Graded crushing and recovering method for waste batteries

A technology for graded crushing and used batteries, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of incomplete crushing, unevenness, high cost, etc., and achieve the effect of maximizing the value of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

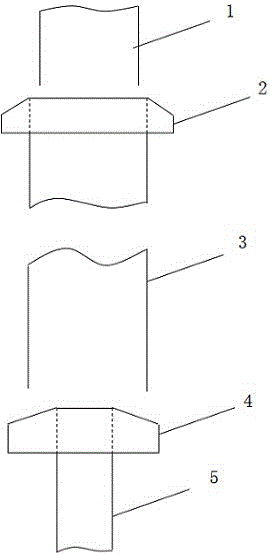

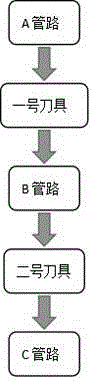

[0011] Specific experimental cases such as figure 2 , including the following steps:

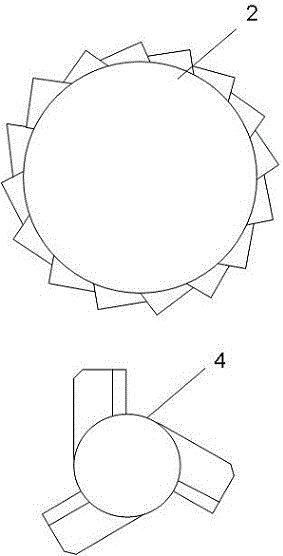

[0012] 1. Turn on the device, put the waste dry batteries that need to be processed into the crusher after soaking and de-charging, and the dry batteries will fall freely from the A pipeline (1) to the top of the No. 1 rotary cutter (2) under the action of gravity. The rotary cutter (2) performs primary crushing on the dry battery, removes the zinc cylinder on the surface of the dry battery, and the zinc cylinder is received by the corresponding receiving tool, and the primary crushing is completed. The No. 1 rotary cutter (2) is characterized in that the teeth of the rotary cutter are distributed on the circumferential surface, and it is a multi-edged rotary cutter. There is a circular hole in the middle of the cutter, which can break the zinc cylinder of the dry battery without destroying the internal structure of the battery. Realize single crushing.

[0013] 2. Then, the broken dry ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com