Electric submersible pump well production IOT system

A networked system, electric submersible pump technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of low efficiency, high labor intensity, poor real-time data, etc., to achieve simple process flow, reduce input costs, The effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

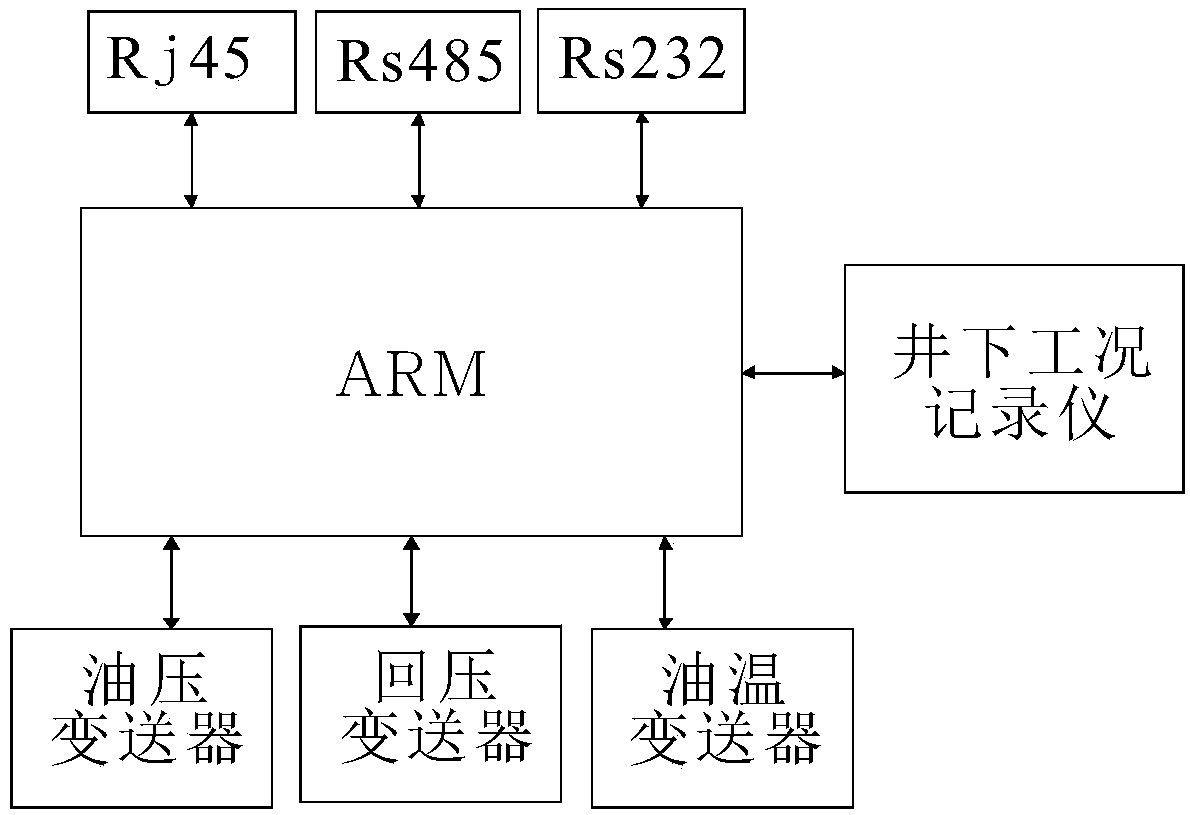

[0009] Such as figure 1 As shown, the electric submersible pump well production Internet of Things system disclosed in the present invention includes: a remote terminal controller (RTU), an oil pressure transmitter, a back pressure transmitter, an oil temperature transmitter and a downhole working condition recorder; , the remote terminal controller is equipped with ARM processor, RJ45 network interface, RS485 data interface and RS232 data interface; oil pressure transmitter, back pressure transmitter and oil temperature transmitter are connected to the electric submersible pump well, The data interface is connected to the remote terminal controller; the downhole working condition recorder is connected to the electric sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com