Two-stage raw material crushing device for industrial production of zinc sulfate

A technology of secondary crushing and zinc sulfate, applied in the direction of grain processing, etc., can solve the problems of inability to determine the particle size, uncontrollable crushing size, inability to limit the size of crushed particles, etc., to achieve the effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

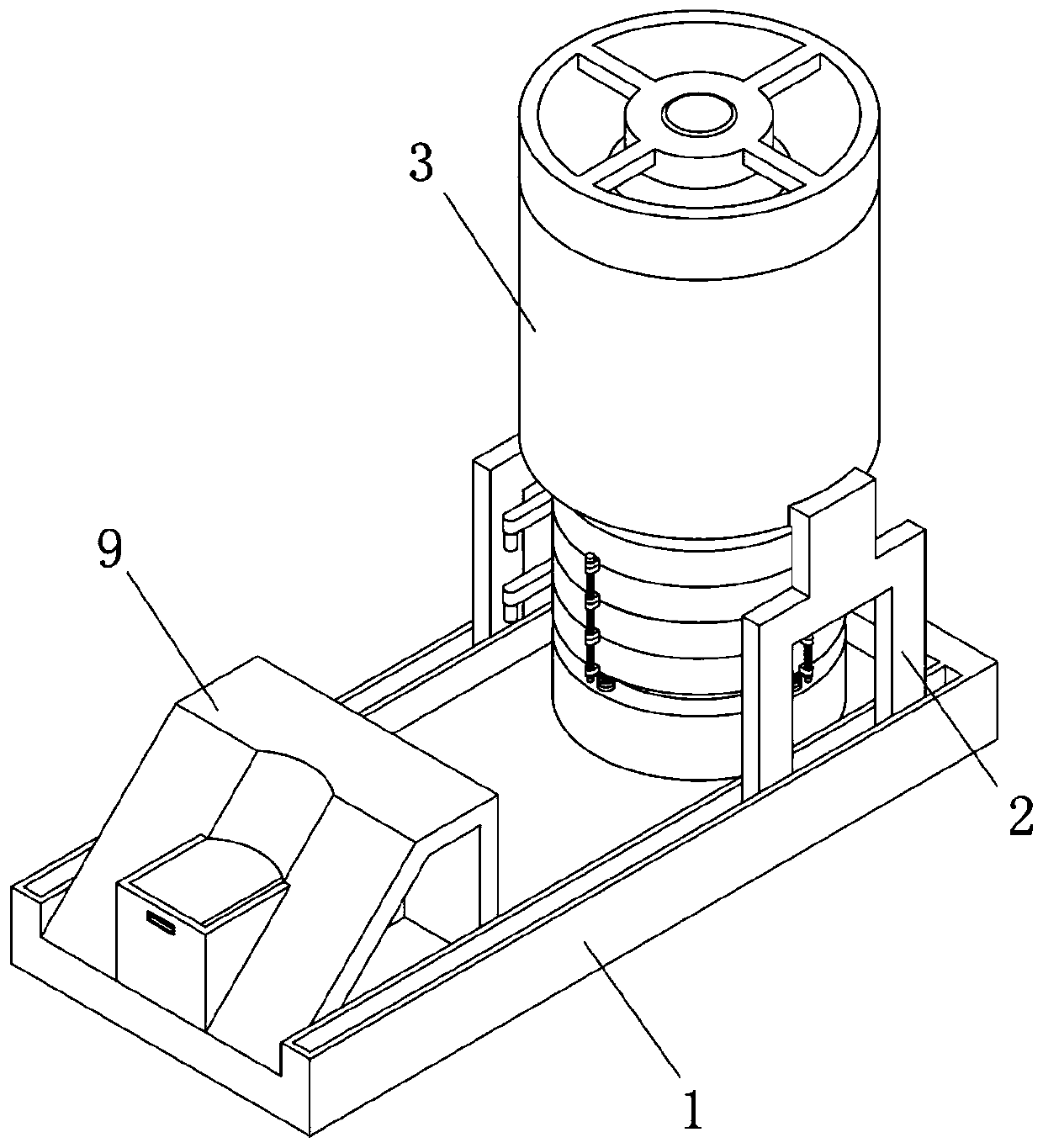

[0023] refer to figure 1 , image 3 and Figure 4 The provided secondary crushing device for raw materials for industrial production of zinc sulfate comprises an installation substrate 1, a crushing box 3 that can be displaced and adjusted on the installation substrate 1, and a blanking structure arranged on the installation substrate 1 to match the crushing box 3;

