A shock absorbing device for a multi-wire cutting machine

A multi-wire cutting machine and shock absorbing device technology, which is applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of inability to combine shock absorbing supports with metal wires, inability to choose freely, and inconvenient control and adjustment. To achieve a good combined shock absorption support effect, flexible and convenient use and control, and to improve the combined shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

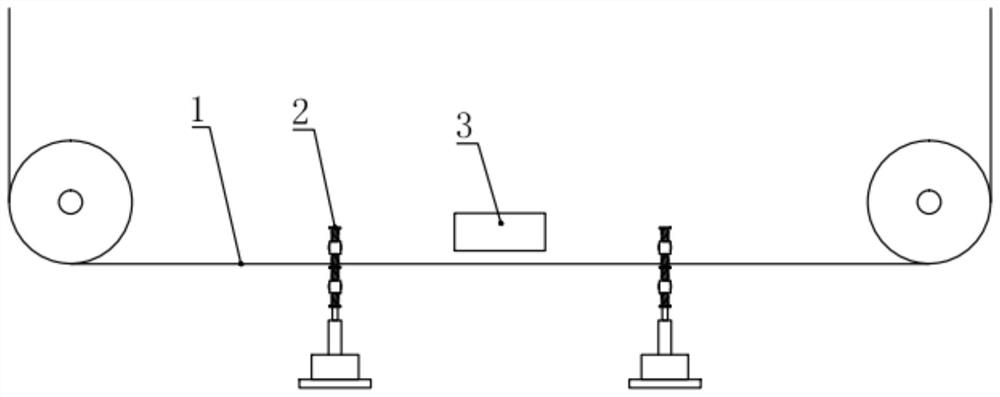

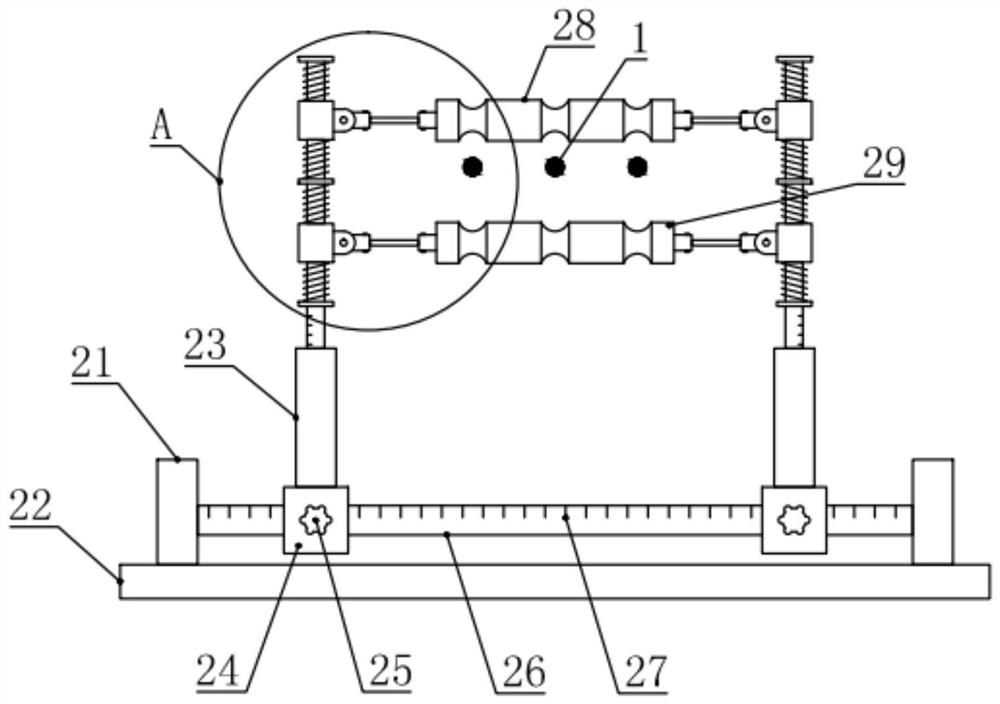

[0026] see Figure 1-2 , 5-6, in the embodiment of the present invention, a multi-wire cutting machine damping device includes two symmetrically placed shock-absorbing assemblies 2, and the wire 1 of the multi-wire cutting machine passes through the two shock-absorbing assemblies 2 There is also a feed table 3 that cooperates with the metal wire 1 between the two shock absorbing assemblies 2; Rod 26, upper support roller 28, lower support roller 29 and horizontal and vertical elastic support components, a side support plate 21 is respectively installed and fixed on the front and rear sides of the top of the bottom plate seat 22, and a side support plate 21 is installed between the two side support plates 21. An installation cross bar 26 is fixed, and the installation cross bar 26 is provided with a scale 27, and two sliding sleeves 24 are provided for cooperating and sliding on the installation cross bar 26, and the sides of the two described sliding sleeves 24 are provided wi...

