External contour air bearing

An air bearing and outer profile technology, which is applied in the field of bearings, can solve problems such as unfavorable speed increase and large quality, and achieve the effect of shortening length and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

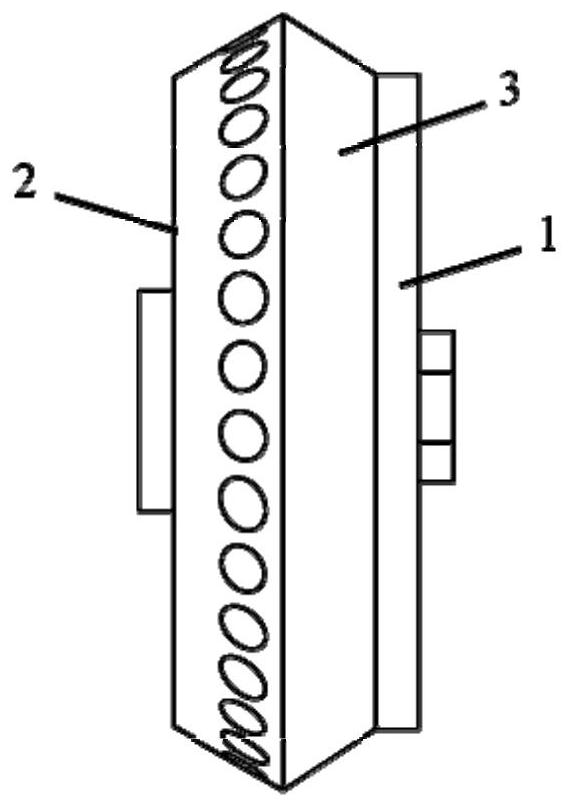

[0020] The present invention provides an outer profile air bearing, comprising an outer profile air bearing, the outer profile air bearing is applied to a closed type rotary fluid machine, and the outer surface of the working wheel cover of the closed type fluid machine is designed as a wheel cover The combination of the outer cylindrical surface 1 and the outer conical surface 3 of the wheel cover, such as figure 1 shown.

