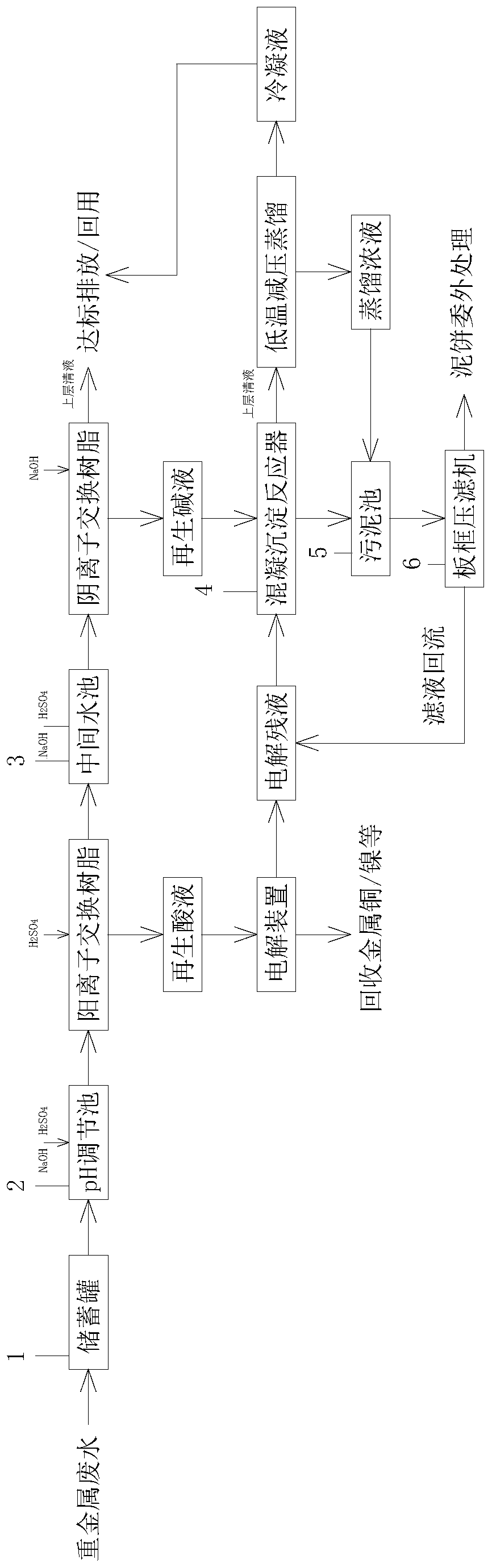

Heavy metal wastewater treatment process

A technology for wastewater treatment and heavy metals, which is applied in metallurgical wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of high heavy metal content, high effluent salt content, easy to block pipes, etc., and achieve high purity and high value. , the effect of reducing the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0023] see figure 1 , the embodiment of the present invention includes:

[0024] A heavy metal wastewater treatment process, the heavy metal wastewater treatment process comprises the following steps:

[0025] Step 1: collect electroplating copper-containing wastewater or electroplating nickel-containing wastewater and store them in the storage tank 1, pump the wastewater in the storage tank 1 into the pH adjustment pool 2, and add sodium hydroxide or sulfuric acid to the pH adjustment pool 2;

[0026] Step 2: After adjusting the pH in the pH adjustment tank 2, add cation exchange resin, which absorbs cations in wastewater. During the ion exchange proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com