Temperature rise test and measurement system and method for split heat dissipation transformer

A temperature rise test and measurement system technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of small number of inlet and outlet pipelines, short running time of hanging network, lack of experience data, etc., and achieves high accuracy, Easy to operate, reasonable test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

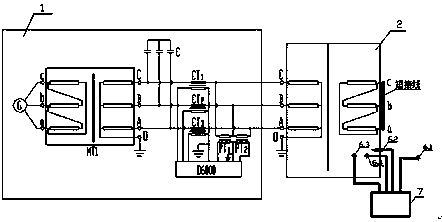

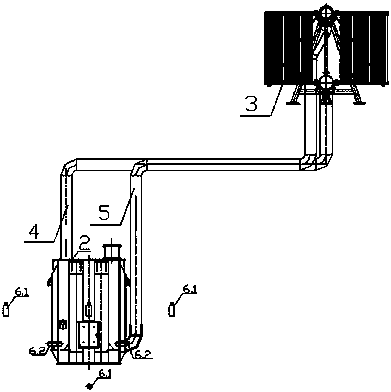

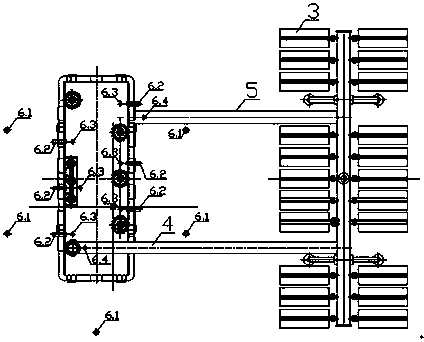

[0022] The following combination Figure 1 ~ Figure 3 , the technical content, structural features, achieved goals and effects of the present invention will be described in detail through preferred embodiments.

[0023] Such as figure 1 , figure 2 with image 3 As shown, the temperature rise test and measurement system of the split heat dissipation transformer provided by the present invention includes: a test power supply and a metering system 1, which are connected with an underground transformer 2 (one of the split heat dissipation transformers) through a circuit; radiator group 3 , and the input and output ports of the underground transformer 2 are connected through pipelines; multiple sets of temperature sensors, the first set of temperature sensors are distributed on the top of the underground transformer 2, the second set of temperature sensors are distributed on the bottom of the underground transformer 2, and the third set The temperature sensors are distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com