Treatment method for rare earth tailings

A treatment method and technology of rare earth tailings, applied in the field of rare earth tailings treatment, can solve the problems of low resource utilization, waste of resources, high cost, etc., and achieve the effects of low roasting temperature, short process flow and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

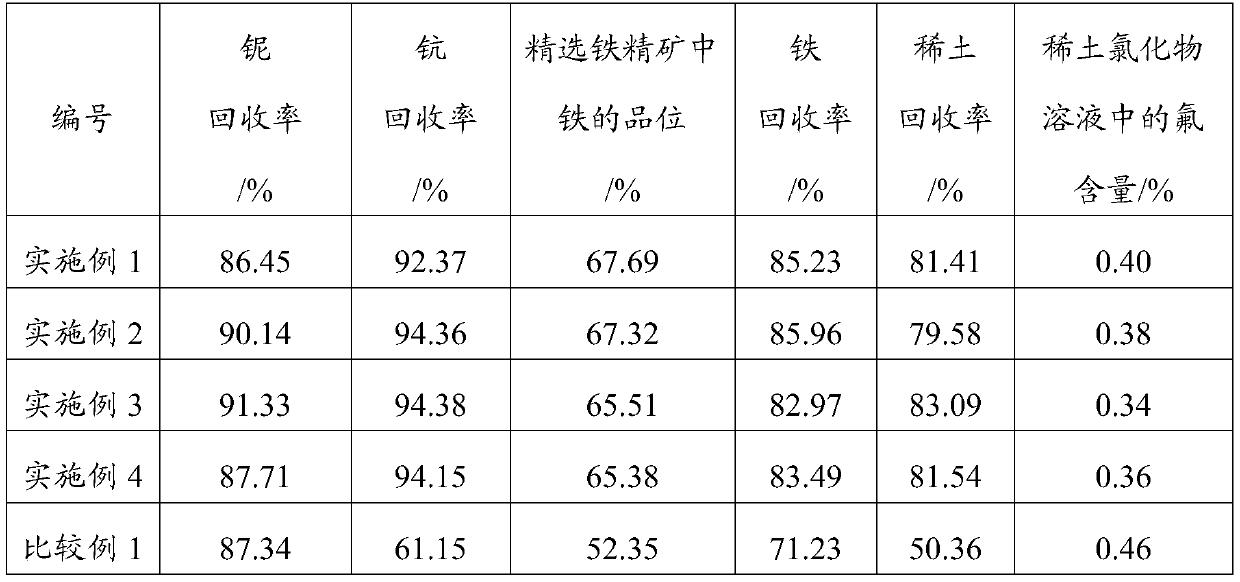

Examples

Embodiment 1

[0038] The composition of the rare earth tailings used is: iron grade (TFe) is 16.2%, rare earth REO grade is 6.0%, niobium grade (Nb 2 o 5 ) is 0.16%, scandium grade (Sc 2 o 3 ) was 0.011%, and the F content was 4.88%.

[0039] Dry the rare earth tailings at 90°C, grind and sieve to a particle size of 140-160 μm to obtain pretreated rare earth tailings; mix the pretreated rare earth tailings with calcium chloride, ammonium chloride, calcium oxide, oxidation Magnesium and anthracite are mixed uniformly at a weight ratio of 1:0.16:0.4:0.05:0.05:0.2 to obtain a mixed material; the mixed material is placed in a tube furnace and roasted at 600°C for 1.8h to obtain roasting flue gas and roasting scum. The roasting flue gas is cooled by a cooling device at 100°C to obtain niobium chloride (Nb 2 Cl 5 )product.

[0040] Dry-grind the roasted slag with a grinding fineness of -0.074mm56% to obtain the ground roasted slag; leaching the ground roasted slag with water at 90°C for 1....

Embodiment 2

[0044] The composition of the rare earth tailings used is: iron grade (TFe) is 16.71%, rare earth REO grade is 5.06%, niobium grade (Nb 2 o 5 ) is 0.11%, scandium grade (Sc 2 o 3 ) was 0.012%, and the F content was 3.96%.

[0045] Dry the rare earth tailings at 90°C, grind and sieve to a particle size of 140-160 μm to obtain pretreated rare earth tailings; mix the pretreated rare earth tailings with calcium chloride, ammonium chloride, calcium oxide, oxidation Magnesium and anthracite are mixed uniformly at a weight ratio of 1:0.1:0.3:0.04:0.05:0.2 to obtain a mixed material; the mixed material is placed in a tube furnace and roasted at 600°C for 2 hours to obtain roasting flue gas and roasting slag . The roasting flue gas is cooled by a cooling device at 150°C to obtain niobium chloride (Nb 2 Cl 5 )product.

[0046] Dry-grind the roasted slag with a grinding fineness of -0.074mm60% to obtain the ground roasted slag; leaching the ground roasted slag with water at 90°C f...

Embodiment 3

[0050] The composition of the rare earth tailings used is: iron grade (TFe) is 12.60%, rare earth REO grade is 5.11%, niobium grade (Nb 2 o 5 ) is 0.18%, scandium grade (Sc 2 o 3 ) was 0.014%, and the F content was 3.75%.

[0051] Dry the rare earth tailings at 95°C, grind and sieve to a particle size of 140-160 μm to obtain pretreated rare earth tailings; mix the pretreated rare earth tailings with calcium chloride, ammonium chloride, calcium oxide, oxidation Magnesium and anthracite are mixed uniformly at a weight ratio of 1:0.2:0.4:0.035:0.04:0.2 to obtain a mixed material; the mixed material is placed in a tube furnace and roasted at 650°C for 1.5h to obtain roasting flue gas and roasting scum. The roasting flue gas is cooled by a cooling device at 150°C to obtain niobium chloride (Nb 2 Cl 5 )product.

[0052] The roasted slag is subjected to dry grinding, the grinding fineness is -0.074mm57.3%, and the ground roasted slag is obtained; the ground roasted slag is lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com