Method for recycling lithium iron phosphate/ternary-lithium titanate batteries

A lithium titanate battery and lithium iron phosphate technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of unclean, dead lithium, and difficulty in preparing lithium battery negative electrode materials, etc., to achieve the method Simple, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

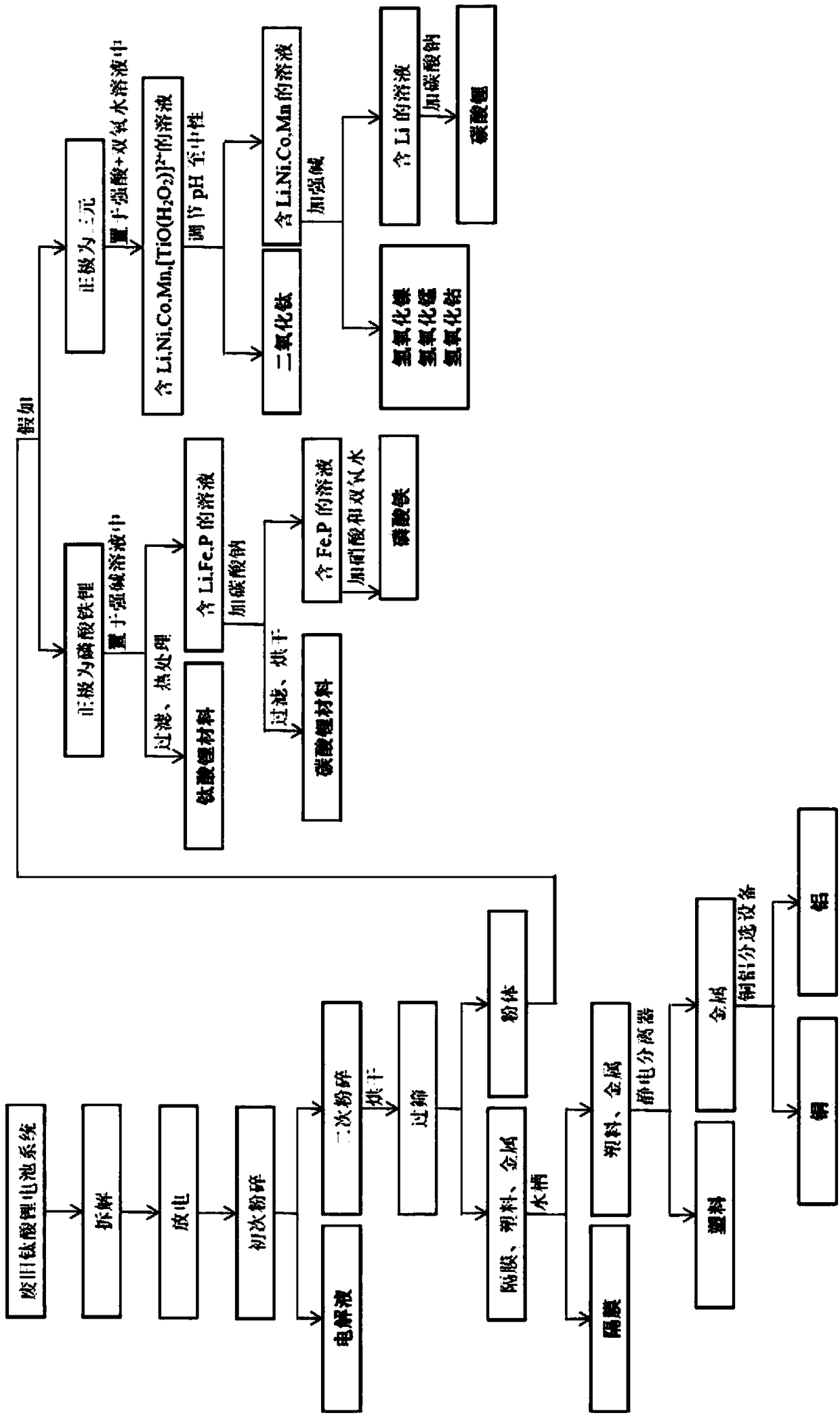

Image

Examples

Embodiment 1

[0029] Taking the lithium iron phosphate-lithium titanate waste battery pack as an example, the recycling method is shown in the following steps:

[0030] 1. Dismantling: Mechanically disassemble the shell, BMS board, electrical wiring, screws and nuts, sensors, air cooling / liquid cooling system and other metal and plastic parts of the waste lithium titanate battery system, and sort them into warehouses.

[0031] 2. Discharge: Submerge the remaining lithium titanate battery system / module / monomer in 3.5% NaCl aqueous solution until fully discharged. Among them, the remaining lithium titanate battery system / module means that the mechanical disassembly may not be disassembled to the module level, or may be disassembled to the monomer, which needs to be disassembled according to the actual situation.

[0032] 3. Pulverization: (1) put it in a crusher and crush it into particles / fine pieces of 0-5cm level; (2) then put it in a pulverizer and pulverize it into fine powder of 0-3mm l...

Embodiment 2

[0042] Taking the waste ternary-lithium titanate battery pack as an example, the recycling method is shown in the following steps:

[0043] 1. Dismantling: Mechanically disassemble the shell, BMS board, electrical wiring, screws and nuts, sensors, air cooling / liquid cooling system and other metal and plastic parts of the waste lithium titanate battery system, and sort them into warehouses.

[0044] 2. Discharge: Submerge the remaining lithium titanate battery system / module / monomer in 3.5% NaCl aqueous solution until fully discharged. Among them, the remaining lithium titanate battery system / module means that the mechanical disassembly may not be disassembled to the module level, or may be disassembled to the monomer, which needs to be disassembled according to the actual situation.

[0045] 3. Pulverization: (1) put it in a crusher and crush it into particles / fine pieces of 0-5cm level; (2) then put it in a pulverizer and pulverize it into fine powder of 0-3mm level.

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com