Process for separation of acid and salt in salt-containing waste acid

A technology of salt separation and acid in acid, which is applied to special treatment targets, water/sludge/sewage treatment, filtration treatment, etc., and can solve problems such as water expansion, complicated control, and small treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

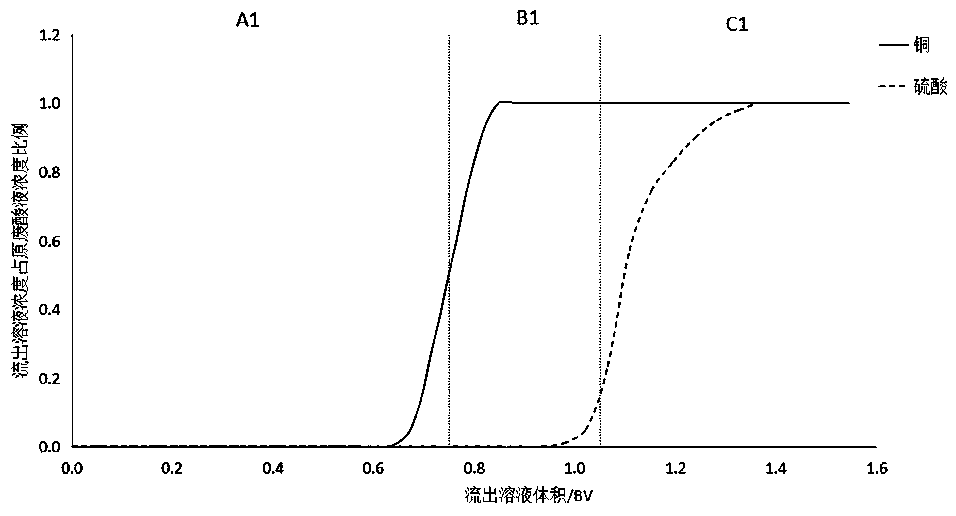

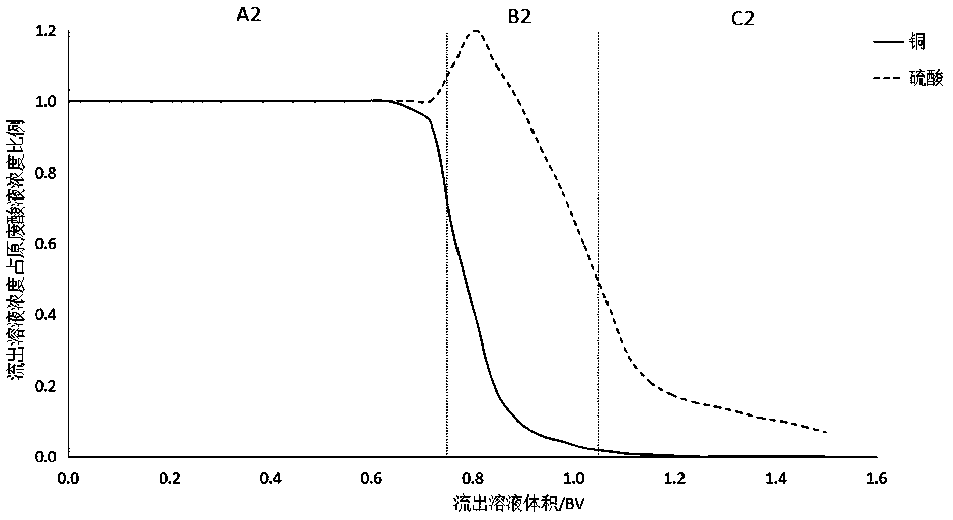

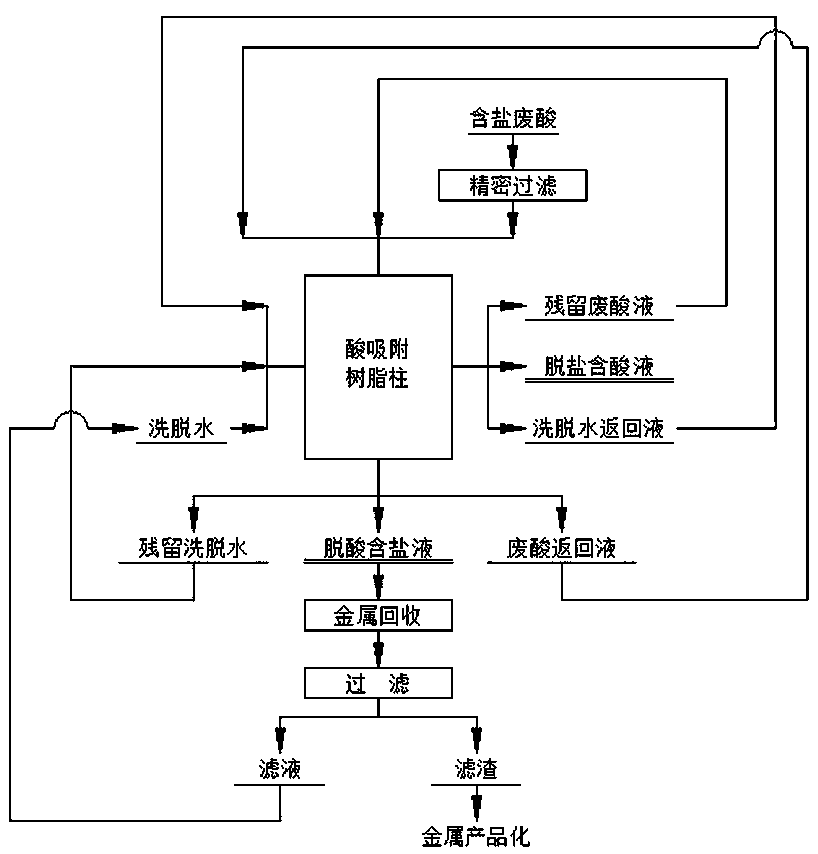

[0054] A kind of process of separating acid and salt in salt-containing waste acid of the present invention, this salt-containing waste acid adopts the waste electrolytic solution decoppered liquid of a certain copper smelter, contains sulfuric acid 245g / L, contains copper 14.7g / L, such as figure 1 Shown, technique of the present invention comprises the following steps:

[0055] (1) Before the first use, wash and elute the acid adsorption resin column with water. After finely filtering the salt-containing waste acid (copper-removed liquid) with a 1μm filter membrane, acid adsorption is carried out through an acid adsorption resin column filled with a strong basic anion exchange resin after washing with water. The acid adsorption resin column is equipped with an inner diameter Acid-absorbing resin of 5.5 cm x height 100 cm. The first cycle of adsorption is to pump the decopper liquid after precision filtration into the acid adsorption resin column from the bottom, and collect...

Embodiment 2

