Hot forging die of gear and surface high-temperature self-lubricating treatment method thereof

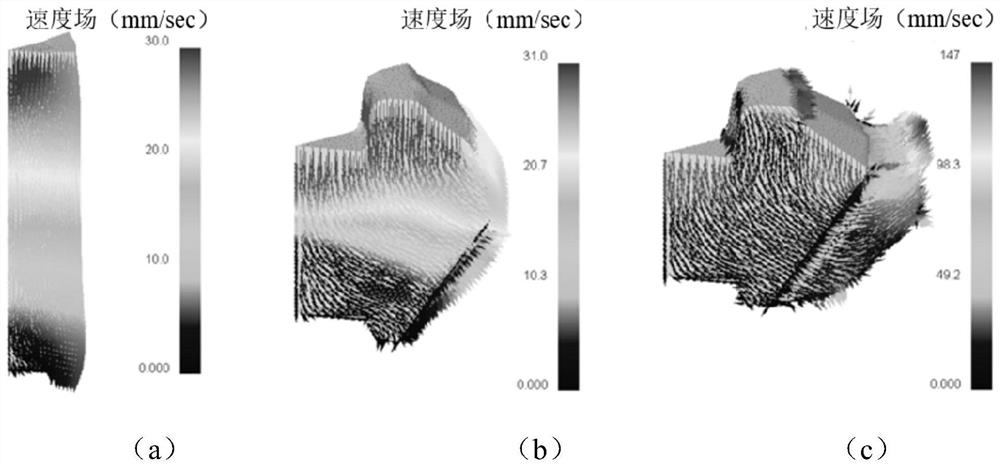

A high-temperature self-lubricating, hot forging die technology, used in lubricating compositions, manufacturing tools, forging/pressing/hammer devices, etc. Metal flow speed, uneven metal flow and other problems, to achieve the effect of improving mold life, improving metal flow uniformity, improving mechanical properties and friction and lubrication properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

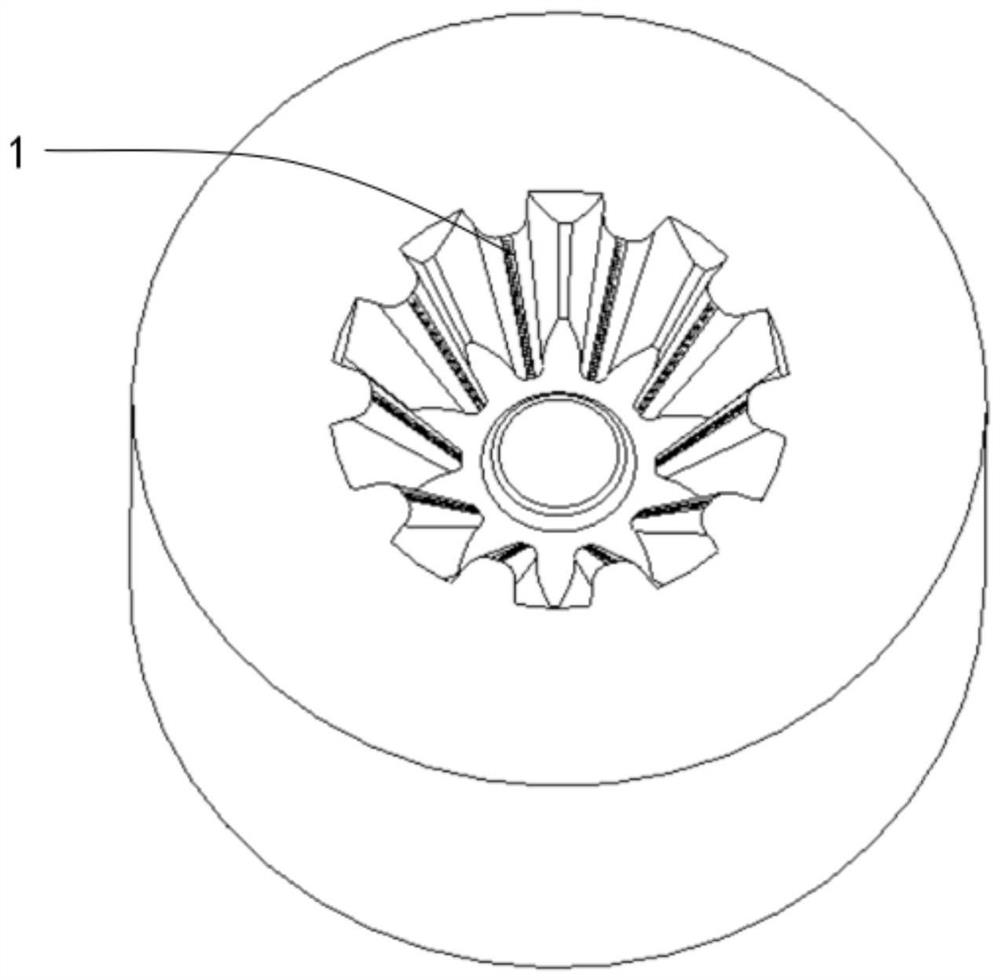

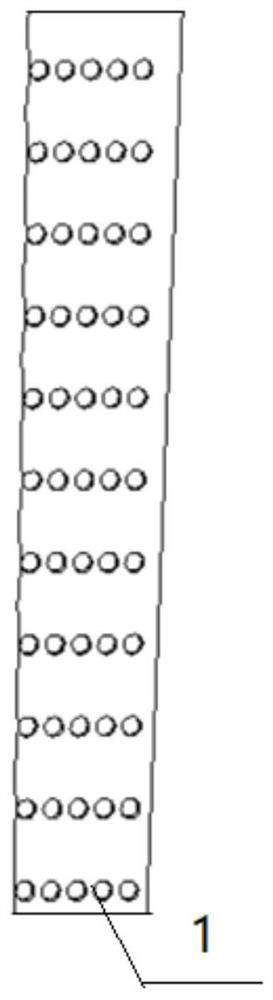

[0023] like figure 1 , 2 , 3 and 4, a high-temperature self-lubricating treatment method for a gear hot forging die surface, comprising the following steps: processing the micro-pit texture in the non-meshing affected area of the tooth-shaped concave die 2 tooth top area of the gear hot forging die, and micro-pit texture The pit texture is circular micro-pits 1 arranged in an array, and then an ultrasonic cleaning machine is used to remove impurities retained after processing, and then a high-temperature-resistant coating 3 is prepared on the surface of the tooth-shaped die with a micro-pits texture, On the coating 3, a layer of heat-insulating composite lubricant 4 is applied. combine figure 1 and figure 2 On the surface of the non-meshing affected area of the tooth-shaped concave die 2 of the gear hot forging die, a five-axis horizontal machining center is used to process the micro-pit 1, such as image 3 As shown, after using an ultrasonic cleaning machine to rem...

Embodiment 2

[0034] A gear hot forging die is prepared according to the high-temperature self-lubricating treatment method for the surface of the gear hot forging die described in Embodiment 1. Therefore, it has the beneficial effects described in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com