Multi-stage compressor, air conditioner system and control method of multi-stage compressor

A technology for compressor and gas control, which is applied in the control of multi-stage compressors, multi-stage compressors and air conditioning systems, and can solve the problems of narrow working condition adaptation range, reduced energy efficiency, and poor adaptability to operating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

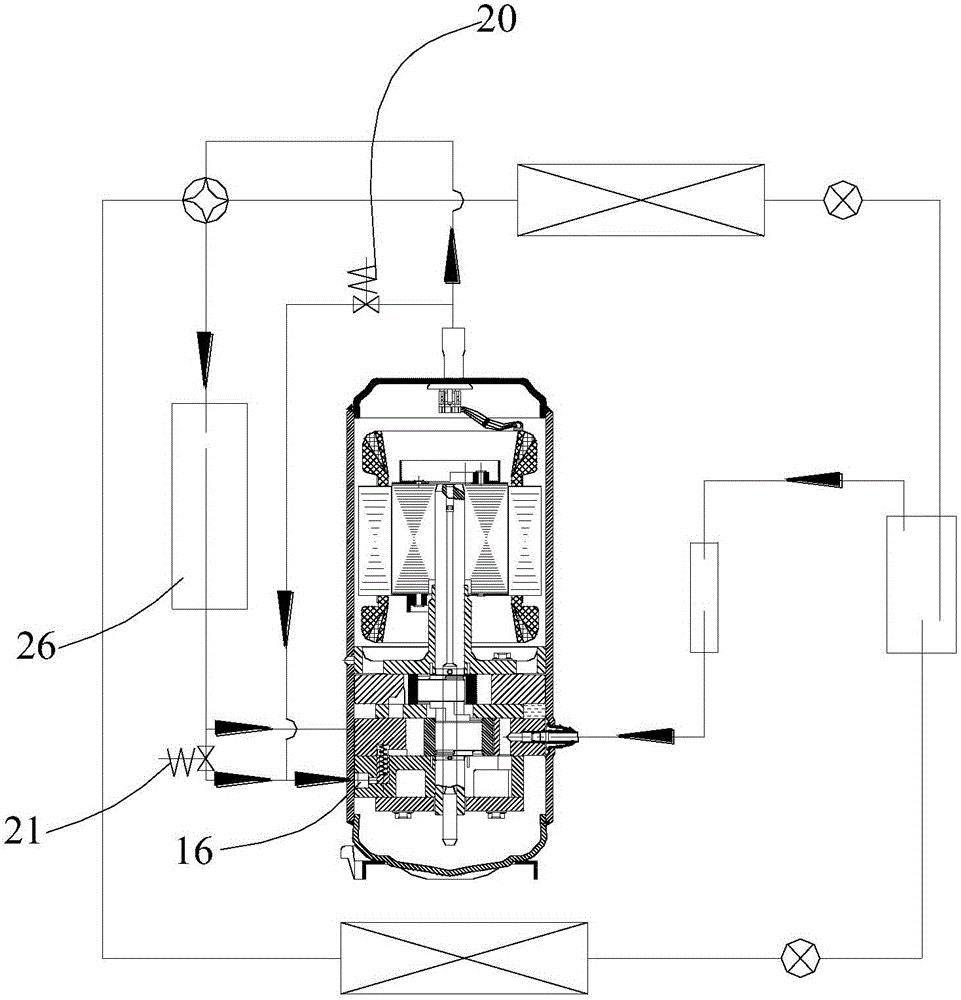

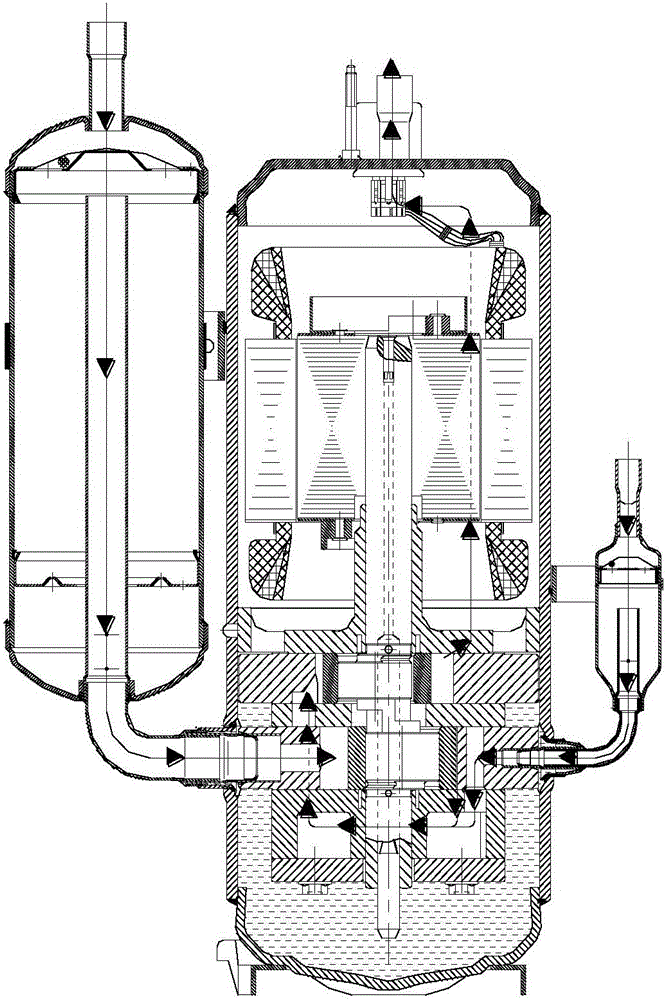

[0061] Embodiment 2 Compressor variable capacity principle: the variable capacity control mode of the compressor is realized by controlling the pressure switching of the plug head (see Figure 8 ). When the first solenoid valve 20 is turned on and the second solenoid valve 21 is closed, high pressure is introduced into the head of the plug, and there is a certain pressure difference between the head of the plug and the tail of the plug, and the force generated by the pressure difference will overcome the elastic force of the spring to push the plug Moving toward the tail, at this time the cylinder bypass return flow channel 12 is blocked, and the gas in the cylinder suction cavity will not be able to flow back to the suction port 13, thereby realizing the two-stage operation mode of the multi-stage compressor with large displacement and small volume ratio (see Figure 8 , Figure 13-1 ). When the first solenoid valve 20 is closed and the second solenoid valve 21 is turned on...

Embodiment 3

