Recovery method of rare earth elements in ionic rare earth smelting acid dissolution slag

An ionic rare earth and rare earth element technology, applied in the direction of improving process efficiency, can solve the problems of recovering rare earth elements in acid-soluble slag, affecting the recovery effect of rare earth in acid-dissolving slag, etc., to improve efficiency, reduce standards, and improve yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

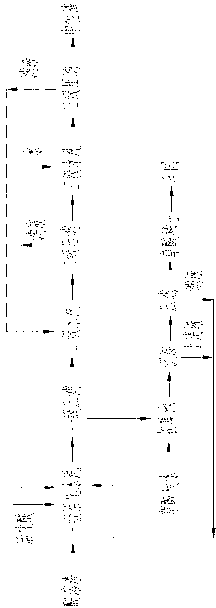

Image

Examples

Embodiment 1

[0024] Add activated acid to the acid-dissolved slag at a mass ratio of 10:1 to 20:1, add water at a mass ratio of 1:2 to 1:5, and perform primary activated water washing. After fully stirring for 1h to 3h, stop stirring and pass through the pump The feed liquid is poured into the plate and frame filter press for primary pressure filtration, and the acid-soluble slag is dehydrated for secondary water washing. The filtrate enters the collection tank and is mixed with oxalic acid wastewater to form oxalic acid rare earth precipitation. After the precipitation process, the oxalic acid rare earth precipitation is pumped The filtrate and the supernatant in the precipitation process are refluxed for primary activation water washing.

[0025] The acid-soluble slag after the first-stage pressure filtration and dehydration is subjected to the second-stage water washing, and the water is added according to the mass ratio of 1:2 to 1:5, and the pH is adjusted to <4 with hydrochloric a...

Embodiment 2

[0028] Acid-soluble slag: The acid-soluble slag produced by the acid-soluble process of an enterprise, the rare earth content, calculated by the total amount of rare earth oxides, namely REO, is 10.3%, the pH is 1.9, and the acid-soluble slag in stock is 2500m 3 , with an annual output of 300m acid-dissolved slag 3 .

[0029] The ratio (mass) of the dosage of activated acid to the acid-dissolved slag is 1:20, and the activated acid is prepared by concentrated hydrochloric acid (1+1) and perchloric acid whose p is 1.67g / ml, and the concentrated hydrochloric acid and perchloric acid The dosing ratio (mass ratio) is 1:4, the ratio (mass ratio) of water dosage to acid-dissolved slag is 2:1, and the washing and stirring time is set to 2h.

[0030] 1t of acid-dissolved slag, in which REO is calculated, the amount of rare earth elements is 0.103t, and 0.05t of activated acid is added according to the mass ratio of 20:1, and 2t of water is added according to the mass ratio of 1...

Embodiment 3

[0035] Acid-soluble slag: The acid-soluble slag produced by the acid-dissolving process of an enterprise, the rare earth content, calculated by the total amount of rare earth oxides, namely REO, is 12.6%, the pH is 2.1, and the acid-soluble slag in stock is 4000m 3 , with an annual output of 300m acid-dissolved slag 3 .

[0036] The ratio (mass) of the dosage of activated acid to the acid-dissolved slag is 1:10, and the activated acid is prepared by the concentrated nitric acid whose p is 1.42g / mL and the perchloric acid whose p is 1.67g / ml. The dosing ratio (mass ratio) of chloric acid is 1:5, the ratio (mass ratio) of water dosage to acid-dissolved slag is 5:1, and the washing and stirring time is set to 3h.

[0037]Add 0.1t of activated acid to 1t of acid-dissolved slag (the amount of rare earth elements is 0.126t in terms of REO) according to the mass ratio of 10:1, and add 5t of water according to the mass ratio of 1:5, perform primary activated water washing, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com