Tooth-claw type crusher

A pulverizer and claw technology, applied in the field of feed processing, can solve the problems of high power consumption, low work efficiency, and easy spontaneous combustion, etc., and achieve the effects of long service life, improved crushing efficiency, and good space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

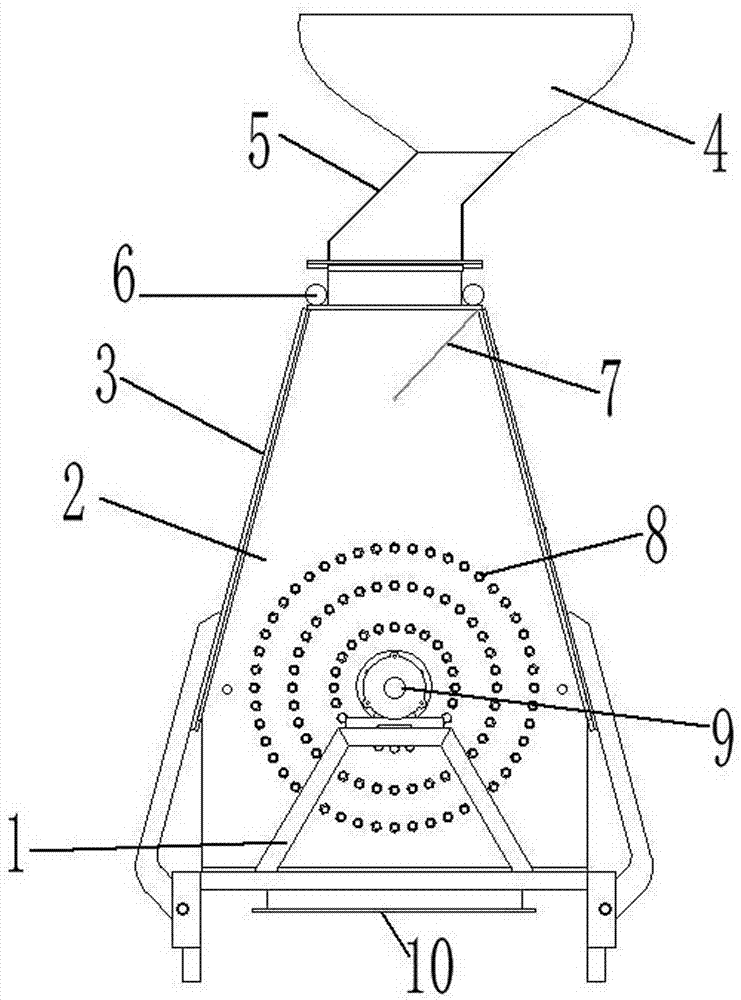

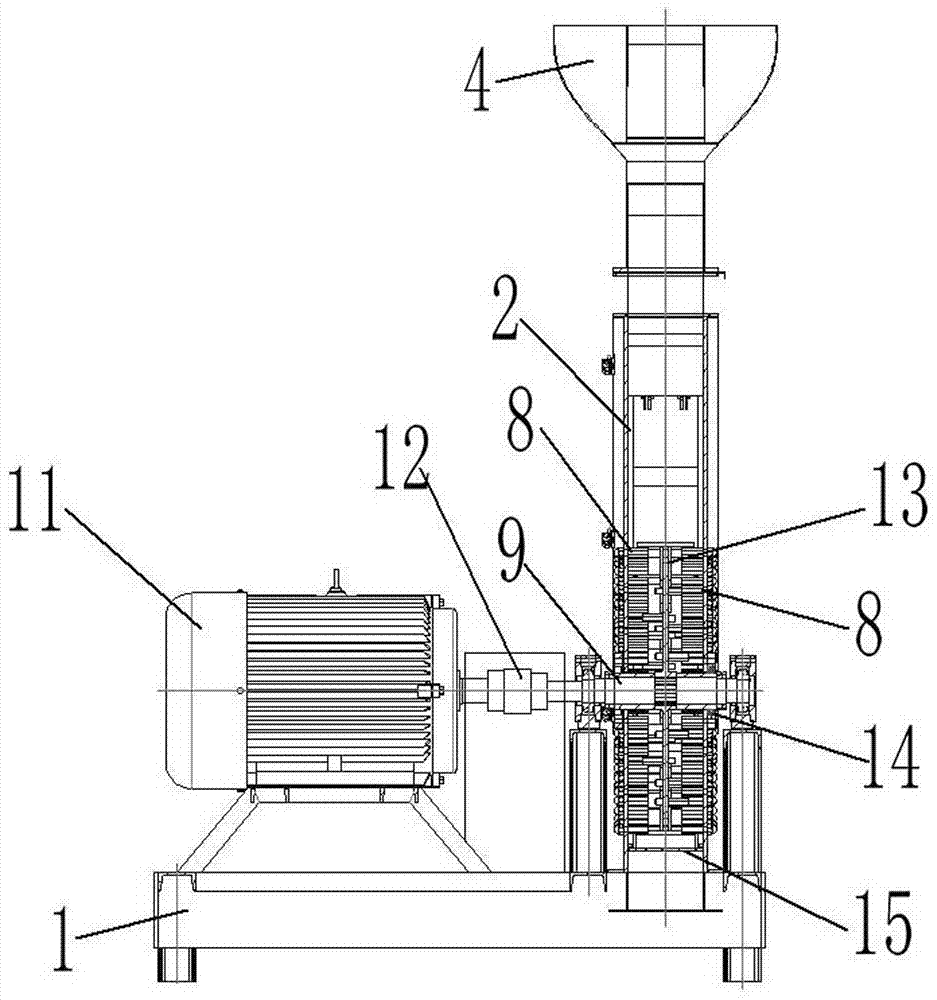

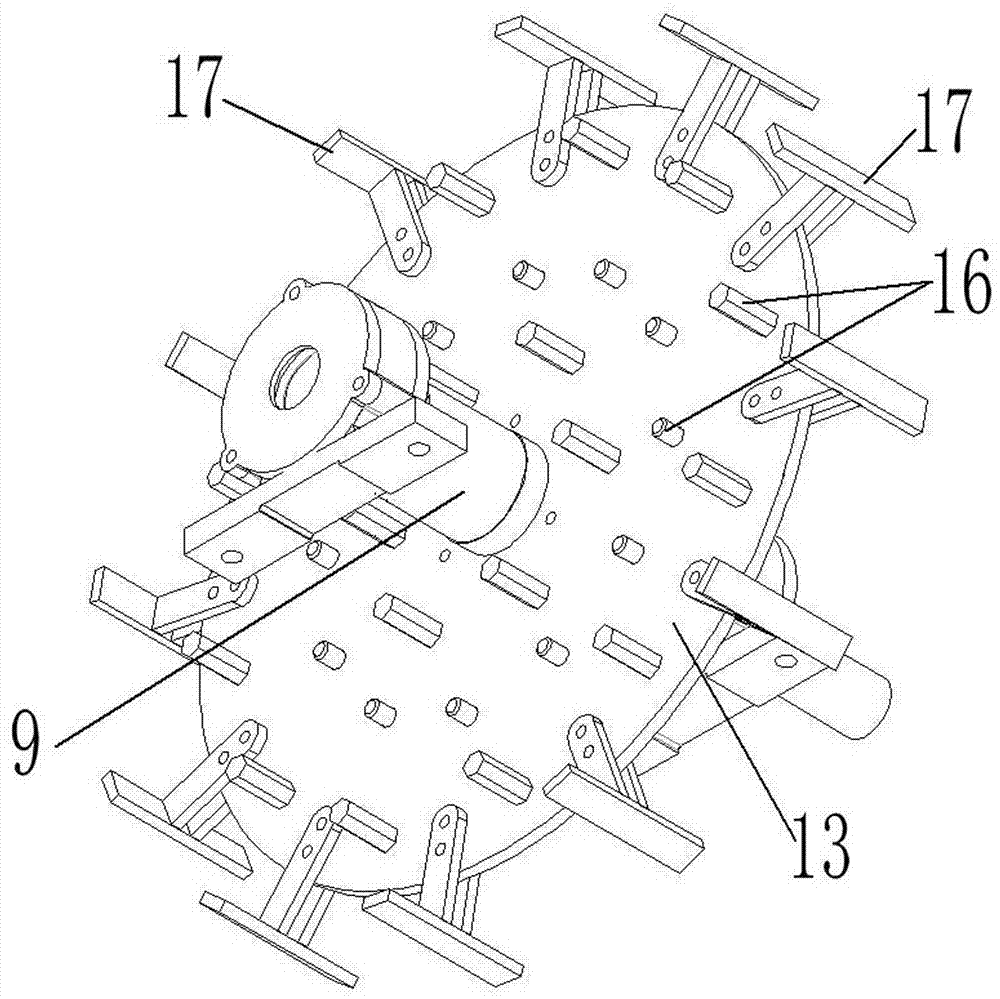

[0028] Attached below figure 1 to attach Figure 4 The present invention will be further described.

[0029] A claw-type pulverizer, comprising: a machine base 1; a casing 2, which is installed on the machine base 1, and is provided with a closed cavity inside, and the upper end of the casing 2 is provided with a feed port 18 connected to the cavity, The lower end is provided with a discharge port 10 connected to the cavity; the feed hopper 4 is installed on the casing 2, and its lower end is connected with the feed port 18; The longitudinal rotation is installed in the cavity inside the housing 2; the motor 11 is installed on the machine base 1, and its output shaft is connected with a main shaft 9 through a coupling 12; several claws II 16, and the rotor disk 13 or so The claws II 16 at both ends are arranged on the end face of the rotor disk 13 in the form of M concentric circles, M is a natural number greater than or equal to 2; a number of claws I 8, each claw on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com