Phase-field method-based microstructure evolution simulation method in welding process in transient state

A technology of microstructure and welding process, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not fully reflecting the evolution of the microstructure of the welding pool, lack of solidification theoretical basis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

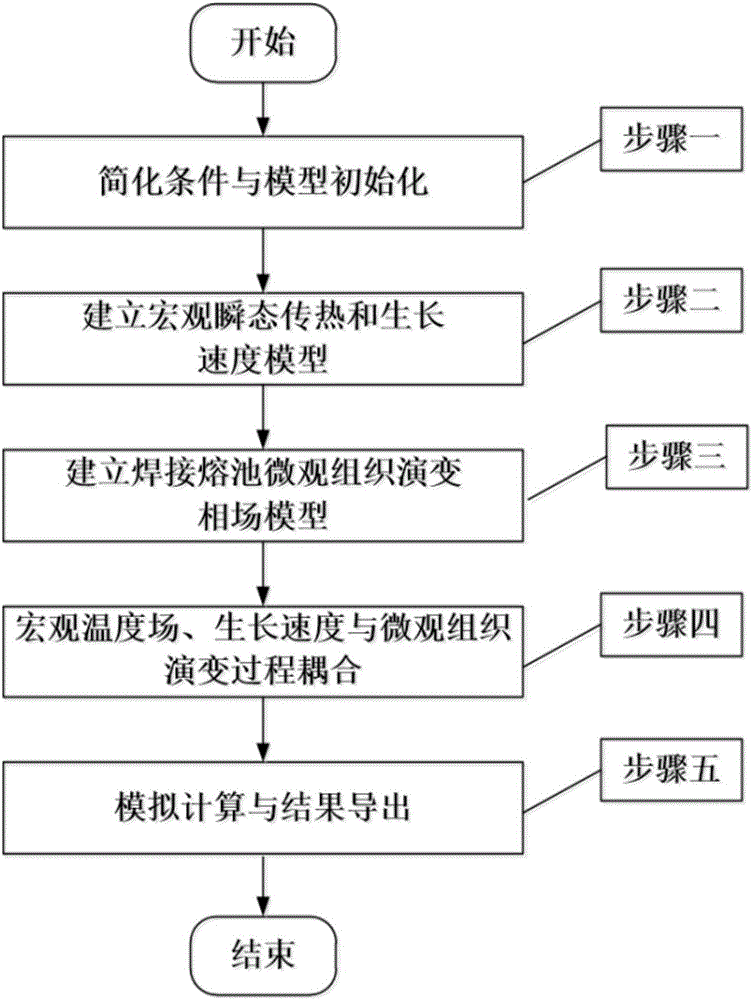

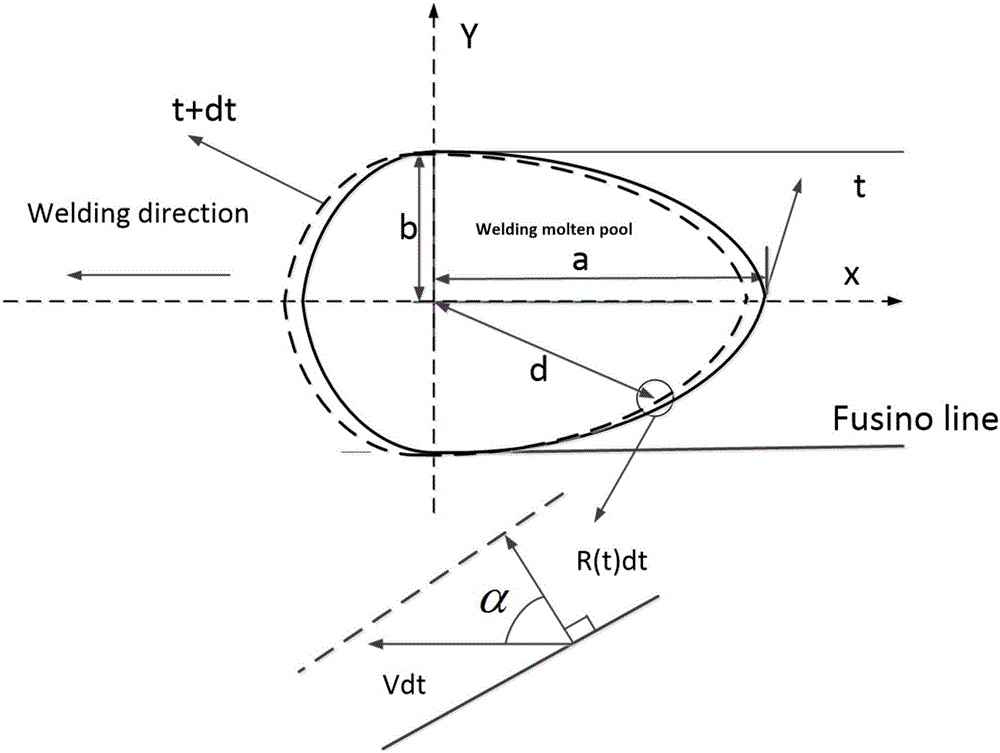

Method used

Image

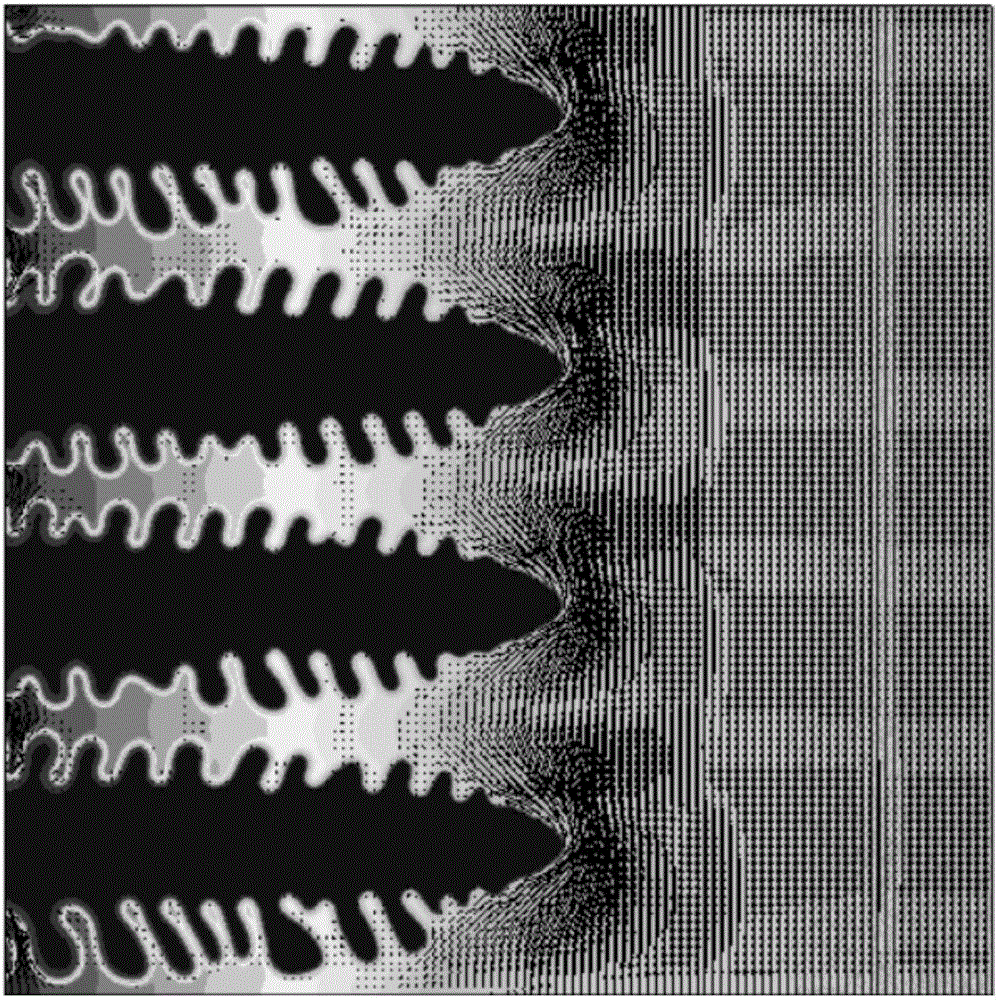

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0056]Unless the context clearly states otherwise, the number of elements and components in the present invention can exist in a single form or in multiple forms, and the present invention is not limited thereto. Although the steps in the present invention are arranged with labels, they are not used to limit the order of the steps. Unless the order of the steps is clearly stated or the execution of a certain step requires other steps as a basis, the relative order of the steps can be adjusted. It can be understood that the term "and / or" used herein refers to and covers any and all possible combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com