrate;

[0052] Step B: Add the filtrate obtained in step A to an appropriate amount of P with a ratio of O / A=1 / 3.5 204 system extractant for extraction, static phase separation, and enriched Sc 3+ of the extract;

[0053] Step C: using hydrochloric acid solution to wash the extract obtained in step B, to the Sc-enriched 3+ Adding a sodium hydroxide solution with a concentration of 2 mol / L to the organic phase solution, carrying out stripping at 85°C to obtain a precipitate, filtering, drying, and calcining at a high temperature to obtain the crude scandium oxide of the first enrichment;

[0054] Step D: adding the crude product of scandium oxide in step C to a hydrochloric acid solution for dissolving, removing the filter resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com