Energy-saving and environment-friendly construction waste regenerated aggregate device and treatment method

A technology of construction waste and recycled aggregates, applied in the direction of grain processing, etc., can solve the problems of dust flying environment, pollution, large land expropriation fees, garbage removal and transportation costs, construction funds, etc., and achieve the effect of ensuring the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

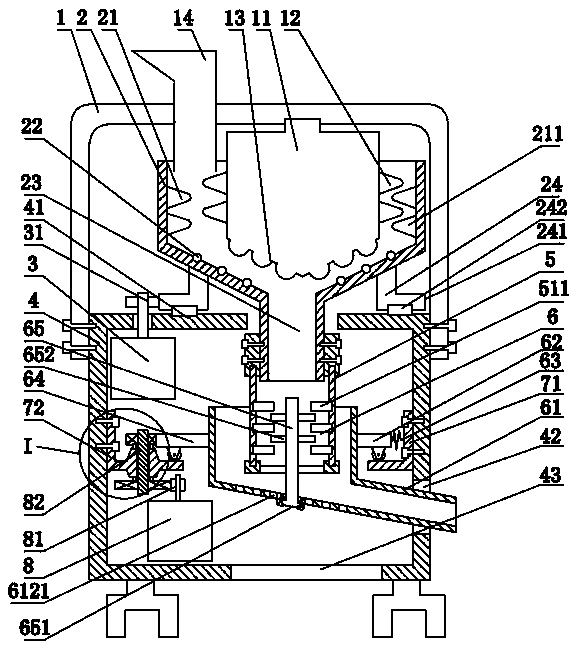

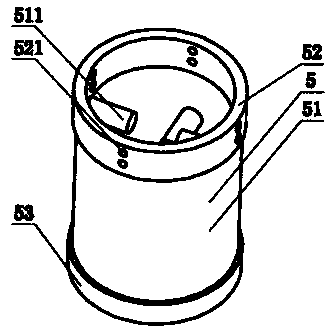

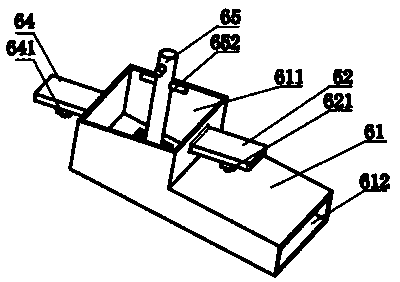

[0032] like Figure 1 to Figure 6 As shown, according to an energy-saving and environment-friendly construction waste recycling aggregate device of the present embodiment 1, it includes an upper hood 1, a lower hood 4, a rotating funnel 2, a rotating motor 3, a lower crushing pipe 5 and a screening tank 6, The upper hood 1 is fixedly connected with the lower hood 4 , an extrusion body 11 is fixed on the right inner wall of the top of the upper hood 1 , a feeding channel 14 is installed in the middle of the top, and the edge of the extrusion body 11 is provided with an extrusion body 11 . There are side extrusion protrusions 12 and a bottom extrusion protrusion 13 at the bottom. The rotating funnel 2 includes a funnel body 21, and the feeding channel 14 and the extrusion body 11 both extend into the funnel body 21. The extrusion body 11 is located on the right side of the rotating funnel 2, the lower part of the funnel body 21 is installed with a drive wheel 24, a bearing 242 i...

Embodiment 2

[0047] According to an energy-saving and environment-friendly construction waste recycling aggregate processing method of the second embodiment, the energy-saving and environment-friendly construction waste recycling aggregate device is applied, and the processing method includes the following steps:

[0048] First, the material is added from the feeding channel 14, and the driving wheel 24 is driven by the rotary motor 3 to realize the overall rotation of the rotary funnel 2. After the material enters the rotary funnel 2, it is squeezed and crushed between the rotary funnel 2 and the extrusion body 11; then, The material flows into the lower crushing pipe 5 through the blanking outlet 23. Since the lower crushing pipe 5 rotates with the rotating funnel 2, the material in the lower crushing pipe 5 can be squeezed by the staggered swing protrusions 652 and the crushing rod 511 again. , to achieve secondary crushing; the material after secondary crushing falls into the blanking c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com