A kind of water protein recovery process of corn starch process

A technology of corn starch and process water, applied in the direction of peptide, organic chemistry, chemical instruments and methods, etc., can solve the problems of poor effect and achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

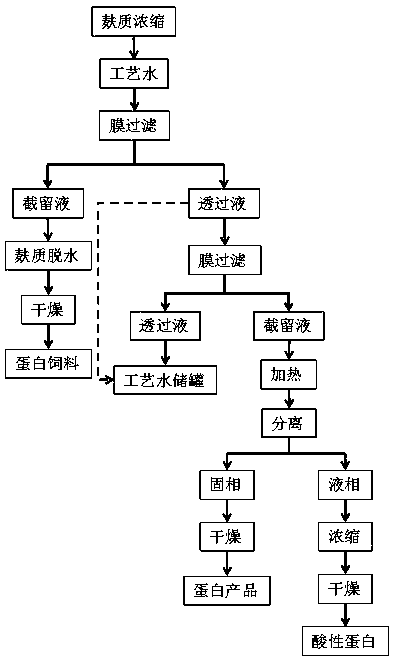

[0047] Present embodiment provides a kind of water protein recovery process of corn starch process, such as figure 1 shown, including the following steps:

[0048] 1) Take the overflow process water from the gluten concentrating centrifuge with a dry matter content of 1.1% and a pH value of 3.9, and use a tubular metal membrane with a pore size of 0.1 μm to concentrate and filter at 3 Bar at 50°C to obtain The first retentate and the first permeate; the first retentate is dehydrated and dried to obtain corn yellow powder;

[0049] 2) Use a roll-type organic membrane with a molecular weight cut-off of 10kDa and the membrane material is polyethersulfone, filter the first permeate obtained in the above step 1) at 4Bar and 45°C to obtain the second retentate and the second Permeate;

[0050] 3) Heat the second retentate in step 2) at 80°C for 18 minutes. At this time, a part of the soluble protein coagulates and precipitates after being heated (that is, the first protein product...

Embodiment 2

[0062] Present embodiment provides a kind of water protein recovery process of corn starch process, such as figure 1 shown, including the following steps:

[0063] 1) Take the overflow process water discharged from the gluten concentrating centrifuge with a dry matter content of 3.0% and a pH value of 4.2, and use a tubular ceramic membrane with a pore size of 1 μm to concentrate and filter at 2 Bar at 45 ° C to obtain the first A retentate and the first permeate; dehydrating and drying the first retentate to obtain corn yellow powder;

[0064] 2) Use a roll-type organic membrane with a molecular weight cut-off of 100kDa and the membrane material is polysulfone, and filter the first permeate obtained in the above step 1) at 4Bar and 35°C to obtain the second retentate and the second permeate. liquid;

[0065] 3) Heat the second retentate in step 2) at 120°C for 11s. At this time, a part of the soluble protein coagulates and precipitates after being heated (that is, the first...

Embodiment 3

[0077] Present embodiment provides a kind of water protein recovery process of corn starch process, such as figure 1 shown, including the following steps:

[0078] 1) Take the overflow process water discharged from the gluten concentrating centrifuge with a dry matter content of 2.0% and a pH value of 3.8, and use a tubular ceramic membrane with a pore size of 0.5 μm to concentrate and filter at 2 Bar at 45 ° C to obtain The first retentate and the first permeate; the first retentate is dehydrated and dried to obtain corn yellow powder;

[0079] 2) Use a roll-type organic membrane with a molecular weight cut-off of 200kDa and the membrane material is polyvinylidene fluoride, filter the first permeate obtained in the above step 1) at 3.5Bar and 40°C to obtain the second retentate and second permeate;

[0080] 3) Heat the second retentate in step 2) at 75°C for 31 minutes, at this time, a part of the soluble protein coagulates and precipitates after being heated (that is, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com