A method for separating spent acid using three-zone sequential simulated moving bed continuous chromatography

A technology of simulating moving bed and continuous chromatography, applied in the field of wastewater treatment and biological separation, can solve the problems of large water consumption, low salt removal rate, low separation degree, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

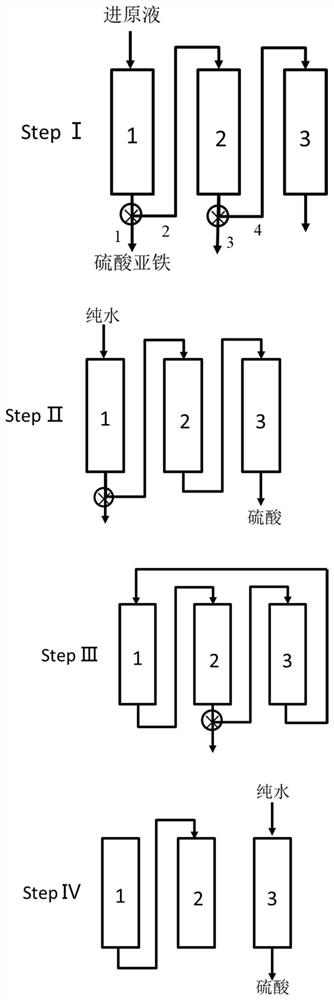

[0045] The three-zone SSMB continuous process unit separation system is adopted. Each resin column was filled with 0.6L resin (Tulsimer ), resin column diameter 5cm, height 40cm. The pretreated waste acid stock solution was loaded on the column, and deionized water was used as the eluent.

[0046] (1) The waste acid stock solution is injected at the inlet of the first column, the injection rate is 0.5BV / h, and the feed is 1BV. At the same time, the weakly retained component (ferrous sulfate) is collected at the first outlet of the first column until the effluent When the concentration of ferrous salt in the middle is 10% to 15% of the concentration of ferrous salt in the original ferrous salt-containing waste acid solution, stop collecting to obtain the effluent containing ferrous salt;

[0047] (2) At the end of step (1), continue to enter the eluting water at the inlet of the first column, the flow rate of the eluting water is 0.8BV / h, the consumption of eluting water is ...

Embodiment 2

[0050] Example 2: Continuous chromatographic separation of waste acid stock solution.

[0051] The three-zone SSMB continuous process unit separation system is adopted. Each resin column was filled with 0.6L resin (Tulsimer ), resin column diameter 5cm, height 40cm. The pretreated waste acid stock solution was loaded on the column, and deionized water was used as the eluent.

[0052] (1) The waste acid stock solution is injected at the inlet of the first column, the injection rate is 1BV / h, and the feed is 1BV. At the same time, the weakly retained component (ferrous sulfate) is collected at the first outlet of the first column until it is in the effluent When the concentration of ferrous salt is 10% to 15% of the concentration of ferrous salt in the original ferrous salt-containing waste acid solution, stop collecting to obtain the effluent containing ferrous salt;

[0053] (2) At the end of step (1), continue to enter the eluate at the inlet of the first column, the flow...

Embodiment 3

[0056] Example 3: Continuous chromatographic separation of waste acid stock solution.

[0057] The three-zone SSMB continuous process unit separation system is adopted. Each resin column was filled with 0.6L resin (Tulsimer ), resin column diameter 5cm, height 40cm. The pretreated waste acid stock solution was loaded on the column, and deionized water was used as the eluent.

[0058] (1) The waste acid stock solution is injected at the inlet of the first column, the injection rate is 1.5BV / h, and the feed is 1BV. At the same time, the weakly retained component (ferrous sulfate) is collected at the first outlet of the first column until the effluent When the concentration of ferrous salt in the middle is 10% to 15% of the concentration of ferrous salt in the original ferrous salt-containing waste acid solution, stop collecting to obtain the effluent containing ferrous salt;

[0059] (2) At the end of step (1), continue to enter the eluate at the inlet of the first column, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com