Integrated device for testing lithium ion battery and shaping and cutting battery lug

A lithium-ion battery and battery tab technology, applied in battery electrodes, measuring devices, non-aqueous electrolyte batteries, etc., can solve problems such as increasing labor costs of enterprises, puncturing batteries by test pens, and inability to guarantee battery quality, saving time and effort. Quality, quality assurance, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

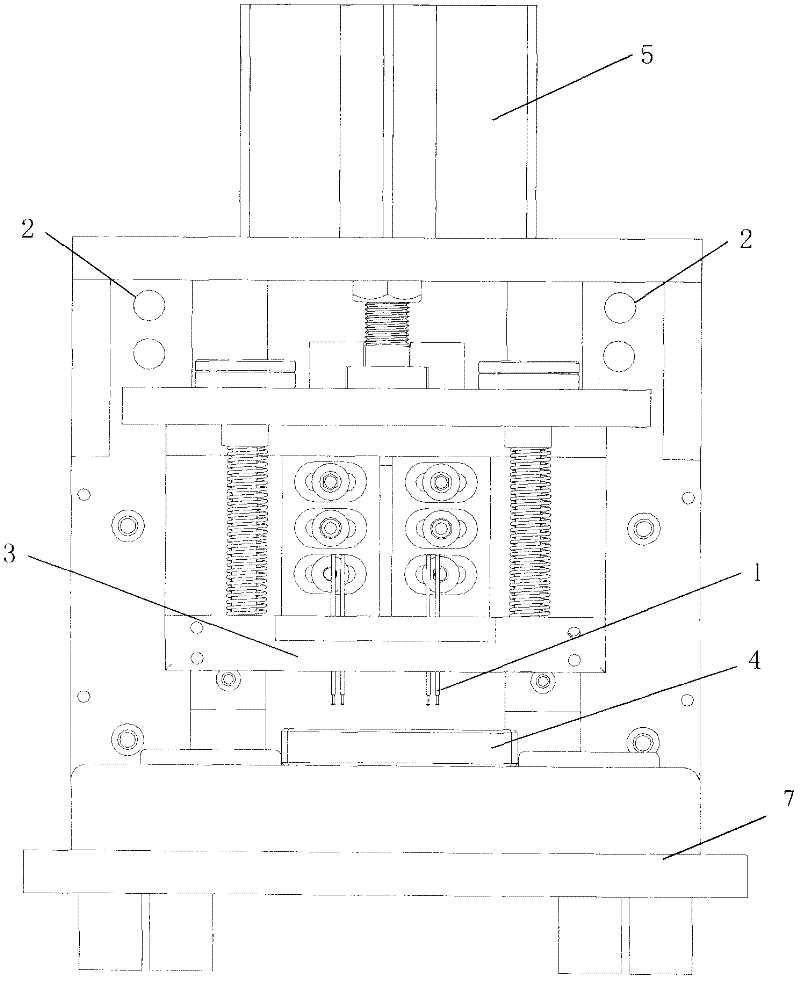

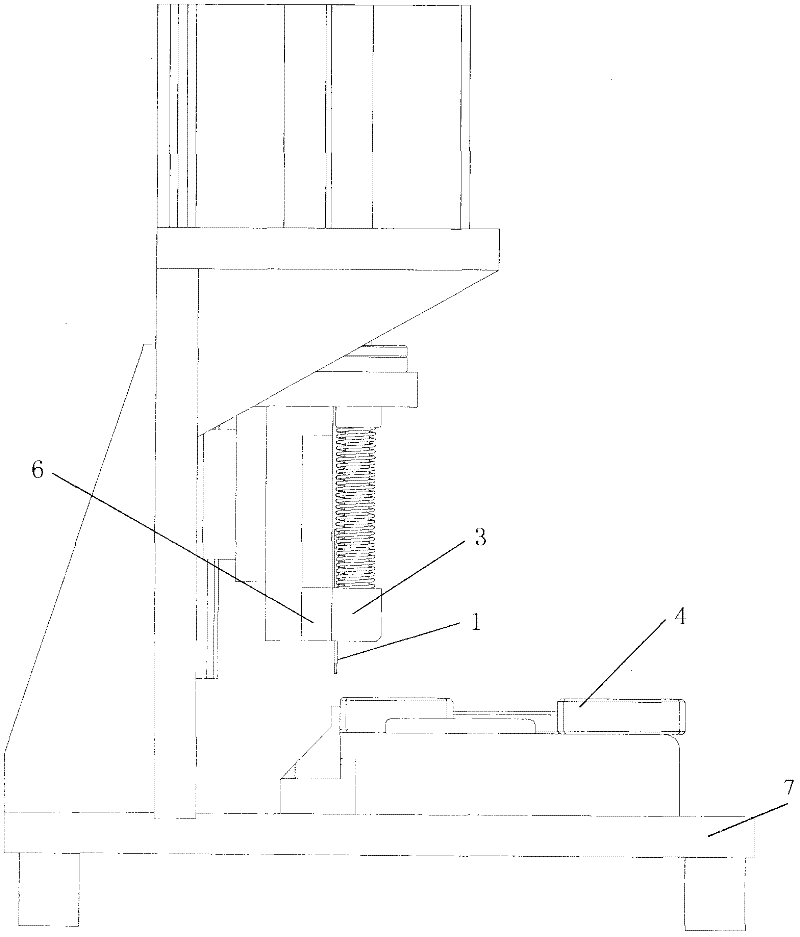

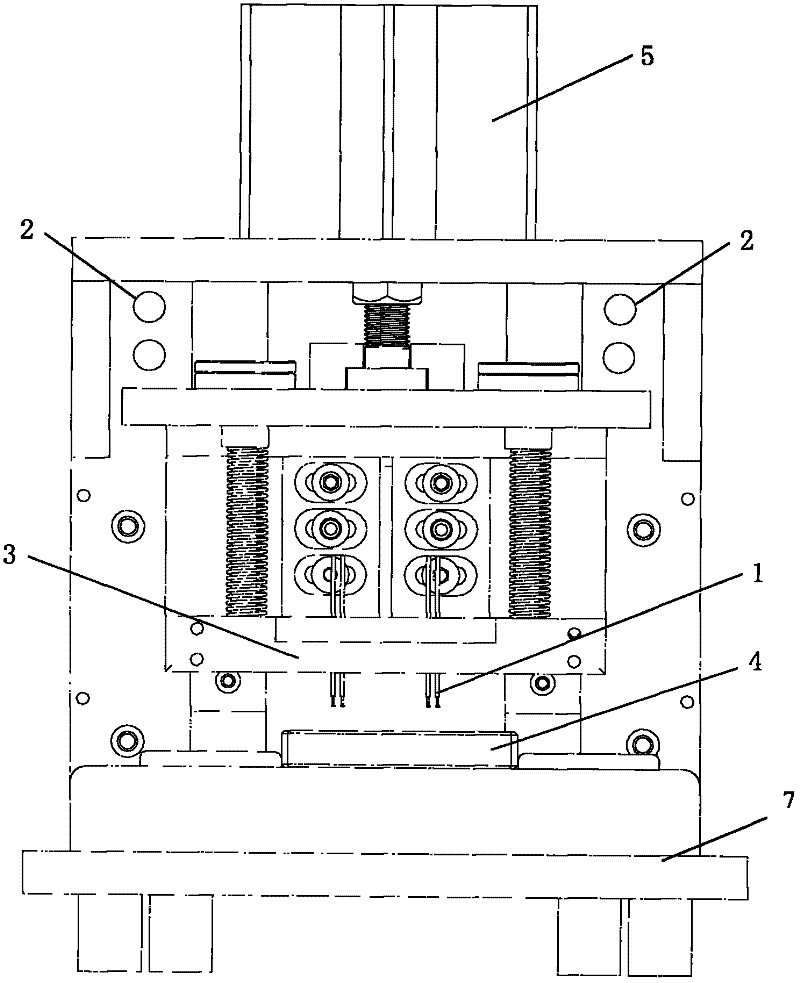

[0009] Such as figure 1 , figure 2 As shown, an integrated device for lithium-ion battery testing and battery lug shaping and cutting is designed, including a base 7, a semi-automatic cutting machine arranged on the base 7, the semi-automatic cutting machine includes a cylinder 5, connected to the drive end of the cylinder The cutting knife and the shaping pressing block 3, the positioning battery fixture 4 fixed on the machine base 7 is arranged under the shaping pressing block 3, and the positive and negative two sets of probes are inlaid on the strip shaped shaping pressing block 3 of the shaping battery tab. Pin 1, the positive and negative probes 1 are respectively connected to the external test lead slot 2 on the periphery of the device by wires. Test lead.

[0010] It consists of a semi-automatic cutting machine, a plastic pressing block 3, a probe 1 and its connecting wire, a test lead socket 2, and a fixture for positioning the battery 4. The number of positive an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com