Planet gear bearing forced lubricating device

A technology of forced lubrication and planetary gear, which is applied in the direction of gear lubrication/cooling, transmission parts, belt/chain/gear, etc., can solve the problems of poor adjustment of oil supply, need for sealing links, and difficult processing, etc., to achieve zero Fewer parts, reduced processing difficulty, and good adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

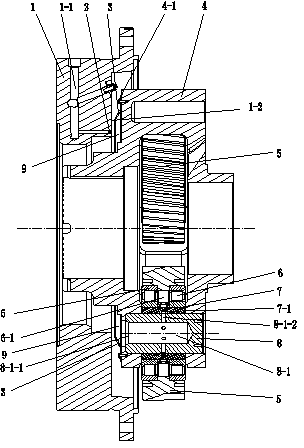

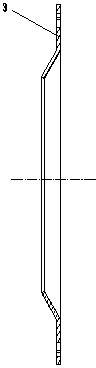

[0014] Such as figure 1 , 2 As shown, a forced lubrication device for planetary wheel bearings includes a box body 1, a planetary carrier 4, a planetary gear 5, a bearing 6 and a planetary pin 8, the planetary carrier 4 is rotatably supported on the box body 1, and the planetary pin 8 is mounted on the planetary carrier 4, the planetary gear 5 is rotatably supported on the planet carrier 4 through the bearing 6, and the inner surface 4-1 of the planet carrier 4 opposite to the inner surface 1-2 of the box body 1 has an annular protrusion 3, the A centrifugal oil collection chamber 9 is formed between the inner surface 4-1 of the planetary carrier 4 and the inner wall of the annular protrusion 3. The box body 1 has an oil injection channel 1-1 and is provided with a nozzle 2. The oil injection channel 1-1 and the The nozzles 2 communicate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com