Method for carrying out early warning of abnormal superheated steam temperature and fault diagnosis on direct current megawatt unit

A superheated steam temperature and fault diagnosis technology, applied in electrical testing/monitoring, etc., can solve problems such as early warning of abnormal superheated steam temperature, large fluctuations in final steam temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

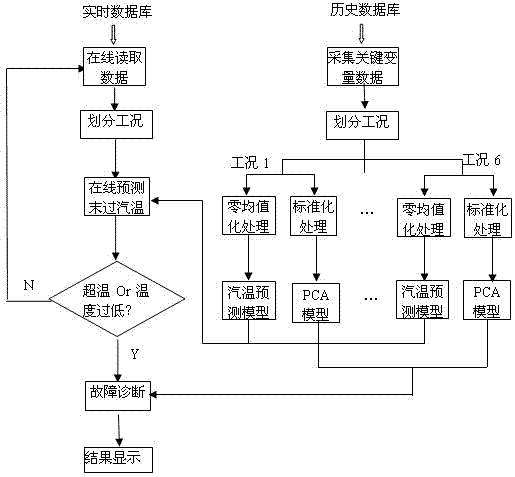

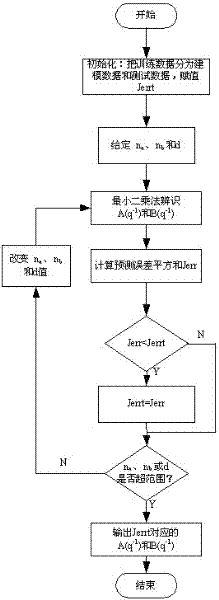

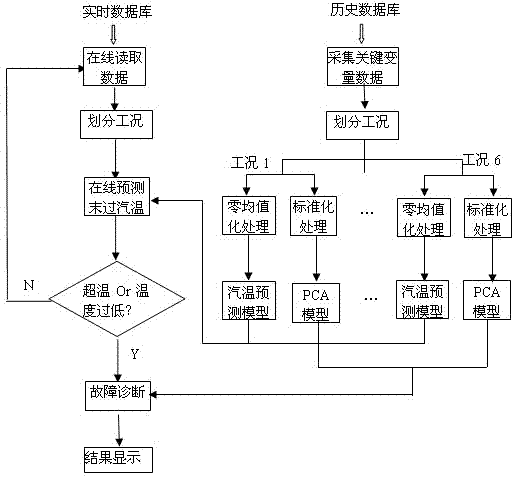

[0047] The present invention will be further described below in conjunction with the accompanying drawings. The embodiments of the present invention are used to explain the present invention, but not to limit the present invention.

[0048] The steps of the superheated steam temperature abnormal early warning and fault diagnosis method of DC million units are as follows:

[0049] 1) Divide working conditions according to unit load, select 10% of full load as the load section selection rule, and determine 6 typical working conditions from 45% to 100% of full load; typical working conditions of million units can be divided as follows: 450MW ~550MW, 550MW~650MW, 650MW~750MW, 750MW~850MW, 850MW~950MW and above 950MW.

[0050] 2) Read the data of key variables during normal operation under each load condition from the DCS historical database as the corresponding training samples ; The key variable is: superheated steam temperature prediction model variable and fault diagnos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com