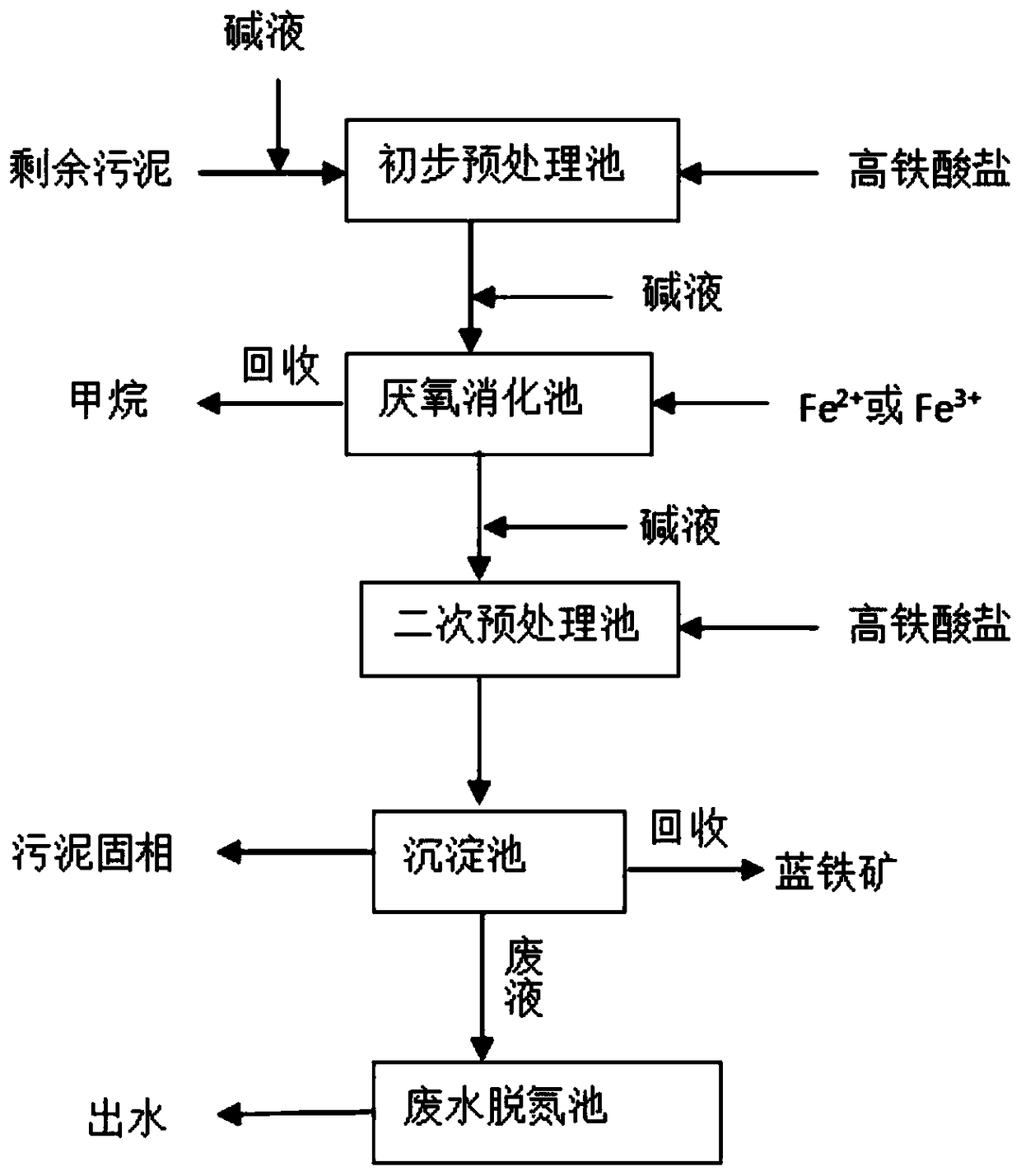

Ferrate-based excess activated sludge reduction and reclamation method

A technology of ferrate and residual activity, which is applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problem of resource recovery of substances in sludge, large use of ferrate, and cost High-level problems, to achieve the effect of improving oxidation efficiency, low treatment cost, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A 2 The / O process treats the remaining activated sludge in the sewage treatment plant of municipal sewage for reduction and resource recovery.

