Temperature forecasting method for finish rolling inlet during hot continuous rolling

A technology of finish rolling entrance temperature and hot continuous rolling, which is applied in metal rolling, metal rolling, length measuring devices, etc., can solve the problems of different convective heat transfer coefficients, difficult to achieve temperature measurement, errors, etc., and achieve improved forecasting The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

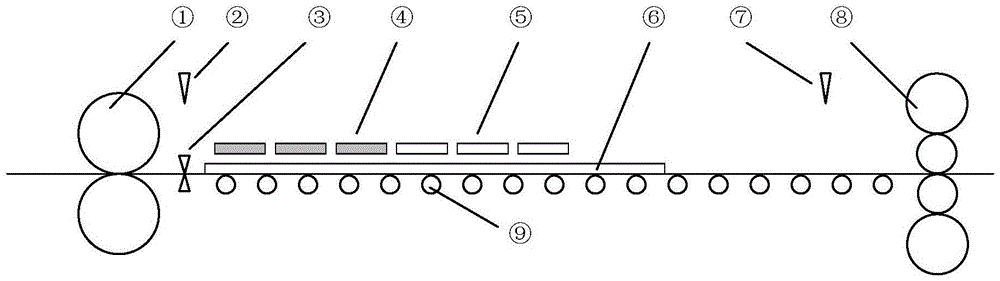

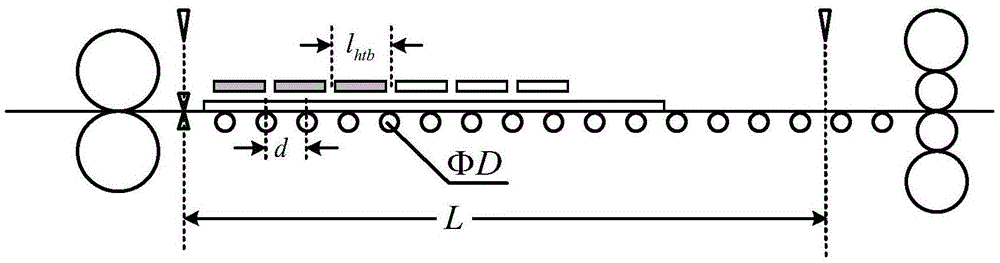

[0025] In this embodiment, the hot rolling field equipment layout is as follows figure 1 Shown: After the rolled piece ⑥ passes through the end stand ① of the roughing mill, it enters the intermediate conveying roller table (there are several roller table rollers ⑨ on the intermediate conveying roller table). ③, through the heat preservation cover (the heat preservation cover ④ put into use and the heat preservation cover ⑤ not put into use), it reaches the finish rolling entrance thermometer ⑦, and finally enters the first finish rolling stand ⑧, and starts the rolling process in the finish rolling area.

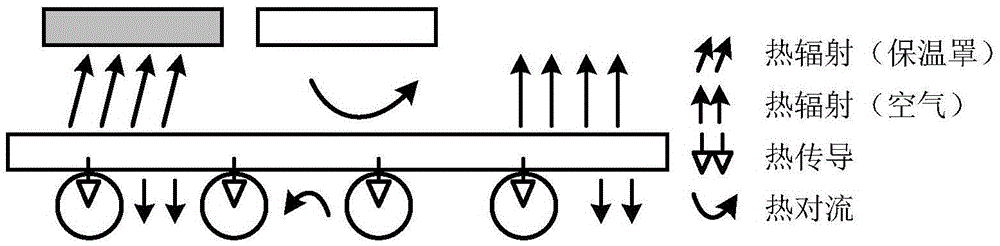

[0026] The heat transfer mode of the rolling stock in the hot continuous rolling process is as follows: image 3 As shown, during the operation of the rolled piece in the intermediate transport roller table, the heat transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com