Method for removal of lead ions in sewage by mycobacterium phlei

A technology of Mycobacterium phlei and lead ions is applied in the field of heavy metal ion treatment in sewage, which can solve the problems such as the inability to achieve the recycling of adsorbents and heavy metals, and the limited number of heavy metal ions, and achieve good adsorption and removal effect, good social benefits and economic benefits. Efficient and easy to use in industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

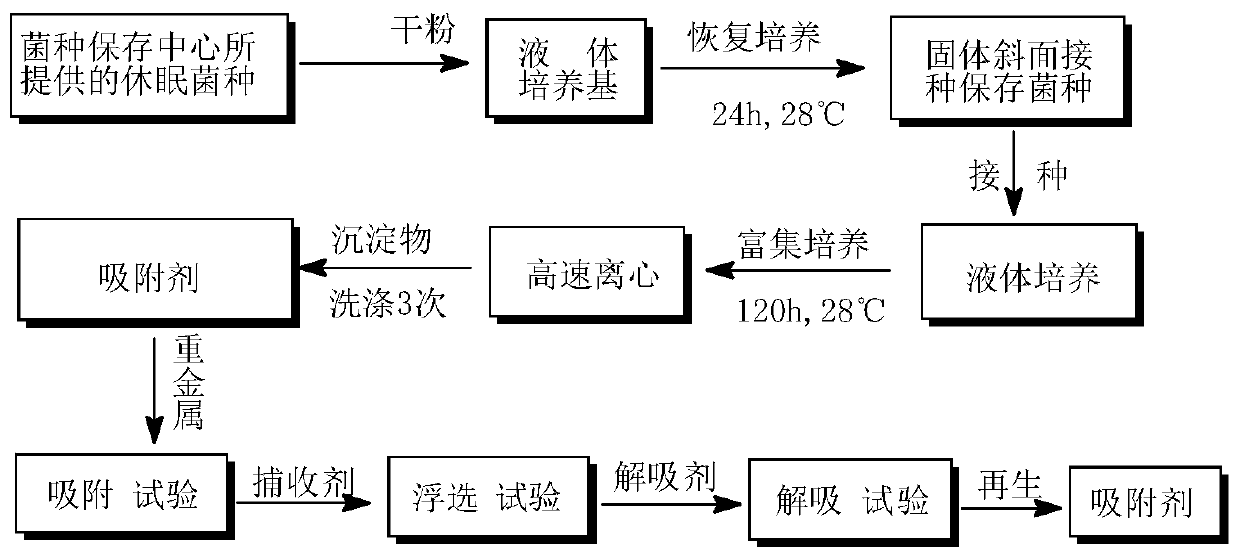

Method used

Image

Examples

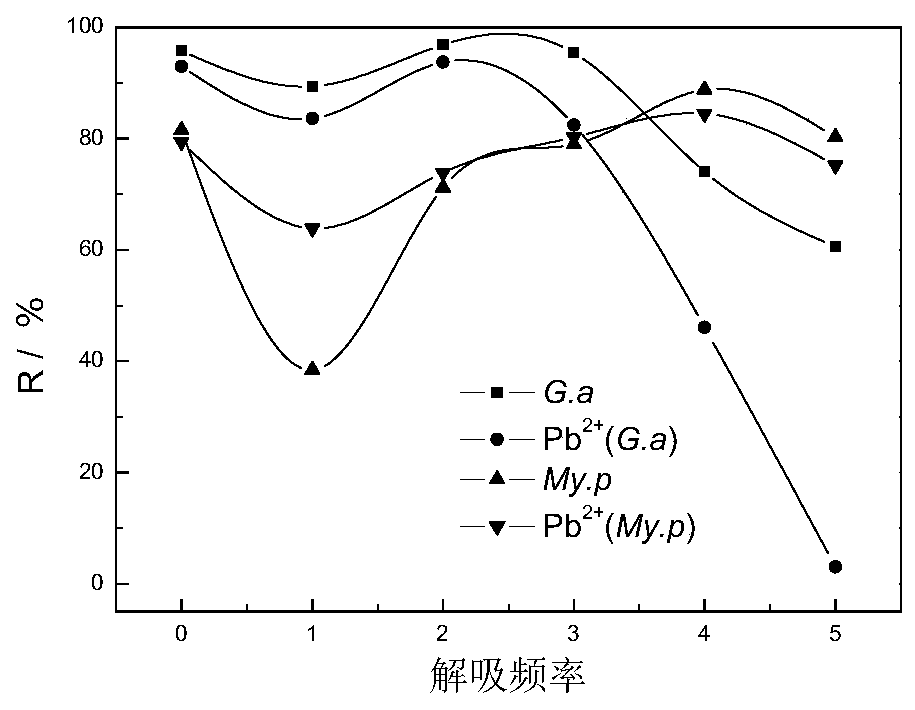

Embodiment 1

[0050] The adsorption process of microbial adsorbent Mycobacterium phlei to copper ions in wastewater: add the obtained microbial adsorbent wet cells at a dosage of 9.0g / L to the flotation tank containing 60-200mg / L lead ion aqueous solution, The pH of the sewage is 4.0~7.0. After adding the wet cells of the microbial adsorbent, the flotation tank is stirred and adsorbed for 10 minutes, and then the saturated adsorbed microbial adsorbent is recovered and separated by flotation in the flotation tank. The stirring speed is 100-200r / min , pH=4.0~7.0, add 0.06mg / L dodecylamine to the Mycobacterium phlei suspension for 8min flotation, put the flotation recovered bacteria residue into 200mg / L sodium carbonate solution for desorption Regeneration, after the microbial adsorbent is regenerated and used for 4 times, the lead ion content in the water is lower than 40.0mg / L, and the concentration of the bacterial suspension in the flotation tank is reduced to below 0.01mg / L. Take the tail...

Embodiment 2

