Method for preparing common glass by means of molten-state yellow phosphorus slag

A technology of yellow phosphorus slag and ordinary glass is applied in the field of preparing ordinary glass by using molten yellow phosphorus slag, which can solve the problems of difficulty in rapid continuous production, limited production technology, tedious and time-consuming, etc., and achieve the elimination of water resources and land resources. The use of resources, the realization of resource recovery, and the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

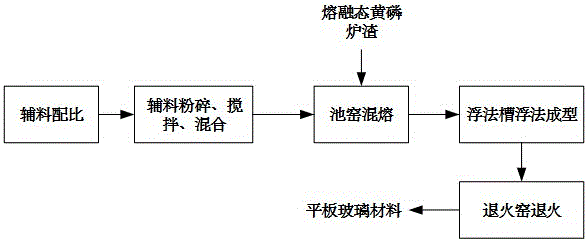

[0022] A process technology for preparing common glass materials from molten slag by float process, which comprises the following steps:

[0023] (1) Ratio of auxiliary materials: According to the chemical composition of the molten yellow phosphorus slag, the raw material formula for preparing common materials is determined, in which the molten yellow phosphorus slag (rich in CaO and SiO) 2 ) accounted for 50% of the total mass of raw materials, quartz powder auxiliary materials (rich in SiO 2 ) accounted for 40% of the total mass, kaolin auxiliary material (rich in Al 2 O 3 ) accounts for 10% of the total mass;

[0024] (2) Preparation of excipients: According to the proportion of excipients in step (1), the quartz powder excipients and kaolin excipients are weighed and then pulverized and evenly mixed. Stone (mainly composed of CaF 2 ) as a flux, and about 0.8% of the total mass of the raw material Sb 2 O 3 As a clarifying agent, the auxiliary material is modified to i...

Embodiment 2

[0030] A process technology for preparing common glass materials from molten slag by float process, which comprises the following steps:

[0031] (1) Ratio of auxiliary materials: According to the chemical composition of the molten yellow phosphorus slag, the raw material formula for preparing common materials is determined, in which the molten yellow phosphorus slag (rich in CaO and SiO) 2 ) accounted for 55% of the total mass of raw materials, quartz powder auxiliary materials (rich in SiO 2) accounted for 35% of the total mass, kaolin auxiliary material (rich in Al 2 O 3 ) accounts for 10% of the total mass;

[0032] (2) Preparation of auxiliary materials: According to the proportion of auxiliary materials in step (1), the quartz powder auxiliary materials and kaolin auxiliary materials are weighed and then pulverized and evenly mixed. (The main component is CaF 2 ) as a flux, and about 0.6% of the total mass of the raw material Sb 2 O 3 As a clarifying agent, the aux...

Embodiment 3

[0038] (1) Ratio of auxiliary materials: According to the chemical composition of the molten yellow phosphorus slag, the raw material formula for preparing common materials is determined, in which the molten yellow phosphorus slag (rich in CaO and SiO) 2 ) accounted for 60% of the total mass of raw materials, quartz powder auxiliary materials (rich in SiO 2 ) accounted for 35% of the total mass, kaolin auxiliary material (rich in Al 2 O 3 ) accounts for 5% of the total mass;

[0039] (2) Preparation of auxiliary materials: According to the proportion of auxiliary materials in step (1), the quartz powder auxiliary materials and kaolin auxiliary materials are weighed and then pulverized and evenly mixed. (The main component is CaF 2 ) as a flux, and about 0.6% of the total mass of the raw material Sb 2 O 3 As a clarifying agent, the auxiliary material is modified to improve the melting efficiency of the next step of mixing.

[0040] (3) Mixed melting: Add the auxiliary mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com