Machine tool chip removal and cleaning device for numerical control machine tool

A technology of CNC machine tools and cleaning devices, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of time-consuming, labor-intensive and low efficiency of machine tool debris, achieve convenient recycling and improve cleaning efficiency , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

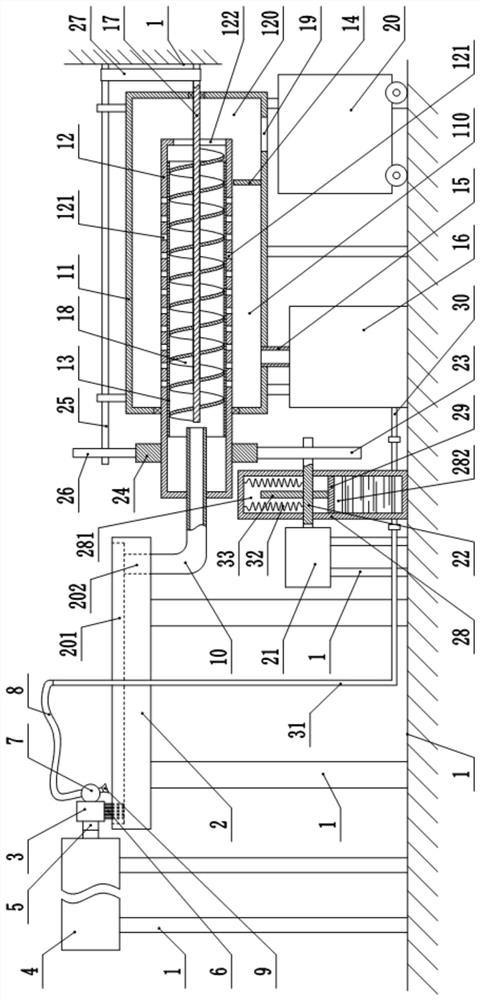

[0031] This embodiment is basically as figure 1 Shown: a machine chip cleaning device for CNC machine tools, including a frame 1, a recovery mechanism and a cleaning mechanism located above the CNC machine tool 2, the cleaning mechanism includes a moving plate 3 and a drive assembly for driving the moving plate 3 to move , in this embodiment, the driving assembly one includes a hydraulic cylinder 4 and a push rod 5, the hydraulic cylinder 4 is fixedly mounted on the frame 1 by bolts, the output end of the hydraulic cylinder 4 is fixedly connected with the push rod 5 by bolts, and the push rod 5 The right end is welded with the mobile plate 3.

[0032] The bottom surface of the moving plate 3 is bonded with a cleaning brush 6 corresponding to the groove 201 on the CNC machine tool 2, and the right side wall of the moving plate 3 is welded with a flushing pipe 7, which is connected with a liquid inlet hose 8 and several Nozzle 9, in this embodiment, each groove 201 corresponds ...