[0055] The effect of adding alkali metal cation solution in the flotation tank on the adsorption effect of the microbial adsorbent Mycobacterium phlei on the adsorption of lead ions in wastewater: the obtained microbial adsorbent wet cells were added to 60 In the flotation cell of -200mg / L lead ion aqueous solution, the pH of the sewage is 4.0~7.0, after adding the wet cells of the microbial adsorbent, add 5.3mg / L NH 4 Cl solution, the flotation tank was stirred and adsorbed for 10min. After the adsorption, the lead ion content in the water was lower than 20.0mg / L, and then the saturated adsorption microbial adsorbent was recovered and separated by flotation in the flotation tank. The stirring speed was 100-200r / min , pH=4.0~7.0, add 0.06mg / L collector dodecylamine to the suspension of Mycobacterium phlei, and after 8 minutes of flotation to recover the saturated microbial absorbent, the bacterial suspension in the flotation tank The concentration dropped below 0.01mg / L. Take...

Embodiment 3

[0060] Add the obtained microbial adsorbent wet cells into the flotation tank containing 60-200mg / L lead ion aqueous solution at a dosage of 9.0g / L. The pH of the sewage is 4.0~7.0. After putting in the microbial adsorbent wet cells, add NaCl solution 60.0mg / L and MgCl 2 Solution 95.0mg / L, the flotation tank was stirred and adsorbed for 10min, the lead ion content in the water after adsorption was lower than 20.0mg / L, and then the saturated adsorption microbial adsorbent was recovered and separated by flotation in the flotation tank, at a stirring speed of 100- Under the condition of 200r / min and pH=4.0~7.0, add 0.06mg / L collector dodecylamine to the bacterial suspension of Mycobacterium phlei, and recover the saturated microbial absorbent by flotation for 8min. The concentration of the bacterial suspension dropped below 0.01mg / L. Take the tail liquid in the flotation tank, and drain it after passing the test.

[0061] In the present invention, the collector dodecylamine cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com