Plug-in electric rotary tiller

A rotary tiller and plug-in technology, which is applied in the field of plug-in electric rotary tillers, can solve problems such as difficulty in realizing stepless speed regulation, poor operation continuity, and complicated operation process, achieving less cost increase and high feasibility , good cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

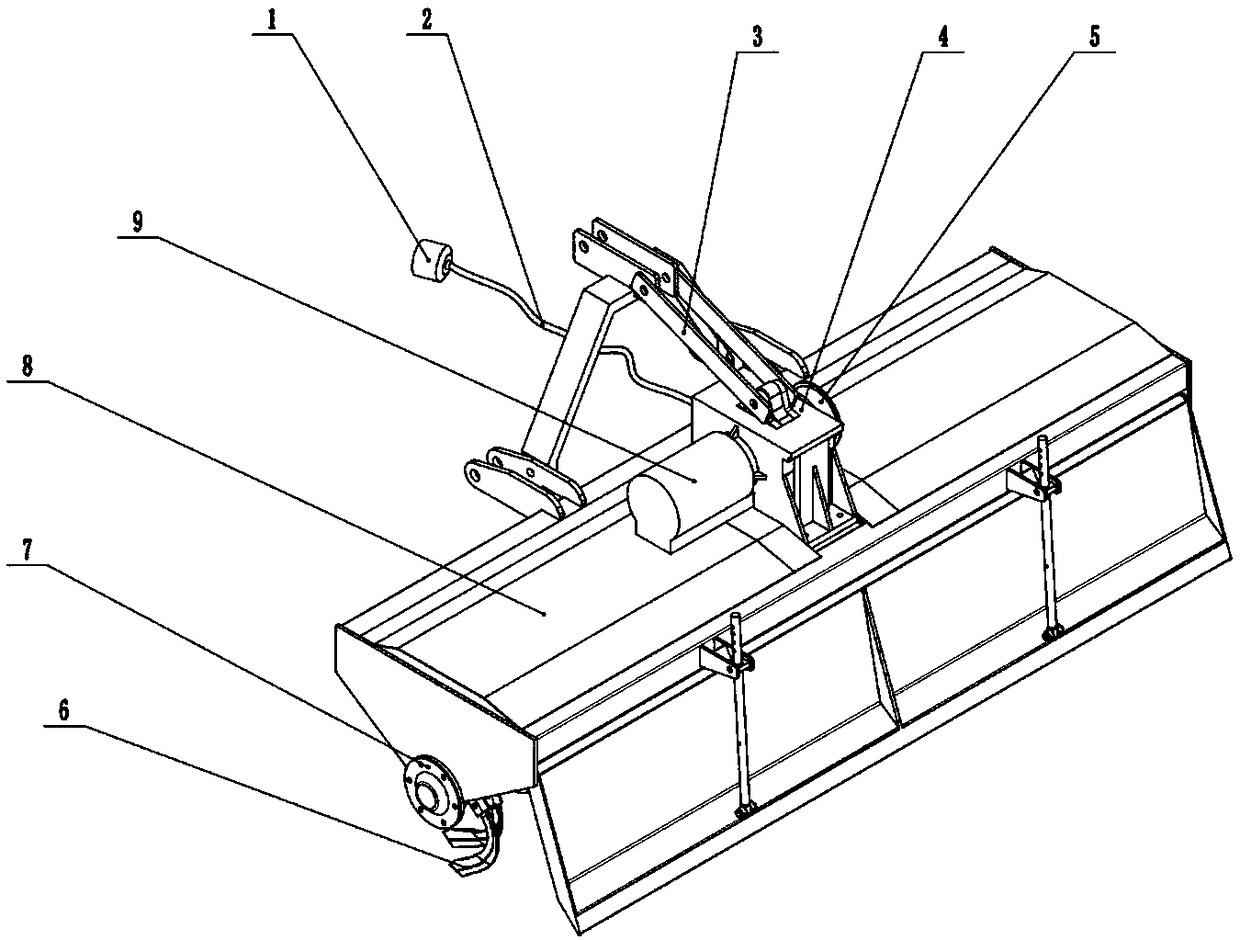

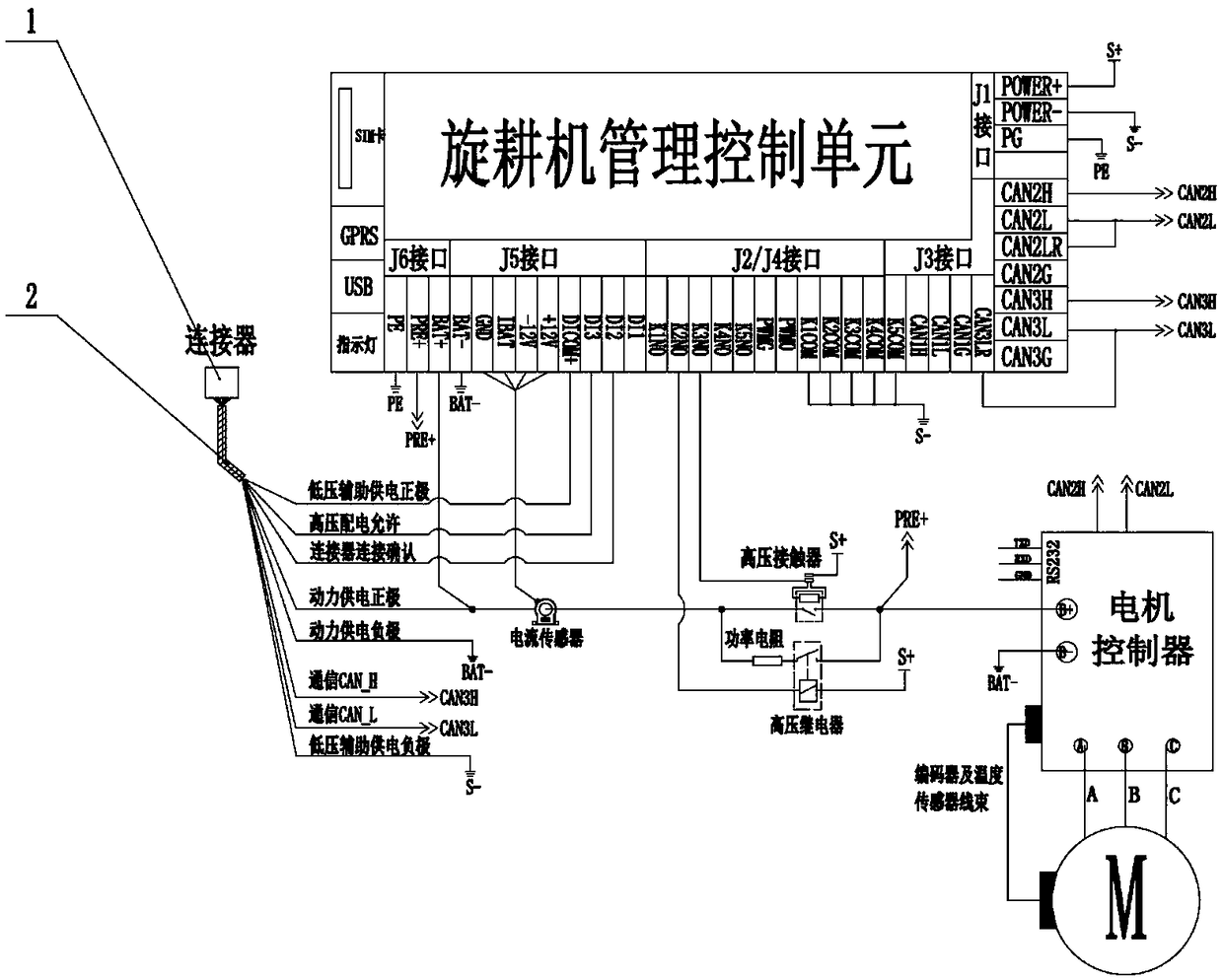