[0062] A process for separating acid and salt in salt-containing waste acid of the present invention uses the same salt-containing waste acid solution as in Example 1, the process is basically the same as in Example 1, the only difference is: only for the acid adsorption process The volume of the solution collected by adsorption and elution is changed. During the adsorption process, 1.8L of residual eluent water, 0.7L of deacidified salt solution and 0.7L of waste acid return solution are collected from the upper end in sequence. During the elution process, Collect 1.8L of residual waste acid solution, 0.7L of desalted acid solution and 0.7L of eluate return solution sequentially from the lower end.

[0063] Repeat the second cycle 3 times as well. Finally, the obtained average results are shown in Table 2 below.

[0064] Table 2 Concentration and separation rate of deacidified saline solution and desalted acid solution

[0065]

Embodiment 3

[0067] A process for separating acid and salt in salt-containing waste acid of the present invention uses the same salt-containing waste acid solution as in Example 1, the process is basically the same as in Example 1, the only difference is: only for the acid adsorption process The volume of the solution collected by adsorption and elution is changed. During the adsorption process, 1.8L of residual eluent water, 0.8L of deacidified salt solution and 0.6L of waste acid return solution are collected sequentially from the upper end. During the elution process, Collect 1.8L of residual waste acid solution, 0.7L of desalted acid solution and 0.7L of eluate return solution sequentially from the lower end.

[0068] Repeat the second cycle 3 times as well. Finally, the obtained average results are shown in Table 3 below.

[0069] Table 3 Concentration and separation ratio of deacidified saline solution and desalted acid solution

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com