Oily sludge treatment process method through biological method

A technology of sludge treatment and process method, which is applied in the direction of biological sludge treatment, sludge treatment, immiscible solvent sludge treatment, etc., and can solve the problems of oil resources not being recycled, high treatment costs, secondary pollution, etc. , to achieve the effect of resource recovery and harmless discharge, low treatment cost and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

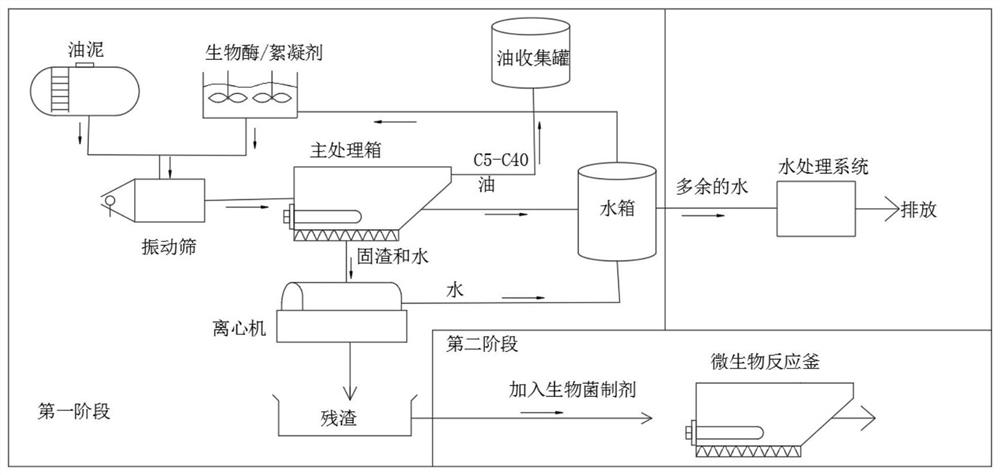

[0039] Please refer to Figure 1-2 as shown, figure 1 It is a schematic diagram of the installation of treatment equipment in a biological oily sludge treatment process, figure 2 It is a process flow of a biological oily sludge treatment process Figure 1 A biological method for oily sludge treatment process, comprising the following steps:

[0040] Step 1. Separating oil, water and solid residue.

[0041] Separation of oil, water and solid residue, including the following steps:

[0042] 101), put the biological enzyme and flocculant into the mixing box, then add water into the mixing box, and stir and mix to prepare a degreasing solution for later use, wherein the outlet end of the mixing box is connected to the inlet end of the vibrating screen through a pipeline.

[0043] 102), send the degreasing solution and sludge into the vibrating screen, start the vibrating screen, and screen the degreasing solution and sludge, wherein the sludge is stored in the sludge tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com