System for controlling forecast of molten steel temperature of double-station LF furnace

A molten steel temperature and control system technology, applied in the direction of temperature control, control/regulation system, electrical program control, etc., can solve problems such as forecasting and control systems that have not been required for industrial applications, and achieve automatic control of molten steel temperature, accurate forecasting, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

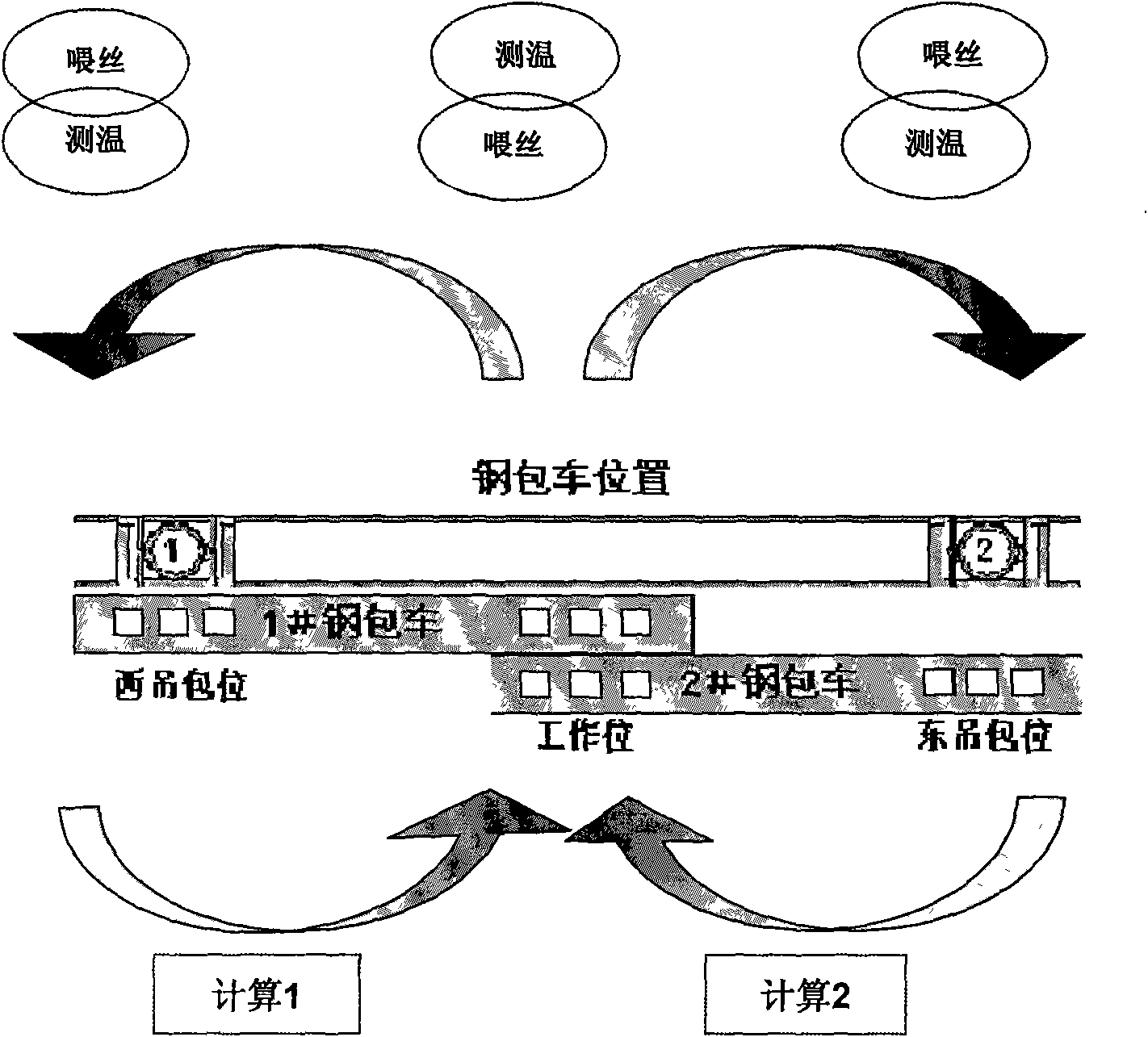

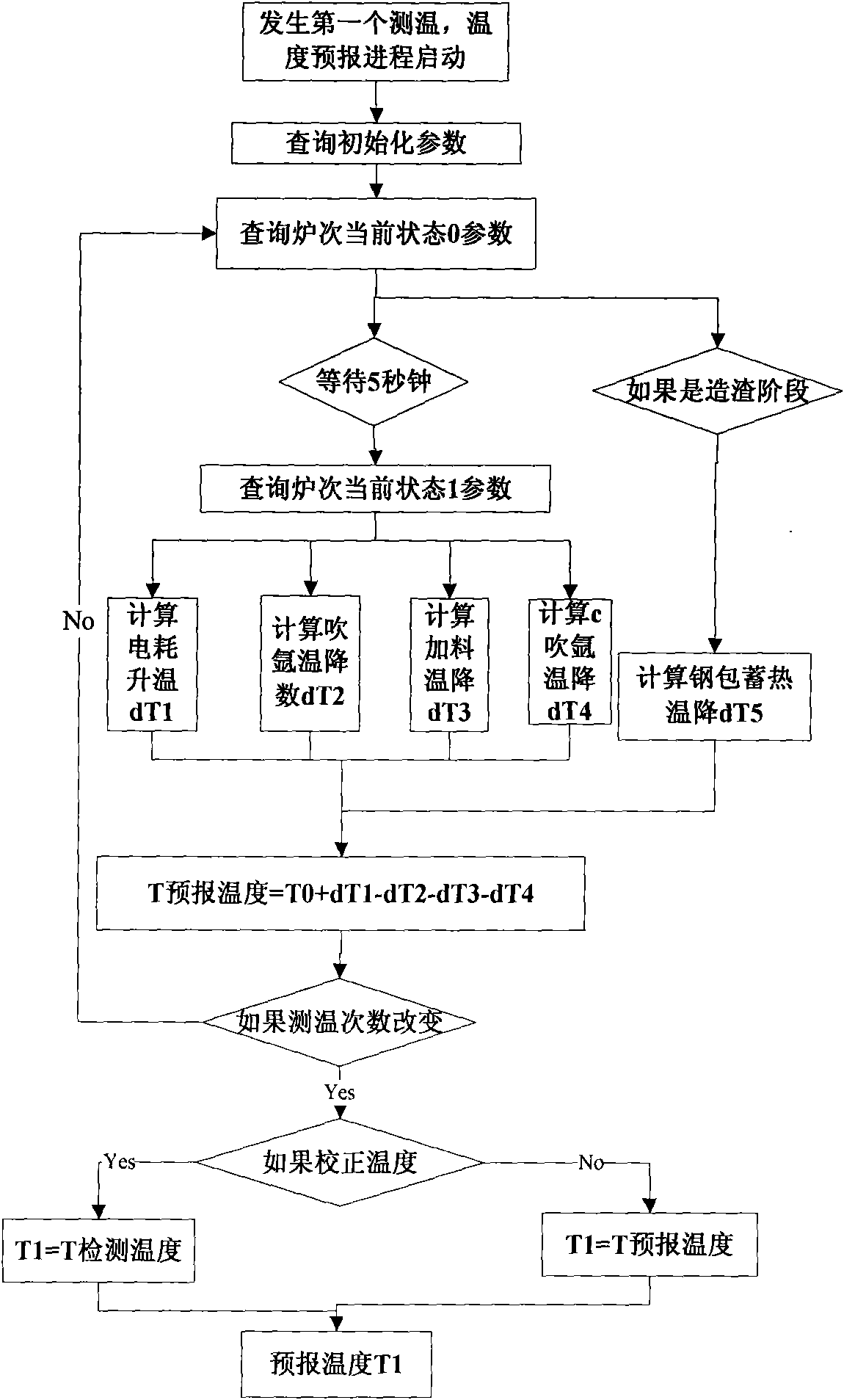

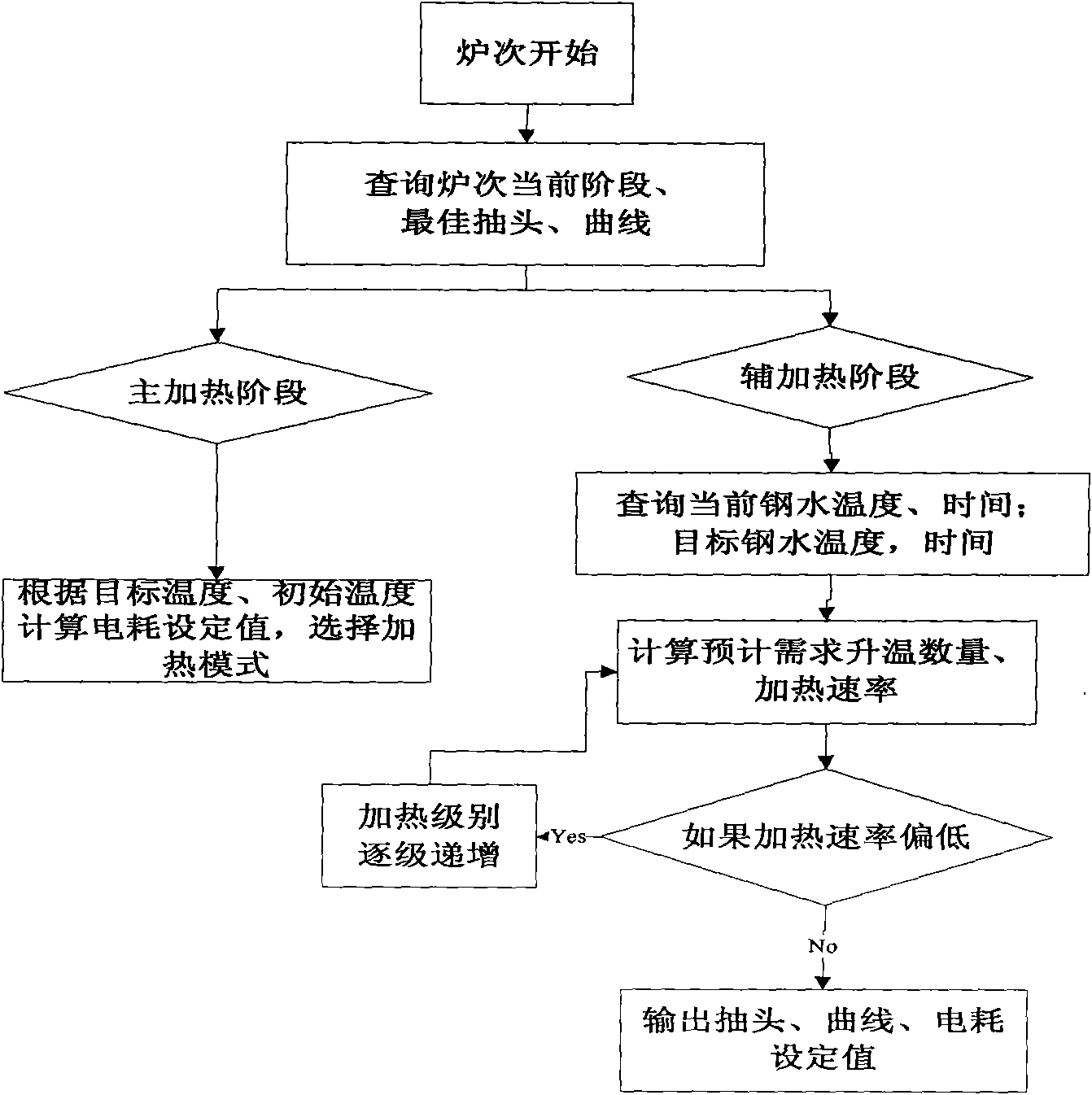

[0045] This system automatically collects the temperature measurement information of the first-level system, writes it into the L2 server, and writes it into the corresponding 1# and 2# furnace table as the basic data after being judged by the temperature correction module. Establish temperature prediction module, control module, and parameter self-learning module to optimize the temperature control of molten steel in LF furnace: the molten steel temperature prediction module is based on the metallurgical principle module and self-learning module, and calculates the temperature change increment of molten steel within the interval; the temperature control module is based on real-time Forecast molten steel temperature and target temperature requirements, and calculate electrode heating mode.

[0046] 1. The specific implementation method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com