Steel-concrete lapping type combination beam

A technology of concrete and composite beams, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems affecting the stress state and service life of composite beams, long construction period, complex structure, etc., to improve the stress state and service performance, improve Construction efficiency, the effect of simplifying the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

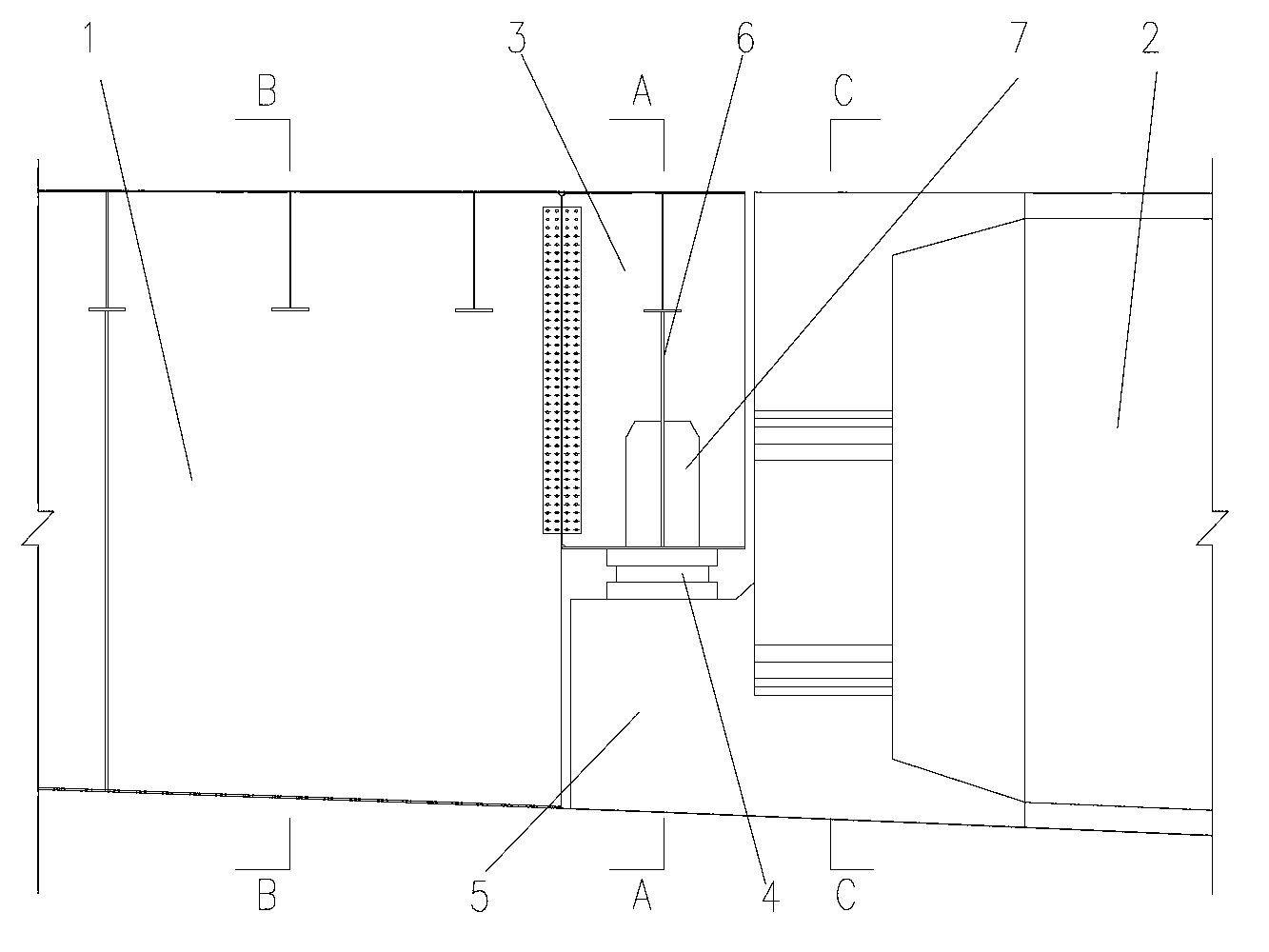

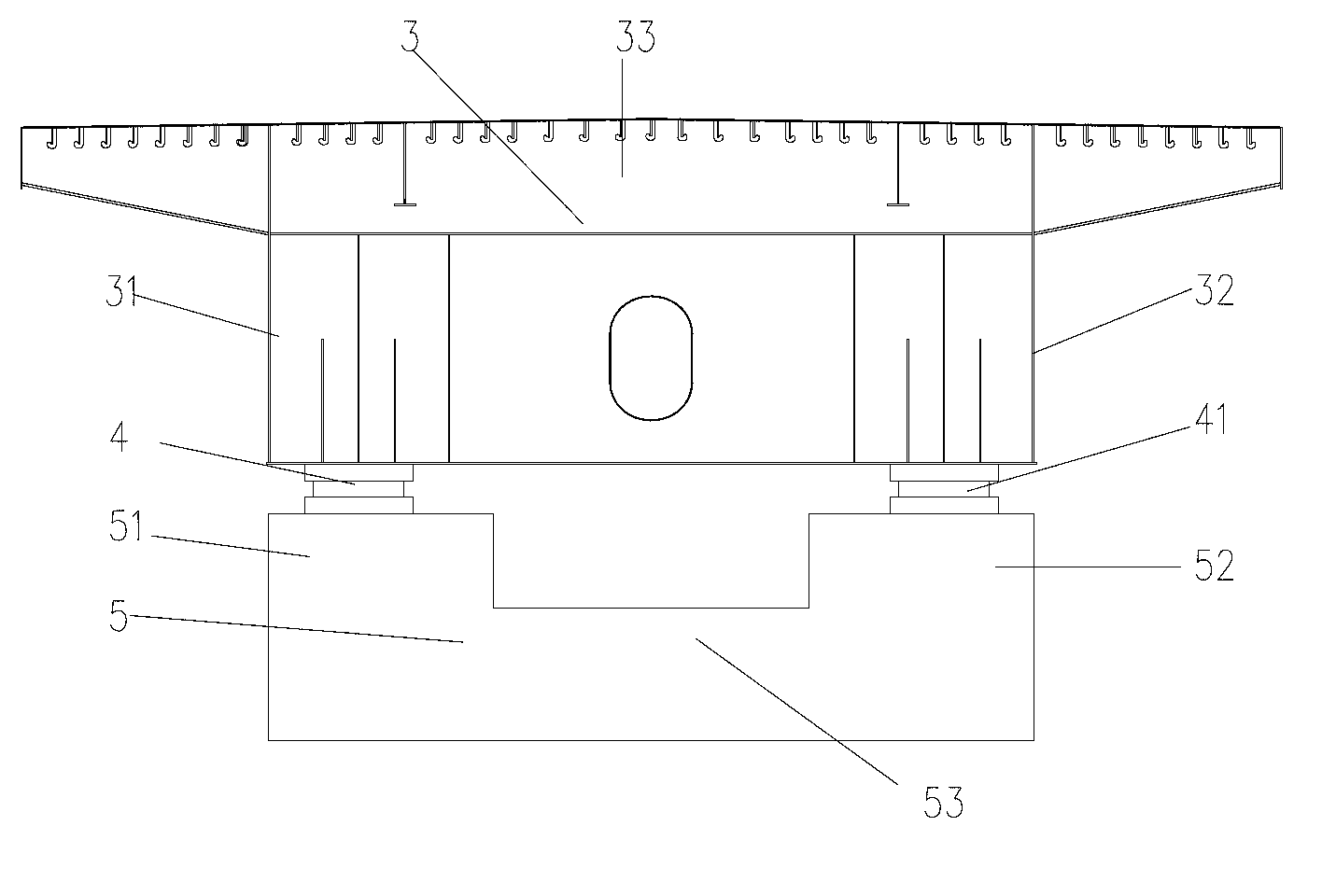