[0048] 1) Take 1000mL of the above-mentioned remaining activated sludge, and the concentration of MLSS is 10000mg / L. First adjust the pH of the sample to 11, then add fresh K 2 FeO 4 , the dosage is 40mg (Fe 6+ ) / gSS, maintain a stirring speed of 400rpm / min, carry out the first oxidation reaction, the duration is 1.5h, and obtain the preliminary pretreatment product.

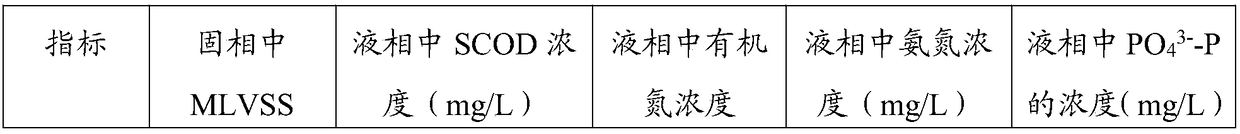

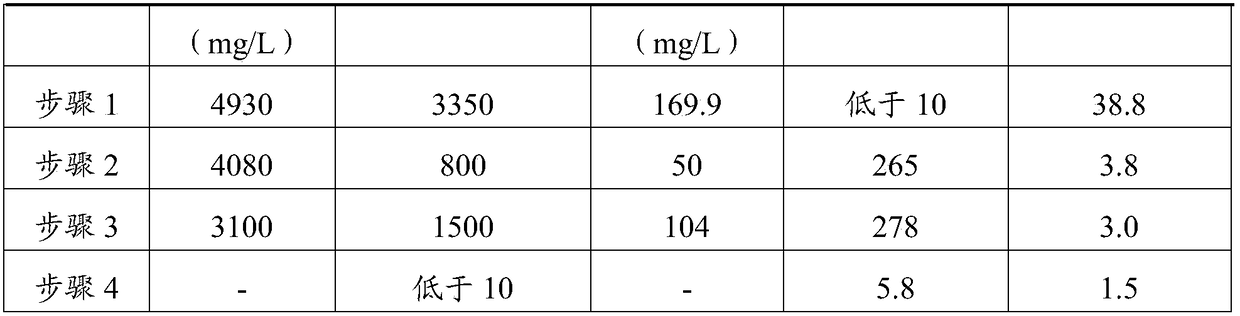

[0049] A small amount of mud-water mixture after preliminary pretreatment was taken for measurement. At this time, the MLVSS in the solid-phase sludge of the mud-water mixture was 4930mg / L. The concentration of SCOD in the liquid phase is 13350mg / L, the concentration of organic nitrogen is 1169.9mg / L, the concentration of ammonia nitrogen is lower than 10mg / L, PO 4 3- -P concentration is 38.8mg / L, Fe in solid phase is Fe 3+ form exists.

[0050] 2) Then ...

Embodiment 2

[0072] 1) Use the residual sludge of a municipal sewage treatment plant to treat sewage with oxidation ditch process for reduction and resource recovery. Take a sample of 2000mL, and the concentration of MLSS is 2000mg / L. Adjust the pH of the sludge to 11 for alkaline K 2 FeO 4 Pretreatment, that is, first adjust the pH of the sample to 11, and then add fresh K 2 FeO 4 , the dosage is 50mg (Fe 6+ ) / gSS, maintain a stirring speed of 400rpm / min, carry out the first oxidation reaction, the duration is 1.5h, and obtain the product after preliminary pretreatment.

[0073] Take a small amount of the product after preliminary pretreatment and separate it from water for measurement. At this time, the MLVSS in the solid phase sludge is 9930mg / L, and Fe is expressed as Fe 3+ The form exists; the concentration of SCOD in the liquid phase is 7280mg / L, the concentration of organic nitrogen is 390mg / L, the concentration of ammonia nitrogen is lower than 15mg / L, PO 4 3- The concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com