Pivoting type gearbox

A gearbox and pivot technology, which is applied in the field of pivot gearboxes, can solve problems such as heat generation of pivot gearbox components, complex movement of pivot gearboxes, and insufficient bridge rigidity, so as to reduce heat damage, Strong ability to transmit torque and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

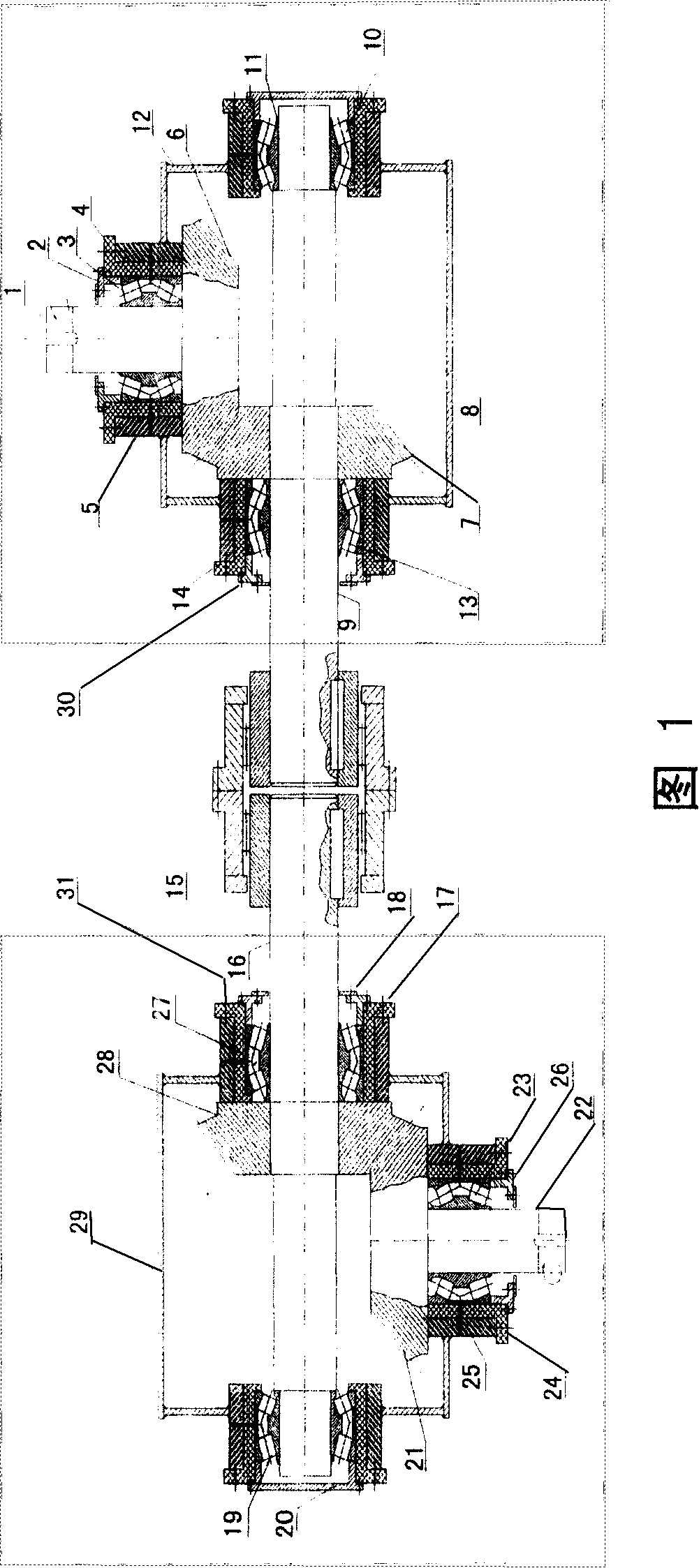

[0016] As shown in Figure 1, the present invention comprises: the box body 30 that contains input shaft, the box body 31 that contains output shaft and gear coupling 15, described box body 30 that contains input shaft includes: input shaft 1, the first A chuck 2, input shaft bearing 3, first bearing seat 4, first steel shell 5, first bevel gear 6, second bevel gear 7, first shaft 8, second shaft 9, first bearing 10, card Spring 11, the first gear case case 12, the second bearing 13 and the second bearing seat 14, the input shaft 1 is supported by the input shaft bearing 3 outside it, the first chuck 2 is fixedly connected with the first bearing seat 4 by bolts , the first bearing seat 4 is connected with the first steel shell 5 outside by bolts, the first bevel gear 6 at the top of the input shaft 1 is set in the first gearbox case shell 12, and the second bevel gear 7 is set in the second At the top of the shaft 9, the first shaft 8 is supported by the first bearing 10 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com