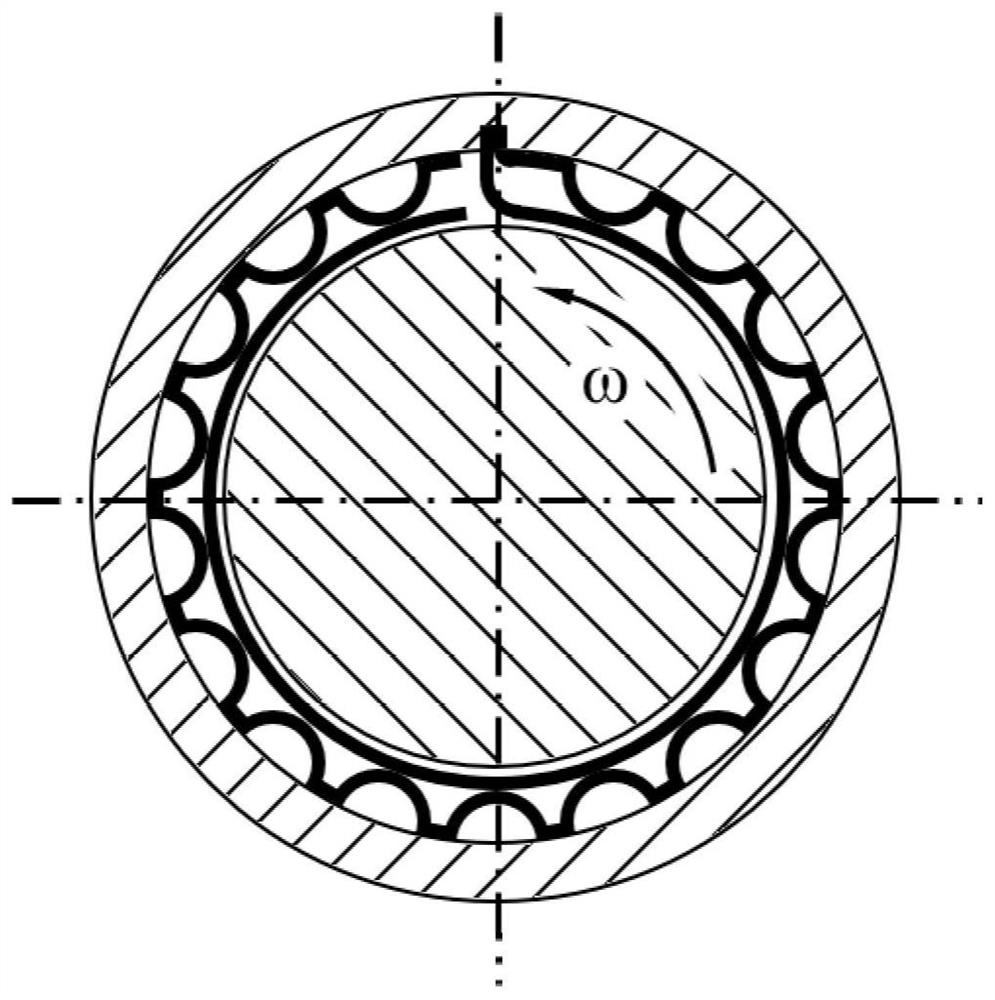

[0021] Further, when the outer contour air bearing is used as the outer contour radial air bearing 10, when the outer contour air bearing is used as the outer contour radial air bearing, it is installed on the outer cylinder of the wheel cover of the closed working wheel Face 1, the closed working wheel adopts turbine and / or compressor wheel.

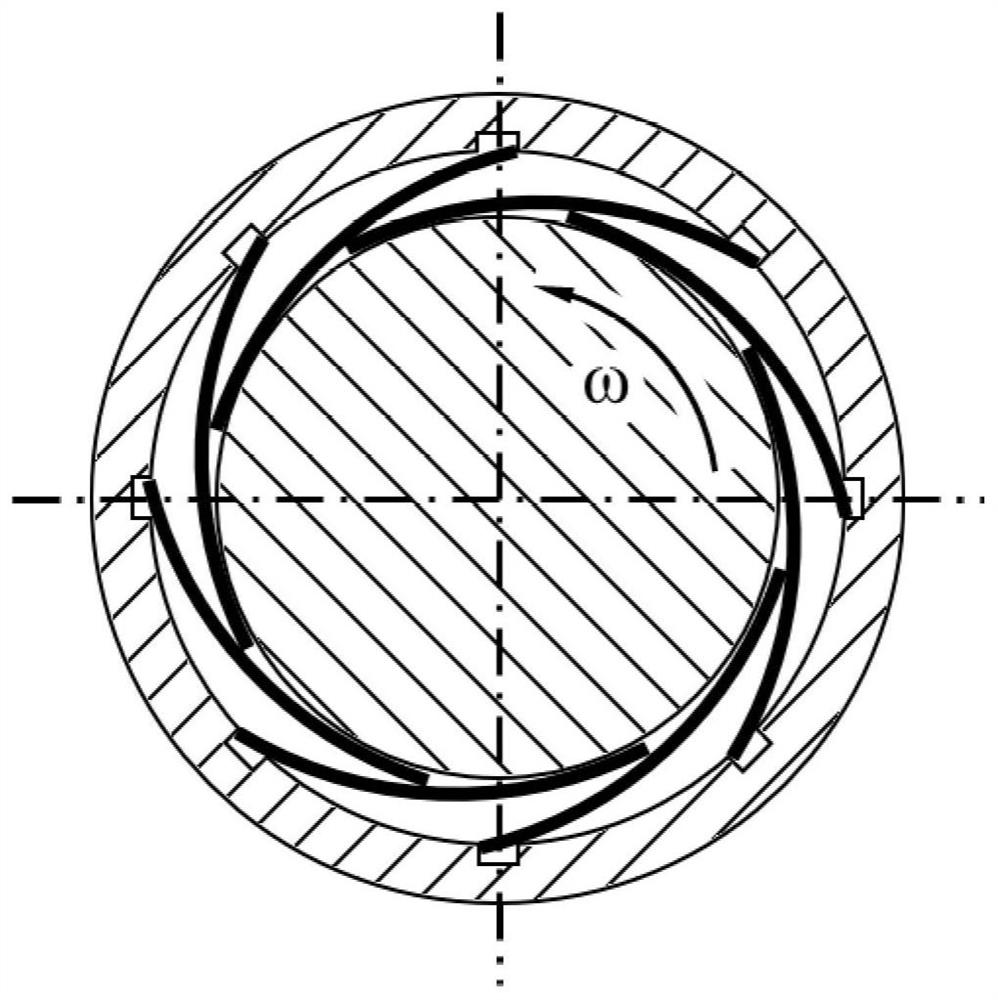

[0022] Further, when the outer profile air bearing is used as the outer profile thrust air bearing 11, it can be installed on the back side of the turbine wheel 2 or the outer conical surface 3 of the compressor wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com