[0063] Embodiment Three The low-pressure stage cylinder 14 is provided with a bypass hole, an intermediate flow channel, and an enthalpy-increasing port 24 (see Figure 15 ), the bypass port 11 is connected with the control valve 25 and the external pipeline to form a bypass return channel 12, and the gas in the suction chamber of the low-pressure stage cylinder 14 can communicate with the suction line through the bypass return channel 12 (see Figure 14 ). Other parts and structural composition are similar to the first embodiment.

[0064] The variable capacity control mode of the compressor in the third embodiment is realized by controlling the closing and conducting of the control valve 25 (see Figure 14 ). When the control valve 25 is closed and the bypass return passage is blocked, the gas in the suction chamber of the cylinder will not be able to flow back to the suction pipeline, thereby realizing the two-stage operation mode of the multi-stage compressor with large ...

Embodiment 5

[0067] Embodiment 5 Compressor variable capacity principle: the variable capacity control mode of the compressor is realized by controlling the pressure switch of the plug head (see Figure 17 ). When the first solenoid valve 20 is turned on and the second solenoid valve 21 is closed, the head of the plug is introduced with medium pressure, and there is a certain pressure difference between the head of the plug and the tail of the plug, and the force generated by the pressure difference will overcome the elastic force of the spring to push the plug The pin moves in the direction of the tail. At this time, the bypass return channel 12 of the cylinder is blocked, and the gas in the suction chamber of the cylinder will not be able to flow back to the suction port 13, thereby realizing the two-stage operation mode of the multi-stage compressor with large displacement and small volume ratio. (See Figure 17 , Figure 13-1 ). When the first solenoid valve 20 is closed and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com