Decision tree-based method for extracting key characteristic variables of finish rolling temperature control process

A key feature, temperature control process technology, applied in temperature control and other directions, can solve problems such as failure to achieve real-time control, few effective temperature measurement points, and lag in the impact of final rolling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

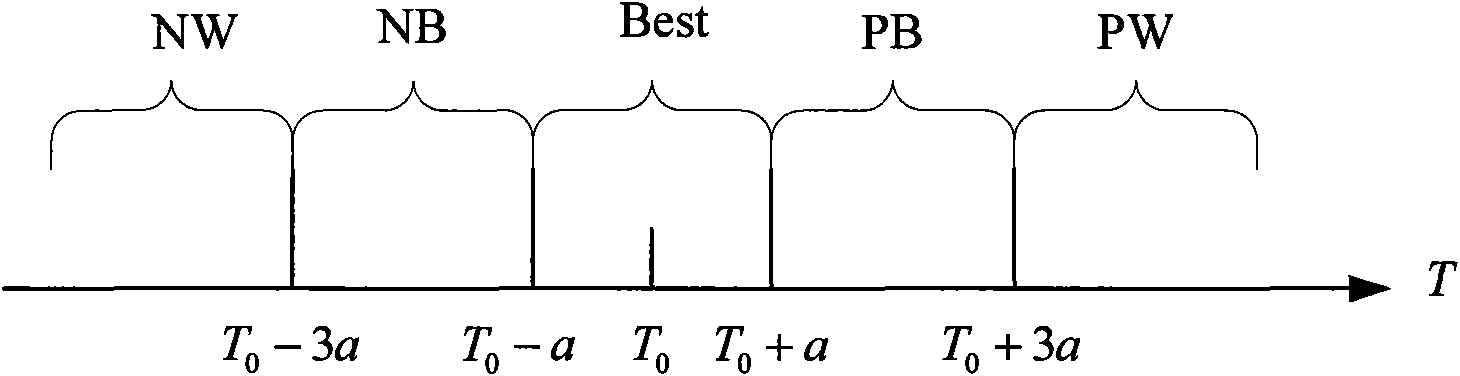

AI Technical Summary

Problems solved by technology

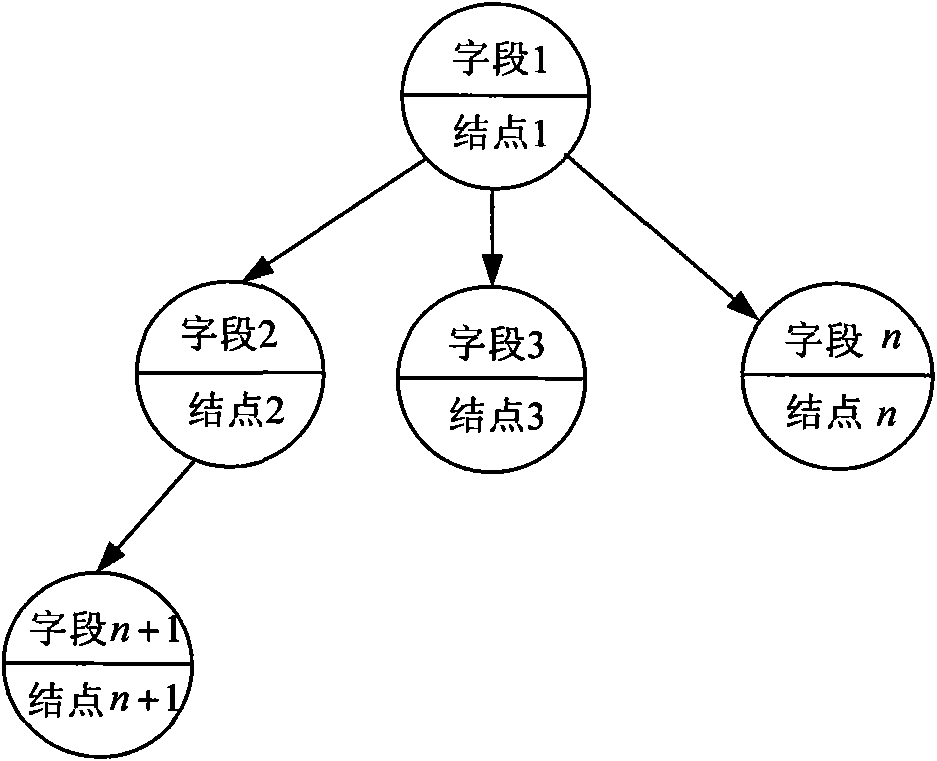

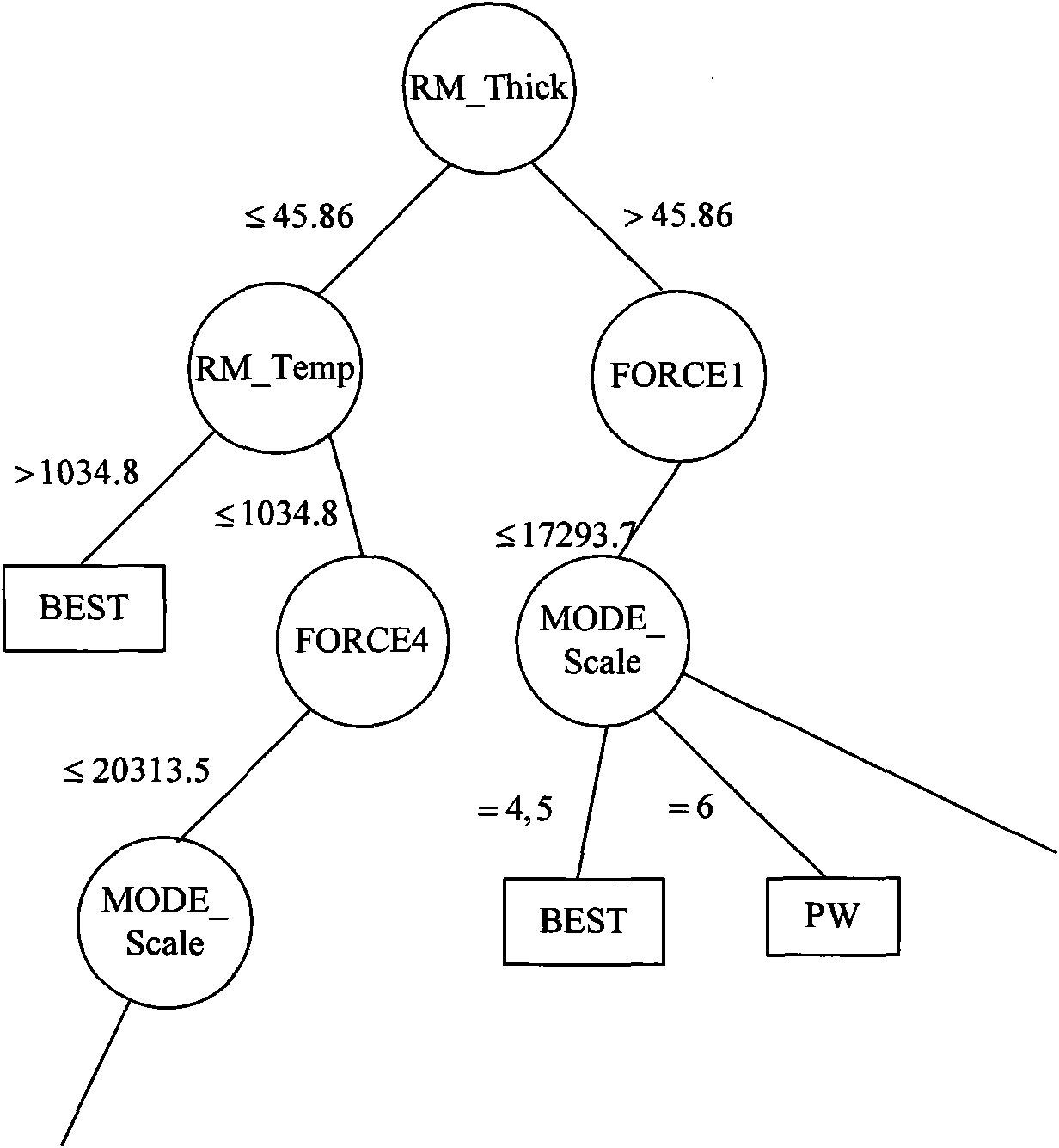

Method used

Image

Examples

Embodiment Construction

[0072] The few field data in the four series of data of the three steel strips are listed below. Their strip numbers are 9232000400, 9232000500 and 9232000600 respectively.

[0073] It is known that the final rolling target temperature of the three strips is 880°C, and the actual final rolling temperature of each section is shown in Table 2.

[0074] The data of the finish rolling process of the three steel strips are shown in Table 3-6.

[0075] Table 2 Three-stage finish rolling temperature of three strips

[0076]

[0077] Table 3 Data series 1 of the three strips

[0078]

[0079] Table 4 Data series 2 of the three strips

[0080]

[0081] Table 5 Data series 3 of the three strips

[0082]

[0083] Table 6 Data series 4 of the three strips

[0084]

[0085]

[0086]

[0087] Firstly, step a) is performed to preprocess the above massive finishing rolling process data, including denoising and data sorting.

[0088] Traversing the data fields of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com