Embodiment 2

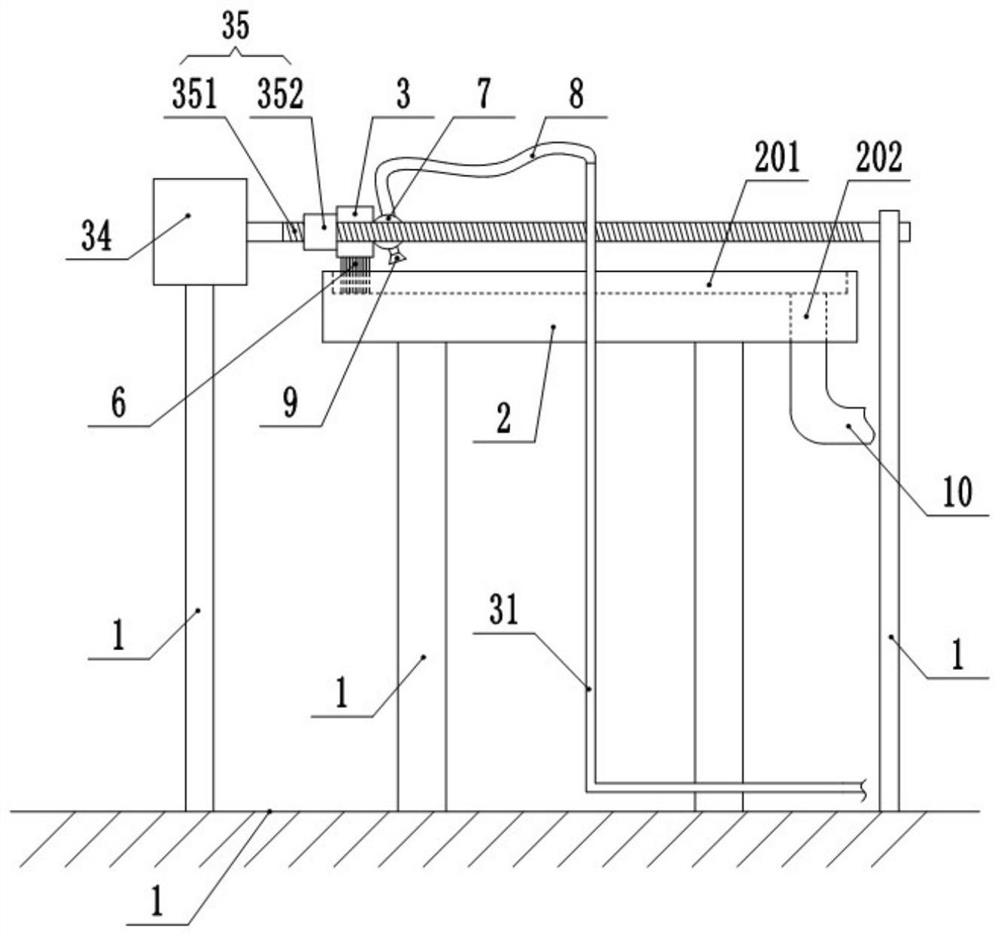

[0044] The difference between this embodiment and Embodiment 1 is that: figure 2 As shown, the drive assembly one includes two motors one 34 and two ball screw pairs 35 ( figure 2 Among them, two motors 34 and two ball screw pairs 35 are all arranged front and rear, therefore, only one motor 34 and a pair of ball screw pairs 35 can be seen), and the output end of motor 1 34 is located on the same side as The leading screw 351 of the ball screw pair 35 is connected, and the nut 352 of the ball screw pair 35 is welded with the moving plate 3 . Motor one 34 and motor two 21 ( figure 1 Middle) in series in the same electrical circuit.

[0045] In this embodiment, since the first motor 34 and the second motor 21 are connected in series in the same electrical circuit, the first motor 34 and the second motor 21 can be turned on and off at the same time, reducing the amount of work for workers. When motor one 34 starts, motor one 34 drives the leading screw 351 of ball screw pair...

Embodiment 3

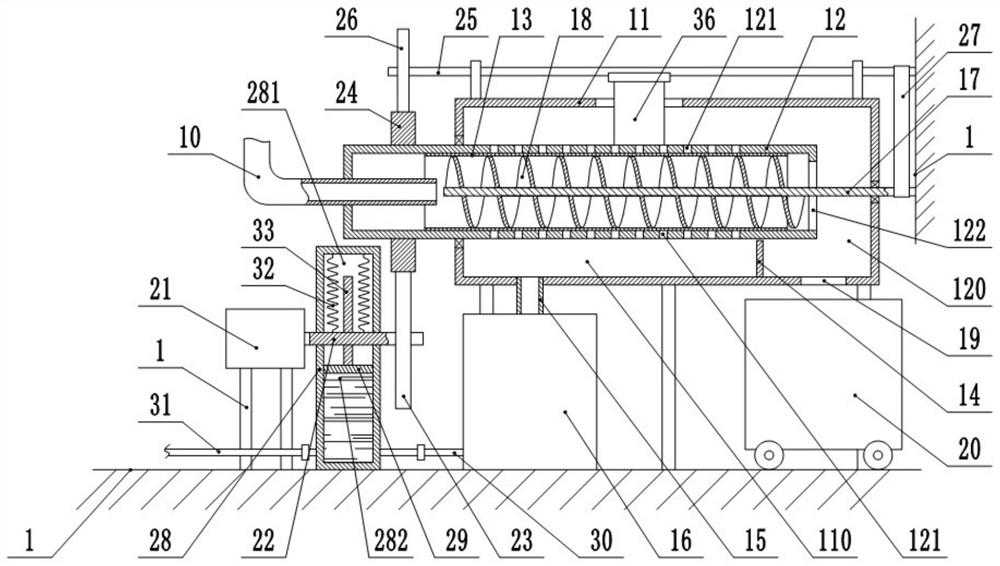

[0047] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, the middle part of the third rotating shaft 25 is hinged with an impact plate 36 , specifically, in this embodiment, the impact plate 36 is hinged on the third rotating shaft 25 through a hinge. The outer surface of the impact plate 36 is bonded with a rubber layer, and the top of the cylinder 11 is provided with an arc-shaped groove for the impact plate 36 to rotate.

[0048] In this embodiment, during the clockwise rotation of the rotating shaft 3 25, the impact plate 36 is driven to rotate, and the impact plate 36 can intermittently impact the drum 12, so that the drum 12 and the circular filter screen 13 in the drum 12 vibrate, thereby The debris stuck on the circular filter screen 13 is shaken off to prevent the debris from clogging the circular filter screen 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com