Method for intercepting, extracting and releasing pressure gas by blasting anti-reflection directional long drill hole of thick and hard roof rock stratum

A thick and hard roof and long drilling technology, which is applied in gas discharge, earthwork drilling, mining equipment, etc., can solve problems such as increased stress, high gas concentration, and threats to the safety of the working face, so as to reduce additional load and improve gas pumping. Production volume and drainage rate, and the effect of improving the gas drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] 1. Overview of the experimental work surface

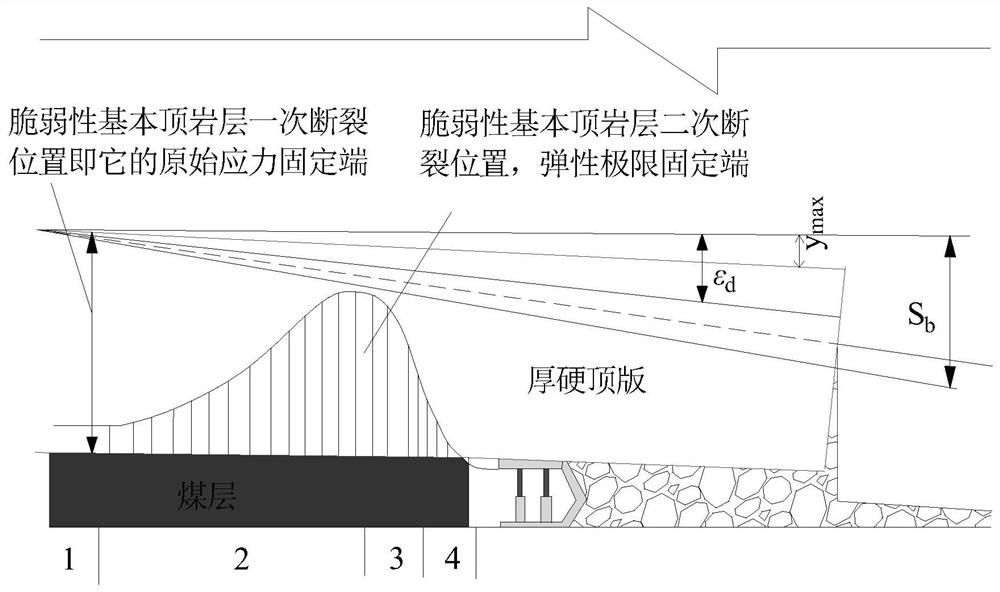

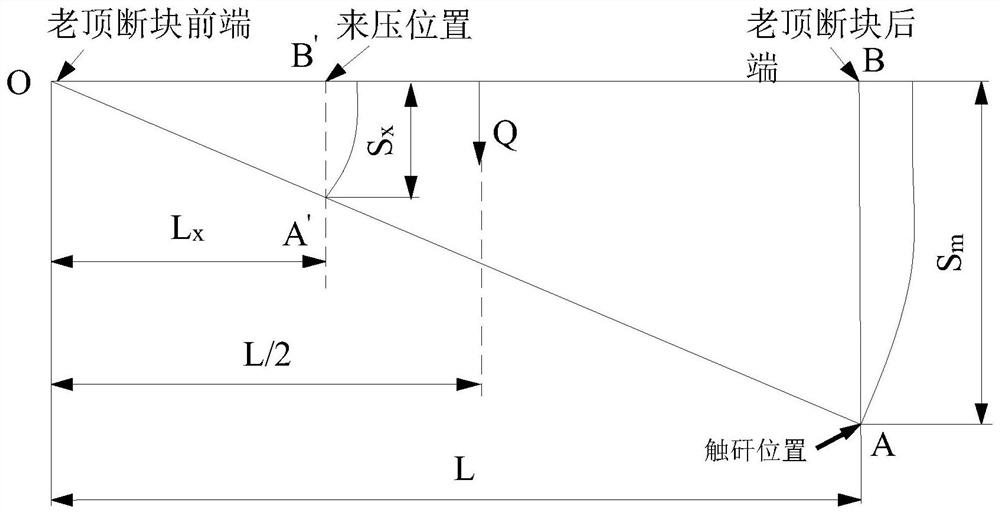

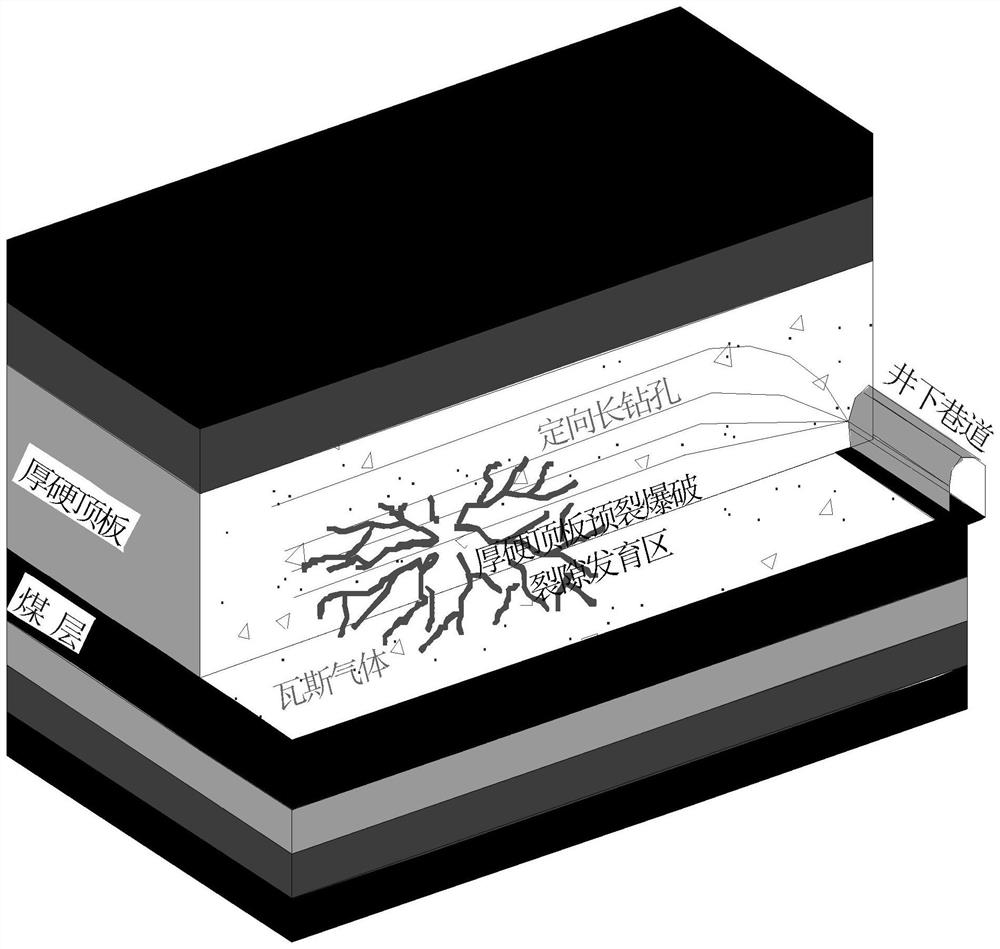

[0055] like Figure 4 As shown, Qidong Coal Mine is a coal and gas outburst mine, and the main coal mining seams are all outburst coal seams. 8 2 31 working face is the third mining area 8 2 The working face of the first coal mining protected layer is laid out in a direction with a length of 1100m, "U" type ventilation, a single direction and long wall retreating comprehensive mechanized coal mining, 8 2 The histogram of the 31 working face is as follows image 3 shown. 8 2 31 The top of the working face is the upper protective layer 7 1 In the coal mined-out area, the normal distance is about 30-33m; the roof of the working face is sandstone, the firmness coefficient is 13, and the thickness is 24.65-31.88m. It is a very thick sandstone roof and is not easy to collapse. The caving zone of the hard sandstone roof is not obvious after mining. The hard roof forms a large area of overhang after the coal seam is mined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com