Embodiment 2

[0028] see Figure 2-6 , the difference between this embodiment and embodiment 1 is:

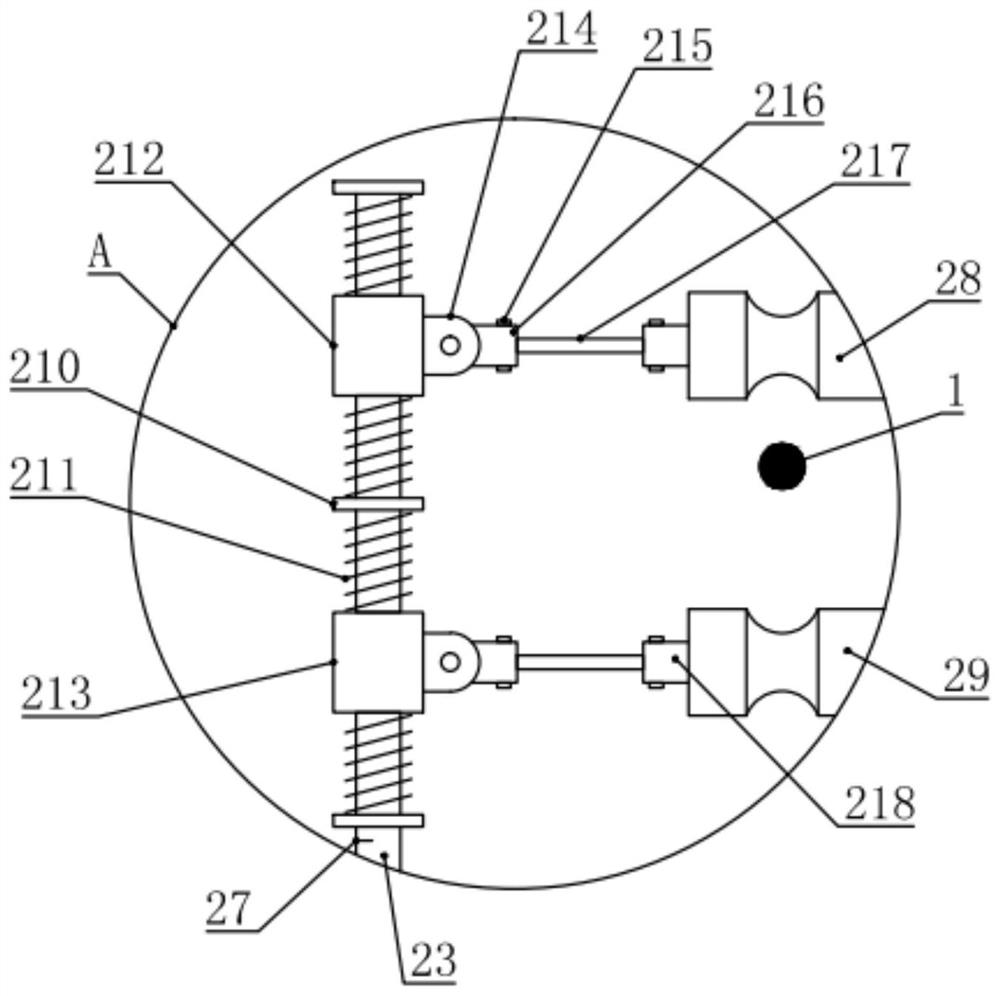

[0029] In this embodiment, the horizontal and vertical elastic support components include a limiting ring plate 210, a shock absorbing spring 211, an upper collar 212, a lower collar 213, a hinge support 214, a first connecting shaft 216, an elastic cord 217 and a second Two connecting shafts 218, the telescopic rod of the telescopic cylinder 23 is also provided with a scale 27, and the telescopic rod of the telescopic cylinder 23 is respectively fitted with an upper collar 212 and a lower collar 213 for sliding, and the upper collar 212 On the telescopic cylinder 23 telescopic rod on the upper side, on the telescopic cylinder 23 telescopic rod on the lower side of the collar 213 and on the telescopic cylinder 23 telescopic rod between the upper collar 212 and the lower collar 213, a limit ring is fixed respectively plate 210, the upper and lower sides of the upper collar 212 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com