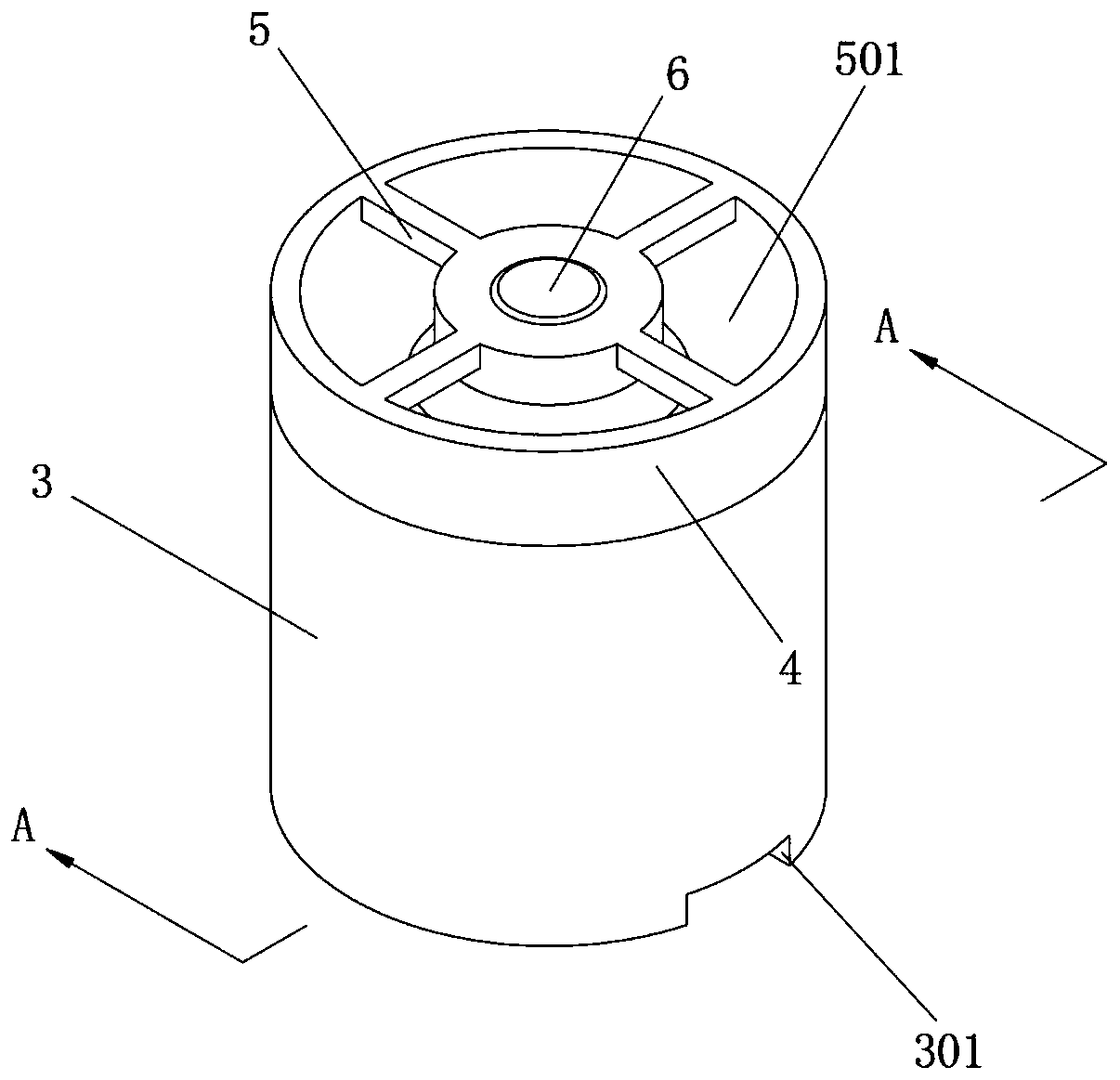

[0024] The crushing box 3 is a cylindrical structure, and a set of crushing bins 7 are opened at the top of the crushing box 3. The edge of the crushing bin 7 is configured as a conical side wall (the conical side wall is convenient for the falling of raw materials) , and the bottom end is provided with a feeding cavity that communicates with the outside, the top end of the crushing bin 7 is covered with a set of closing covers 4, and the feeding cavity at the bottom end of the crushing bin 7 is closed by a closed gate 12 (in specific implementation, the closed gate is 12 models and formats are selected accordin...

