Corn starch process water protein recovery technique

A technology of corn starch and process water, applied in the preparation method of peptides, organic chemistry, peptides, etc., can solve the problems of poor effect and achieve good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

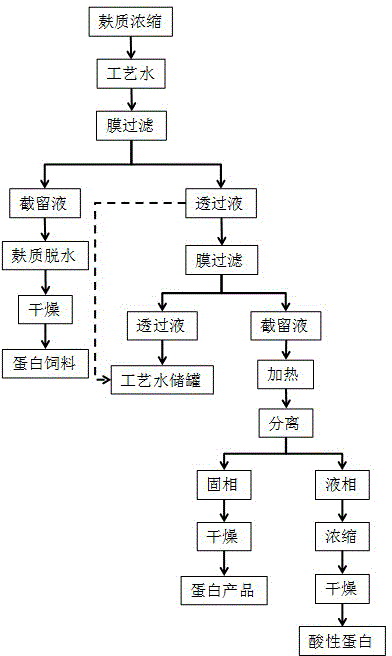

[0047] Present embodiment provides a kind of water protein recovery process of corn starch process, such as figure 1 shown, including the following steps:

[0048] 1) Take the overflow process water from the gluten concentrating centrifuge with a dry matter content of 1.1% and a pH value of 3.9, and use a tubular metal membrane with a pore size of 0.1 μm to concentrate and filter at 3 Bar at 50°C to obtain The first retentate and the first permeate; the first retentate is dehydrated and dried to obtain corn yellow powder;

[0049] 2) Use a roll-type organic membrane with a molecular weight cut-off of 10kDa and the membrane material is polyethersulfone, filter the first permeate obtained in the above step 1) at 4Bar and 45°C to obtain the second retentate and the second Permeate;

[0050] 3) Heat the second retentate in step 2) at 80°C for 18 minutes. At this time, a part of the soluble protein coagulates and precipitates after being heated (that is, the first protein product...

Embodiment 2

[0062] Present embodiment provides a kind of water protein recovery process of corn starch process, such as figure 1 shown, including the following steps:

[0063] 1) Take the overflow process water discharged from the gluten concentrating centrifuge with a dry matter content of 3.0% and a pH value of 4.2, and use a tubular ceramic membrane with a pore size of 1 μm to concentrate and filter at 2 Bar at 45 ° C to obtain the first A retentate and the first permeate; dehydrating and drying the first retentate to obtain corn yellow powder;

[0064] 2) Use a roll-type organic membrane with a molecular weight cut-off of 100kDa and the membrane material is polysulfone, and filter the first permeate obtained in the above step 1) at 4Bar and 35°C to obtain the second retentate and the second permeate. liquid;

[0065] 3) Heat the second retentate in step 2) at 120°C for 11s. At this time, a part of the soluble protein coagulates and precipitates after being heated (that is, t...

Embodiment 3

[0077] Present embodiment provides a kind of water protein recovery process of corn starch process, such as figure 1 shown, including the following steps:

[0078] 1) Take the overflow process water discharged from the gluten concentrating centrifuge with a dry matter content of 2.0% and a pH value of 3.8, and use a tubular ceramic membrane with a pore size of 0.5 μm to concentrate and filter at 2 Bar at 45 ° C to obtain The first retentate and the first permeate; the first retentate is dehydrated and dried to obtain corn yellow powder;

[0079] 2) Use a roll-type organic membrane with a molecular weight cut-off of 200kDa and the membrane material is polyvinylidene fluoride, filter the first permeate obtained in the above step 1) at 3.5Bar and 40°C to obtain the second retentate and second permeate;

[0080] 3) Heat the second retentate in step 2) at 75°C for 31 minutes, at this time, a part of the soluble protein coagulates and precipitates after being heated (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com