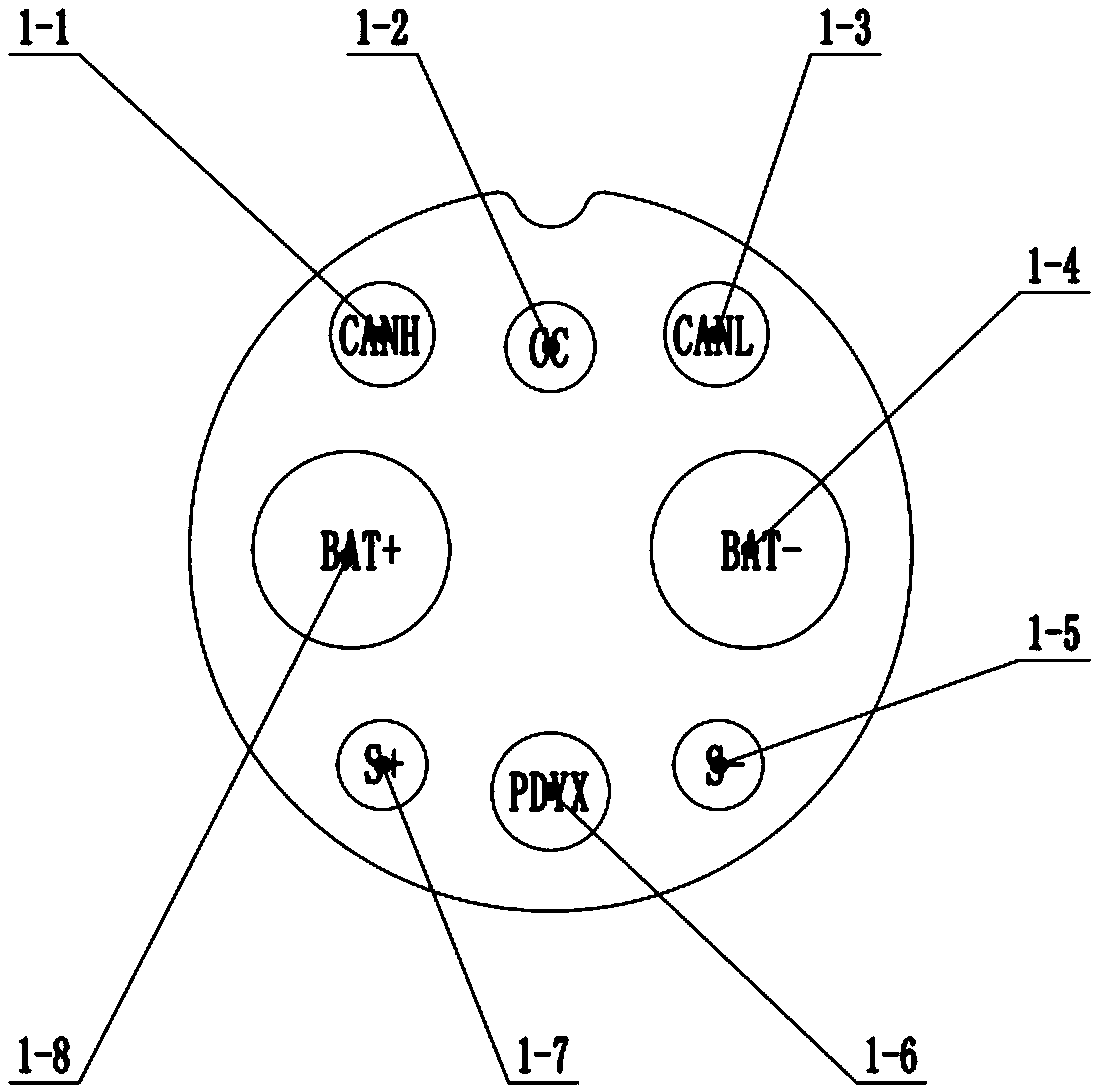

[0046] Based on the above analysis, the present invention discloses a plug-in electric rotary tiller, which combines figure 1 , its overall structure includes multi-contact electrical connector 1, power transmission cable 2, suspension rod 3, reducer assembly 4, electric control box 5, rotary cultivator roller cutter 6, roller cutter shaft assembly 7, rotary The cultivator body 8 and the motor drive device 9, the multi-contact electrical connector 1 can be respectively provided with one or more according to the voltage level and functional attributes; the multi-contact electrical connector 1 is connected to the power transmission One end of the cable 2; the power transmission cable 2 is a multi-core cable, and the number of effective cores of the power transmission cable 2 corresponds to the number of contacts of the multi-contact electrical connector 1; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com