Embodiment 2

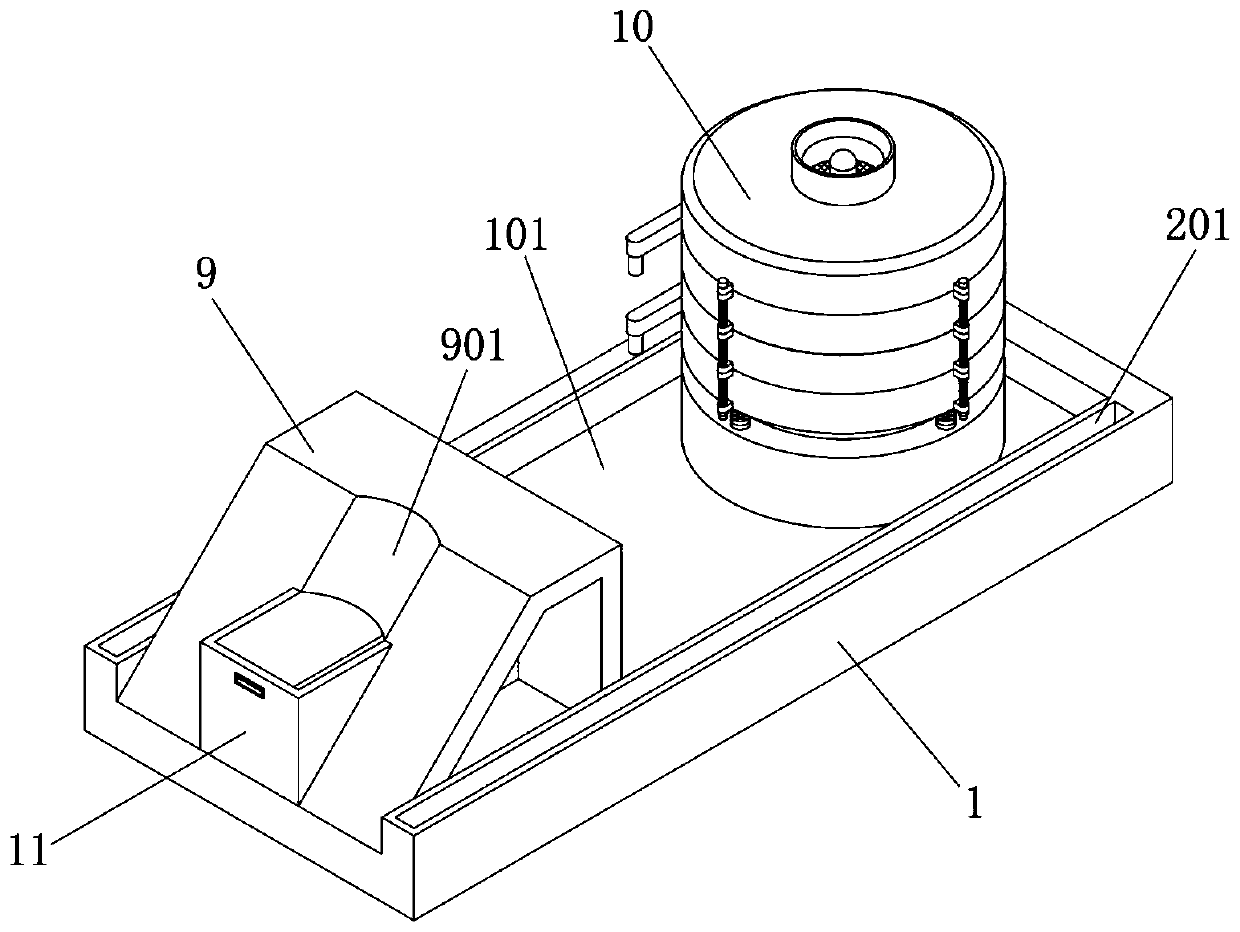

[0031] refer to figure 1 and figure 2 The provided secondary crushing device for raw materials for industrial production of zinc sulfate includes an installation substrate 1, a crushing box 3 that can be displaced and adjusted on the installation substrate 1, and a blanking structure arranged on the installation substrate 1 to match the crushing box 3, Both sides of the bottom end of the crushing box 3 are provided with connecting grooves 301 for connecting the movable support frame 2. The bottom end of the movable support frame 2 is divided into two groups of plate-like structures connecting the rollers, and the two sides of the mounting base plate 1 are opened. There is a chute 201 for the bottom roller of the movable support frame 2 to install and slide. The crushing box 3 supported by the movable support frame 2 can move relative to the installation base plate 1. When the crushing box 3 moves to the top of the blanking plate 9, it can be moved. Realize the unified blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com