Optical fiber ring quality measurement method and its device for optical fibre gyroscope

A fiber optic gyroscope and measurement method technology, which is applied in the direction of testing optical performance, etc., can solve the problems of working characteristic interference, judging the quality of fiber optic rings, and measuring the transient characteristics of temperature, so as to achieve accurate measurement and judge the quality of fiber optic rings intuitively and accurately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

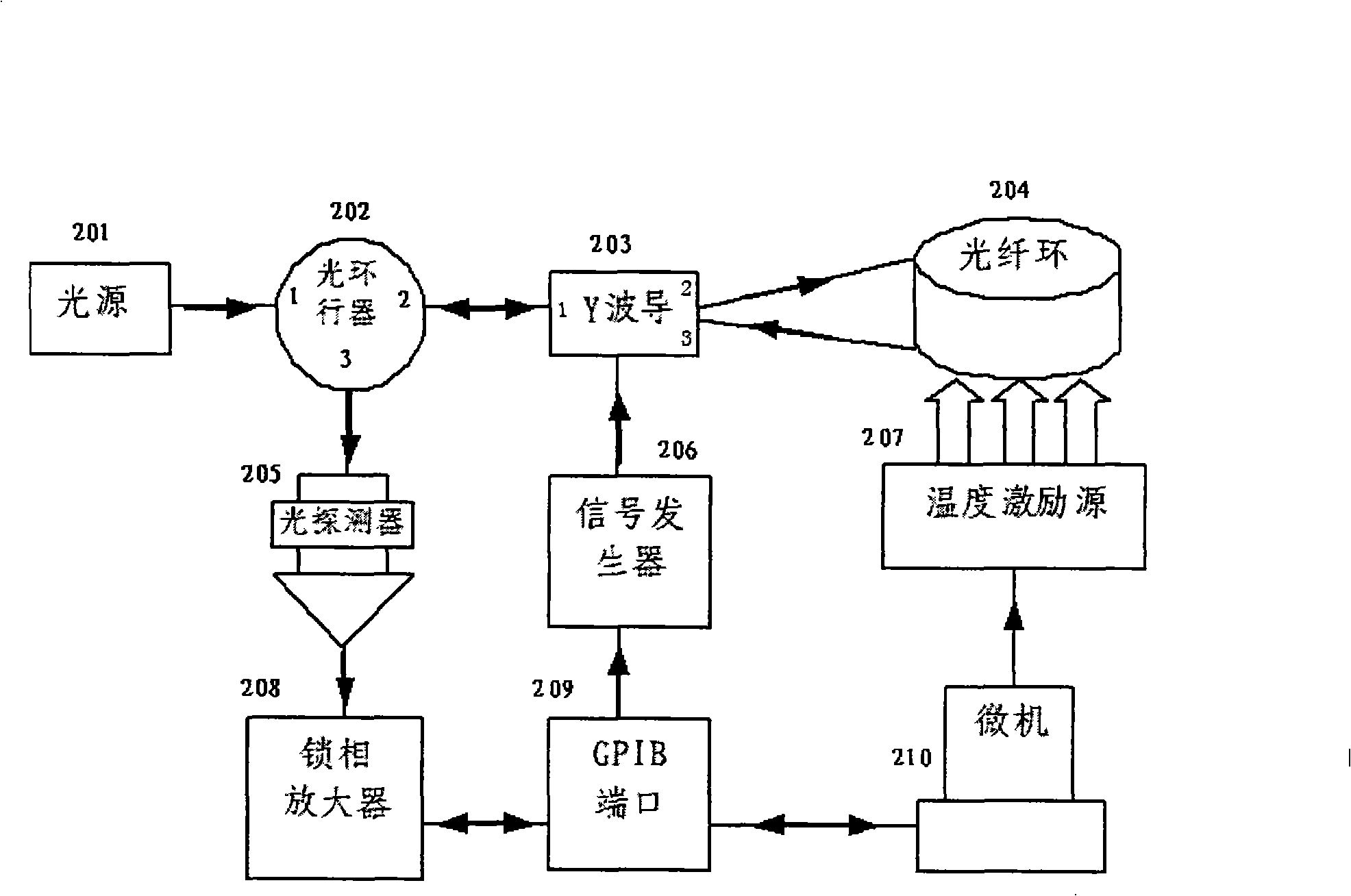

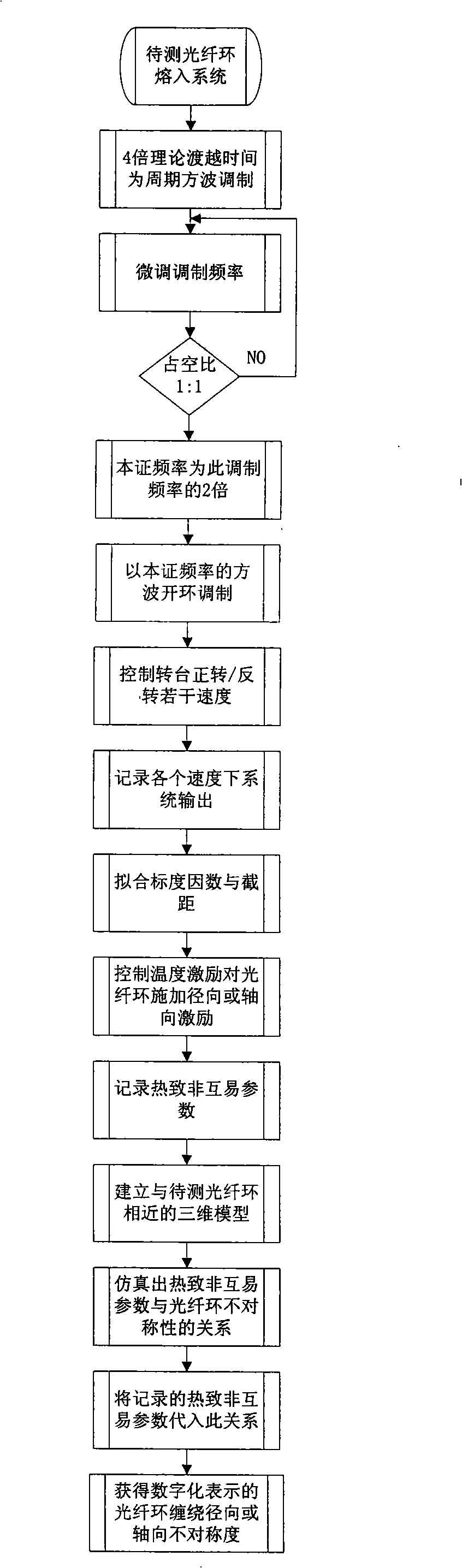

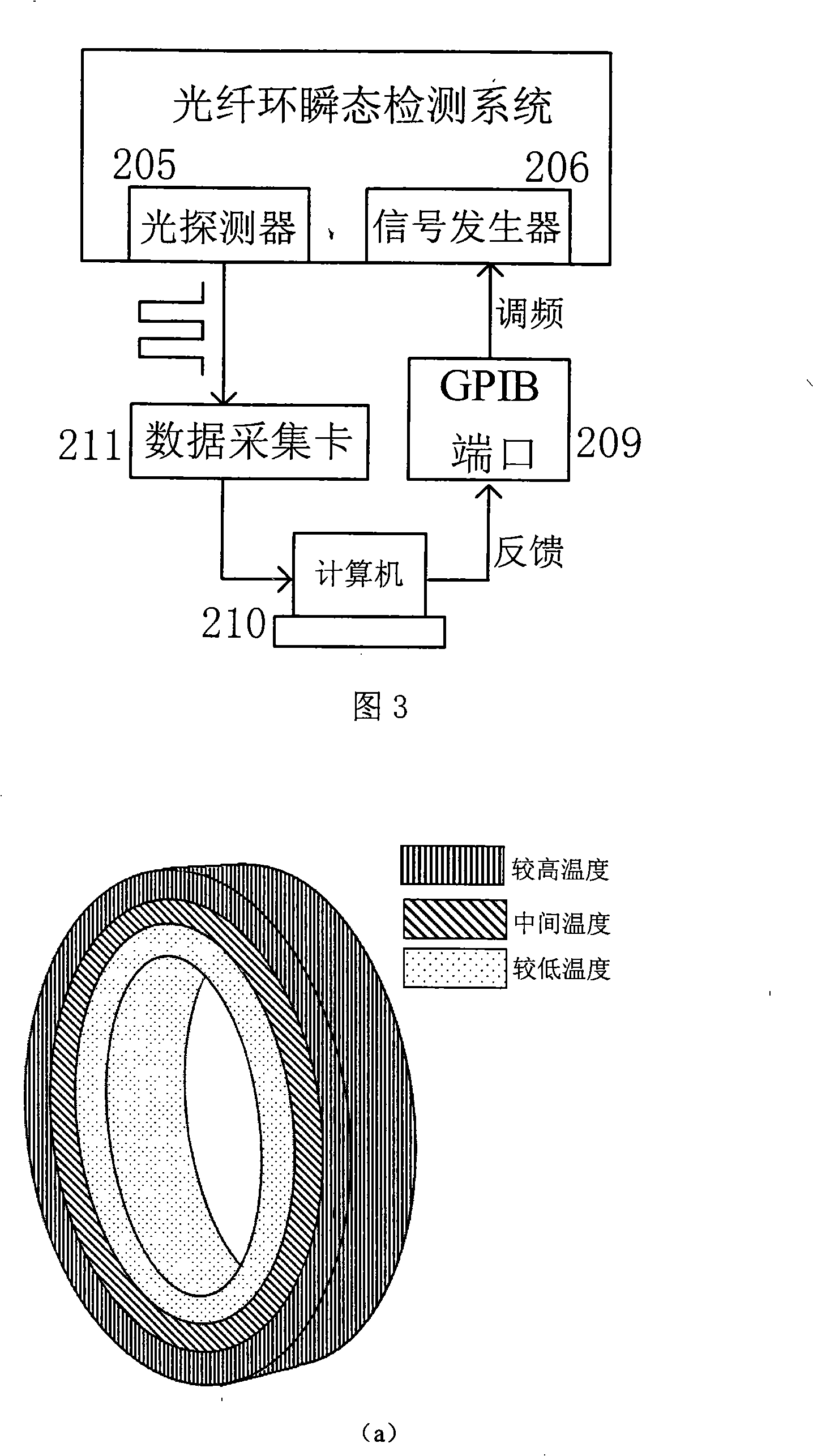

[0065] The basic principle of the present invention is to connect a fiber optic ring to be tested to the fiber optic gyroscope system, and obtain a relationship between the rotation and output of the gyroscope by measuring the signal output at different rotational angular velocities. This relationship can be obtained through a mathematical relationship expression (the present invention establishes a three-dimensional mathematical model for this purpose; using this mathematical relational expression, the rotation of the optical fiber ring can be known more intuitively and accurately by measuring the output of the optical fiber ring). Then put the optical fiber ring in a static state, and perform temperature excitation on it. If the winding symmetry of the optical fiber ring is not good, there will be a signal output corresponding to the rotation. At this time, substitute the output value of such a signal into the previously obtained relational formula, you can Inversely calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com