Recycling system for treating slaughter wastewater

A technology for recycling slaughter wastewater, applied in filtration treatment, multi-stage water treatment, aerobic process treatment, etc., can solve the problems of low treatment efficiency, waste of resources, complex components, etc., to increase the content of soil organic matter and maintain good fertilizer Sex, increase the effect of self-purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of matrix filler: take rice straw and put it into a pulverizer for crushing, pass the crushed material through a 50-mesh sieve, collect the sieved particles, put the sieved particles into a press, and squeeze them at 20MPa for 10-15 minutes, then squeeze Put the compressed material into a tubular carbonization furnace, set the temperature at 400-430°C, carbonize for 3-5 hours, and collect the carbonized material; according to the mass ratio of 8:3:2-8:5:2, take the above-mentioned carbonized material, rapeseed cake and The wheat straw is put into a straw grinder for crushing, passed through a 30-mesh sieve, and the sieved matter is collected to obtain the matrix filler.

[0029] Preparation of sunken stone filler: According to the mass ratio of 4:3:1, take vermiculite, river pebble and feldspar and put them into a pulverizer for crushing, pass through a 30-mesh sieve, and collect the sieved particles to obtain sunken stone filler.

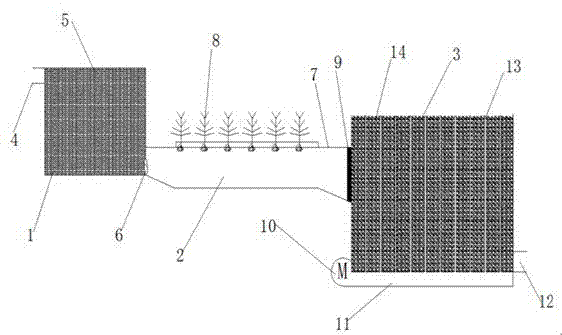

[0030] Such as figure 1 ...

example 1

[0032] The invention constructs an ecological zone, prepares a matrix filler and a sinking stone filler, and the slaughter wastewater is treated through the substrate zone 1, the ecological zone 2 and the sinking stone zone 3 in sequence.

[0033] The process of the present invention is as figure 1A recycling system for treating slaughter wastewater is shown, which is composed of matrix area 1, ecological area 2 and sinking stone area 3. After the slaughter wastewater enters the matrix area through the wastewater inlet 4 on the upper part of the matrix area 1, it passes through the matrix area 1. The inner matrix filler 5 filters the solid particles of the slaughter wastewater and pretreats the substances in the slaughter wastewater. After the pretreatment of the slaughter wastewater is completed, the matrix filler 5 is used as a fertilizer, and the pretreated slaughter wastewater passes through The stainless steel filter screen port 6 at the bottom of the matrix area 1 enters...

example 2

[0039] The invention constructs an ecological zone, prepares a matrix filler and a sinking stone filler, and the slaughter wastewater is treated through the substrate zone 1, the ecological zone 2 and the sinking stone zone 3 in sequence.

[0040] The process of the present invention is as figure 1 A recycling system for treating slaughter wastewater is shown, which is composed of matrix area 1, ecological area 2 and sinking stone area 3. After the slaughter wastewater enters the matrix area through the wastewater inlet 4 on the upper part of the matrix area 1, it passes through the matrix area 1. The inner matrix filler 5 filters the solid particles of the slaughter wastewater and pretreats the substances in the slaughter wastewater. After the pretreatment of the slaughter wastewater is completed, the matrix filler 5 is used as a fertilizer, and the pretreated slaughter wastewater passes through The stainless steel filter mesh port 6 at the bottom of the matrix area 1 enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com