Cable-joint cable core temperature inversion method and system on basis of surface temperature of cable

A technology of surface temperature and cable joint, applied in the field of cable joint cable core temperature inversion method and system, can solve problems such as cable accident, overheating burn-through of accessories, insulation aging, etc., and achieve the effect of ensuring safe operation and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

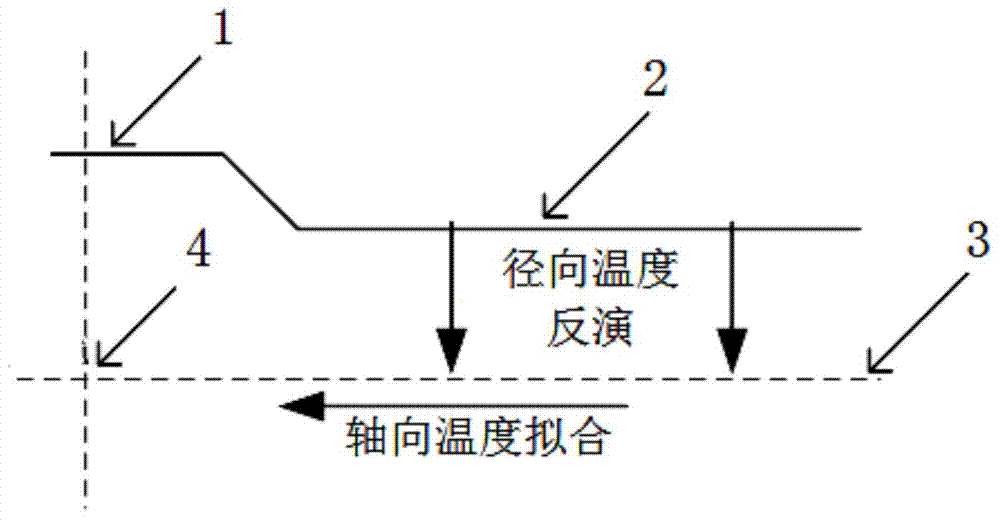

[0044] figure 1 It is a schematic diagram of the principle of the present invention, from which it can be seen that the present invention is characterized in that the temperature of the cable core contact point (4) at the cable joint is obtained by combining radial temperature inversion and axial temperature fitting. The so-called cable core contact point refers to the contact surface of the two cable cores inside the cable joint, where the temperature is the highest due to the relatively large contact resistance.

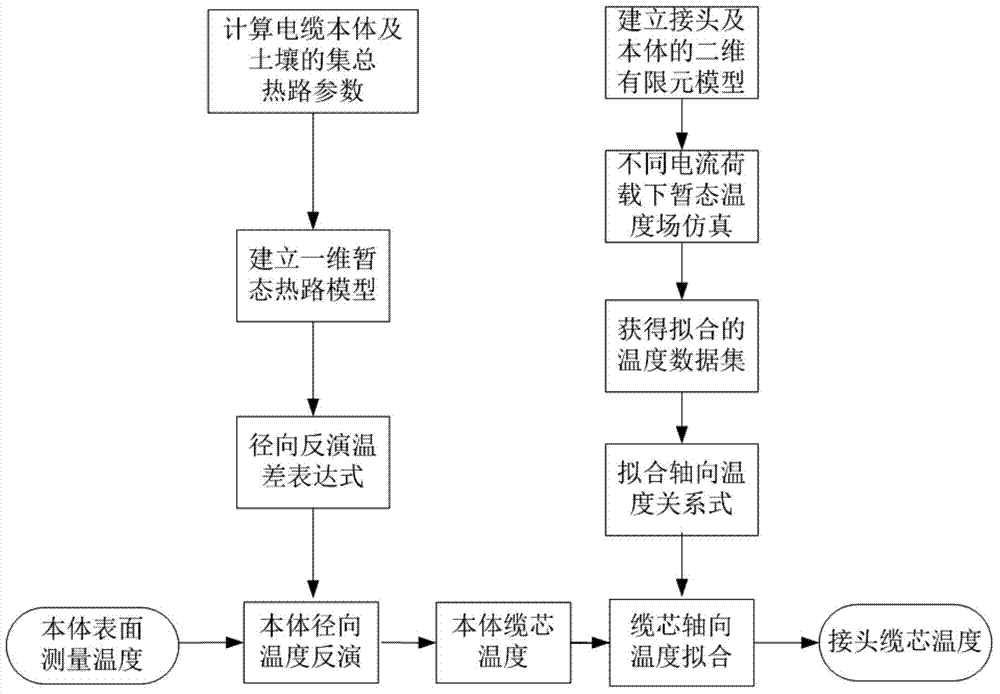

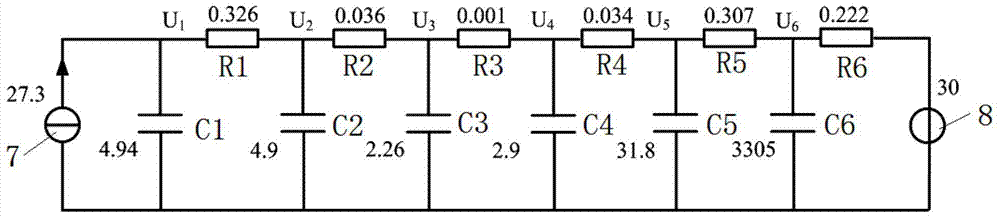

[0045] figure 2 It is a specific flow chart of the present invention, mainly including two parts: radial temperature inversion and axial temperature fitting. Radial temperature inversion means: according to the structure and material parameters of the cable body, as well as the soil structure and material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com