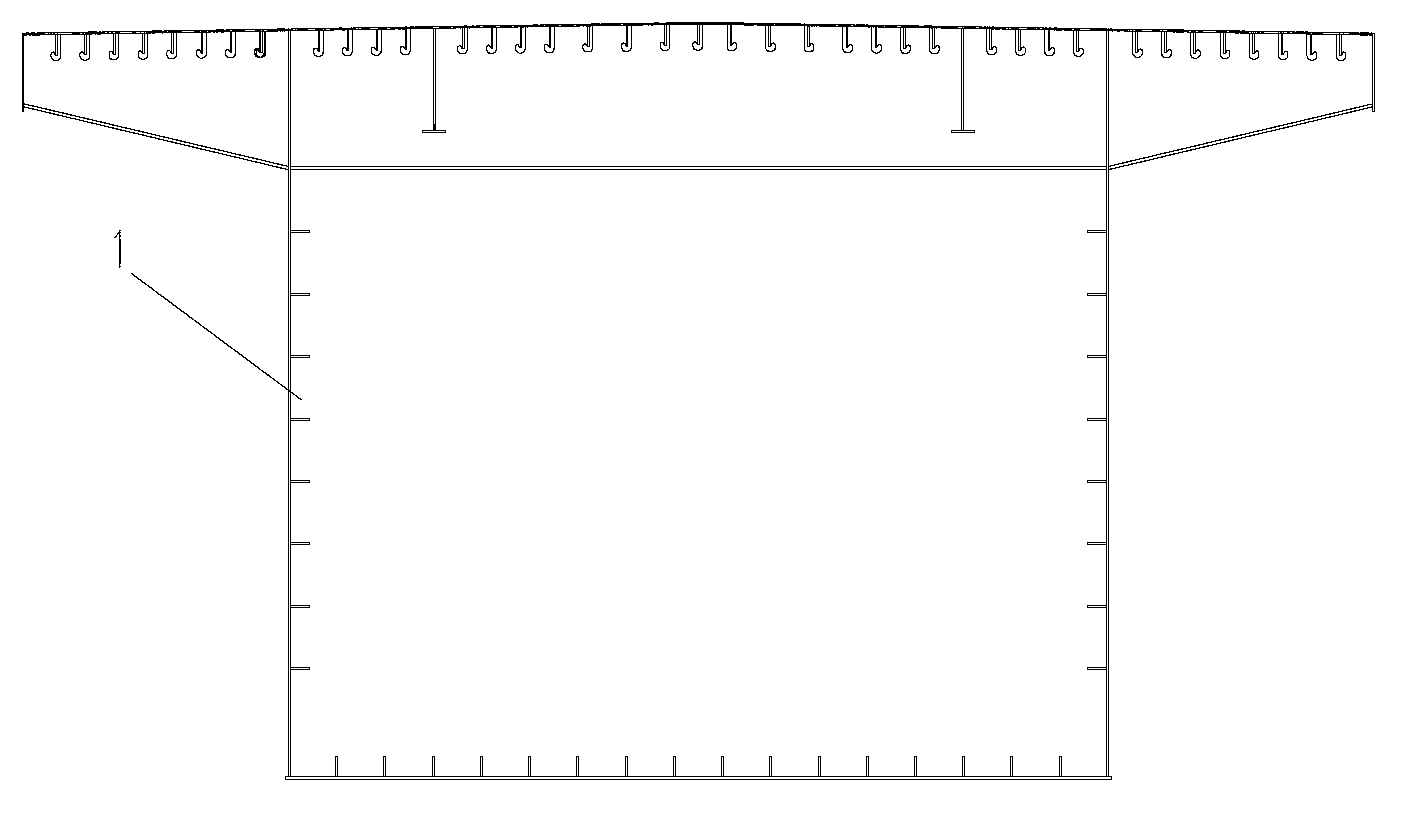

[0018] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the structure of A-A of the present invention; image 3 It is a schematic diagram of the B-B structure of the present invention; Figure 4 It is a schematic diagram of the C-C structure of the present invention; as shown in the figure: a steel-concrete lap composite beam of the present embodiment includes a steel box girder section 1 and a concrete beam section 2 positioned at both ends of the steel box girder section 1. The two ends of the steel box girder section 1 are overlapped with the concrete beam section 2; the overlapping connection structure produces a performance similar to a hinge, so that the freedom of longitudinal rotation between the steel beam section and the concrete beam section can be achieved.

[0019] In this embodiment, the concrete girder section 2 and the steel box girder section 1 form a notch overlapping structure; the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com