Technology for removing nitrate nitrogen and phosphorus from water and synchronously recovering nutrient salts

A technology for nitrate nitrogen and nutrient salts, applied in the direction of phosphorus compounds, water pollutants, water/sewage treatment, etc., can solve the problems of increased cost and operational difficulty, and achieve good oxidation removal ability, convenient operation, and good removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

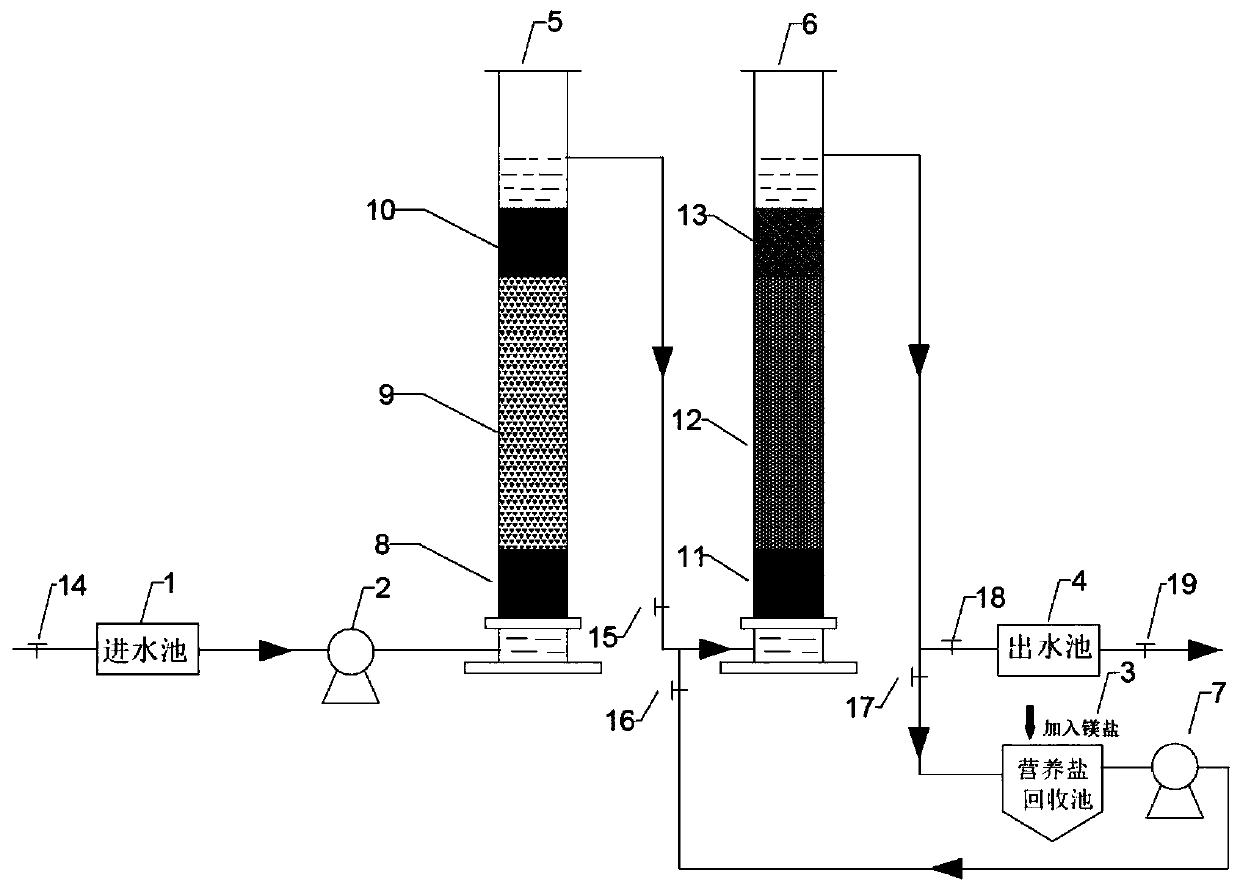

[0026] like figure 1 As shown, the present invention relates to a two-stage series-connected packed percolation bed system, including a water inlet tank, a nitrate nitrogen conversion bed, a nitrogen and phosphorus adsorption enrichment bed, a water outlet tank, a regeneration and nutrient salt recovery system, and a water distribution system to guide water into the percolation bed .

[0027] The water distribution system includes an inlet pool 1, metering pumps 2 and 7, an outlet pool 4, and interconnected water pipes.

[0028] The nitrate-nitrogen conversion bed 5, which is mainly used for nitrate conversion and organic matter removal, is arranged from bottom to top in order of 8 cm pebble support layer 8, iron-carbon micro-electrolysis layer 9 with a height of 45 cm, and the upper layer is a gravel layer 10 with a thickness of 7 cm. .

[0029] The preparation method of the filler filled with the iron-carbon micro-electrolytic layer 9 is as follows:

[0030] Weigh the raw...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is that the packing arrangement in the nitrate-nitrogen conversion bed is arranged successively from bottom to top as a 5cm pebble supporting layer 8, an iron-carbon micro-electrolysis layer 9 with a height of 50cm, and the upper layer is gravel with a thickness of 5cm Layer 10.

[0038] The preparation method of the filler filled with the iron-carbon micro-electrolytic layer 7 is as follows:

[0039] Weigh the raw materials according to the mass ratio, zero-valent iron powder: activated carbon powder: kaolin: copper powder: ammonium bicarbonate is 35:17:18:3:8 (can be weighed in g or kg), after mixing the raw materials evenly, add An appropriate amount of deionized water was stirred until suitable for granulation, and prepared into granules with a particle diameter of 15 mm. Dry the prepared granules in a vacuum drying oven at 105°C for 2 hours, then put the material into a vacuum tube furnace with nitrogen as a pro...

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is that the arrangement of fillers in the nitrate-nitrogen conversion bed from bottom to top is followed by a 10cm pebble supporting layer 8, an iron-carbon micro-electrolysis layer 9 with a height of 40cm, and an upper layer of gravel with a thickness of 10cm. Layer 10.

[0045] The preparation method of the filler filled with the iron-carbon micro-electrolytic layer 7 is as follows:

[0046] Weigh raw materials according to mass ratio, zero-valent iron powder: activated carbon powder: kaolin: copper powder: ammonium bicarbonate is 45:15:15:0.5:12 (can be weighed in g or kg), after mixing the raw materials evenly, add An appropriate amount of deionized water was stirred until suitable for granulation, and prepared into granules with a particle diameter of 20 mm. Dry the prepared granules in a vacuum drying oven at 105°C for 2 hours, then put the material into a vacuum tube furnace with nitrogen as a protective gas, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com