Patents

Literature

98results about How to "Reduce residual risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

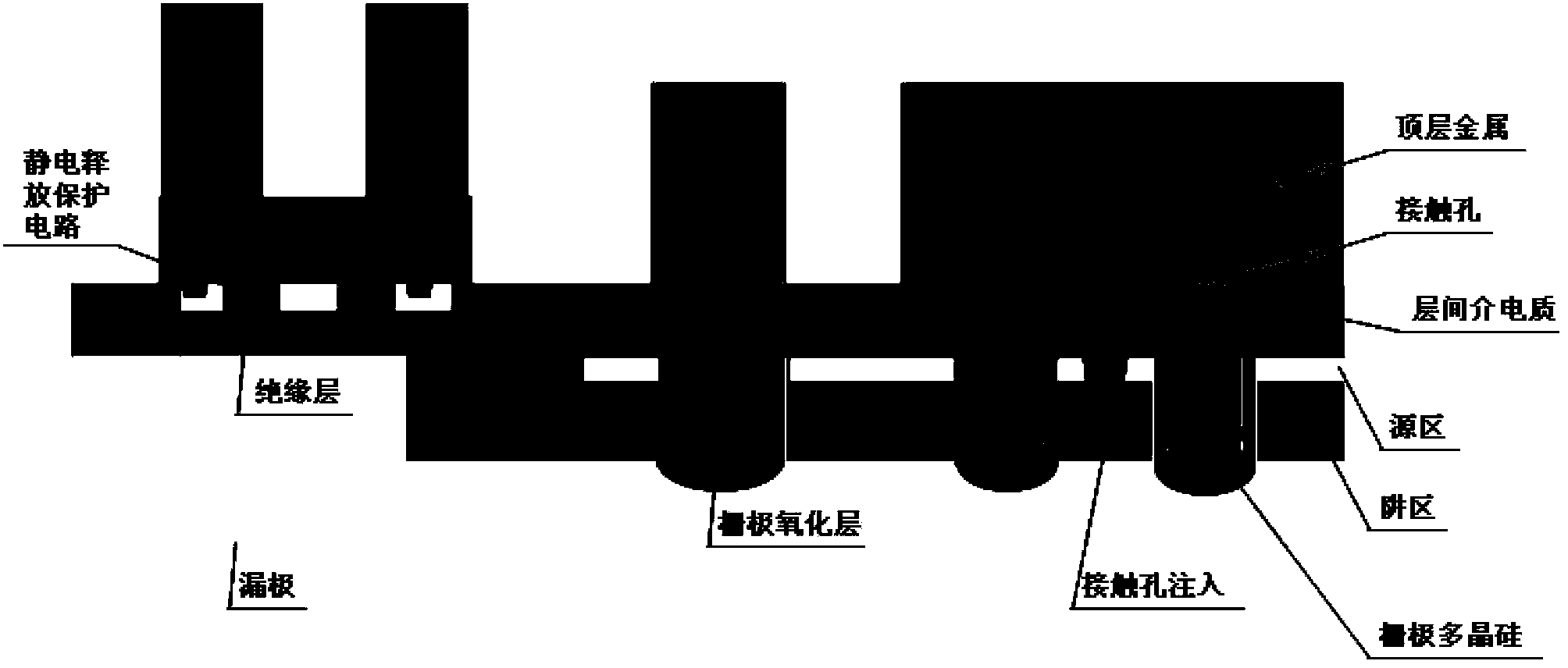

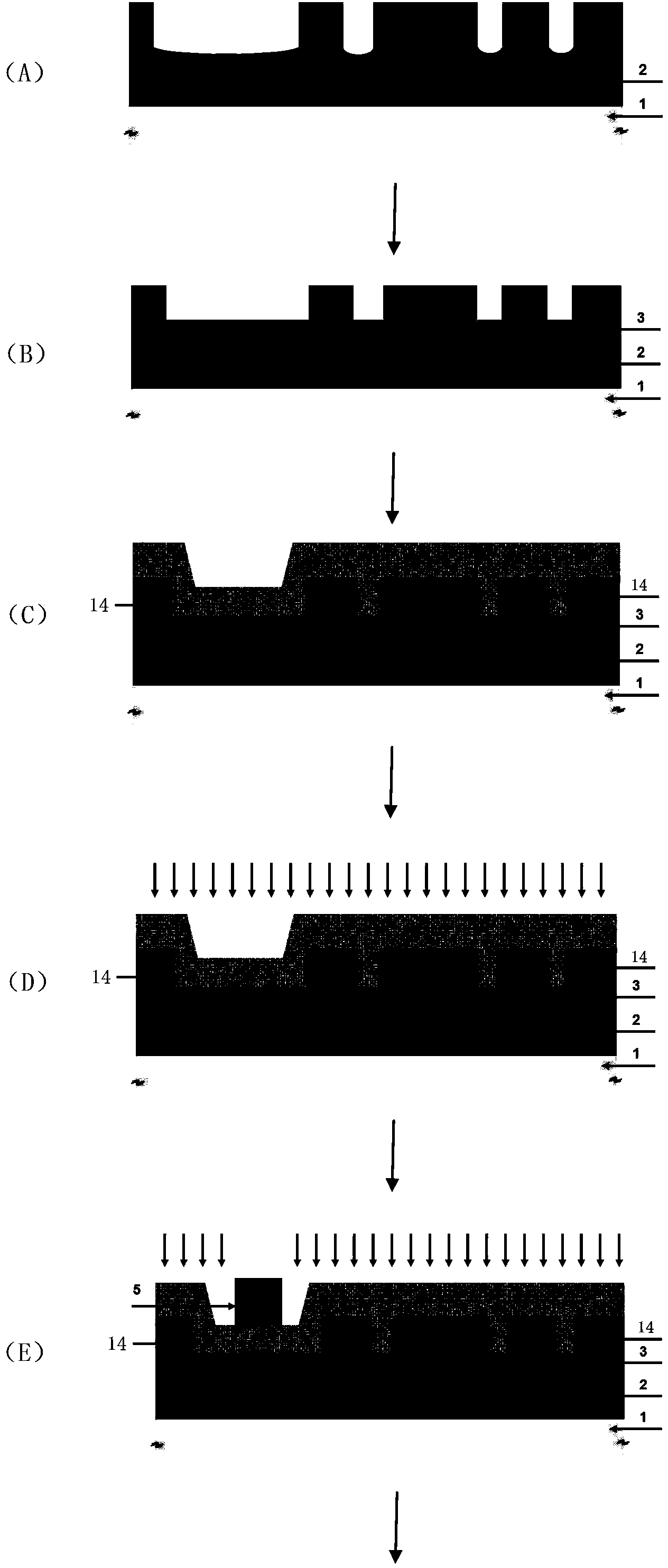

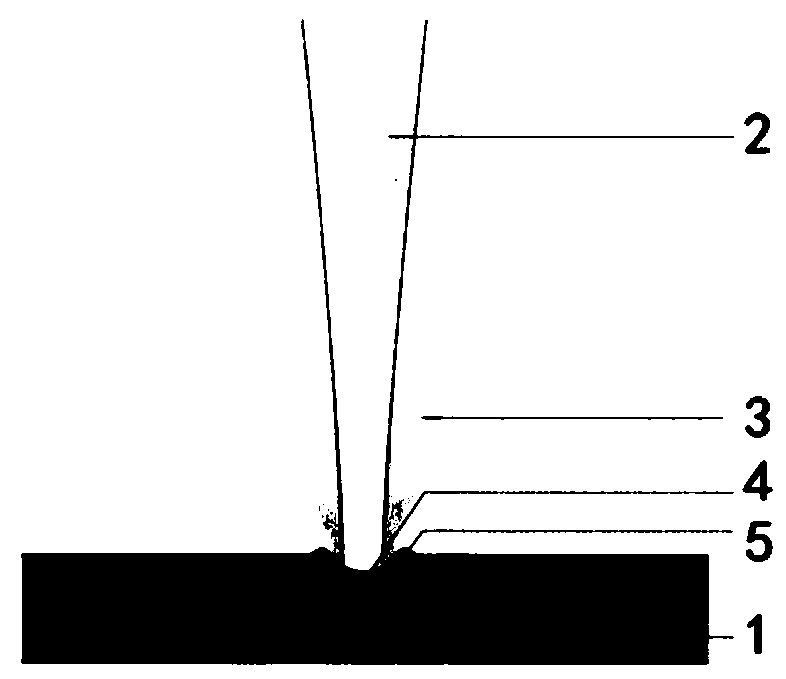

Manufacturing method of groove type MOS (Metal Oxide Semiconductor) transistor with electrostatic discharge protection circuit

ActiveCN104347422AReduce residual riskImprove flatnessSemiconductor/solid-state device manufacturingEtchingNon doped

The invention discloses a manufacturing method of a groove type MOS (Metal Oxide Semiconductor) transistor with an electrostatic discharge protection circuit. The manufacturing method comprises the following steps: (1) carrying out epitaxial growth and groove etching; (2) carrying out groove bottom thick grid oxygen deposition and back etching; (3) carrying out non-doped polycrystalline silicon deposition; (4) carrying out primary polycrystalline injection; (5) carrying out secondary polycrystalline injection; (6) carrying out polycrystalline silicon back etching to form grid electrode polycrystalline silicon and electrostatic discharge protection circuit polycrystalline silicon; (7) carrying out trap injection; (8) carrying out source injection. An inter-layer medium layer, a contact hole, top layer metal and back metal are formed in a follow-up step according to a conventional process. On the basis of a traditional process, a groove bottom thick grid oxygen structure is used as an insulating layer between the electrostatic discharge protection circuit and a groove power device, and then the polycrystalline deposition is carried out; photoetching partitioned injection and back etching are combined to form groove polycrystalline silicon and the electrostatic discharge protection circuit polycrystalline silicon; one active region photoetching layer and primary polycrystalline silicon deposition and back etching are reduced, so that the technological process is shortened.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

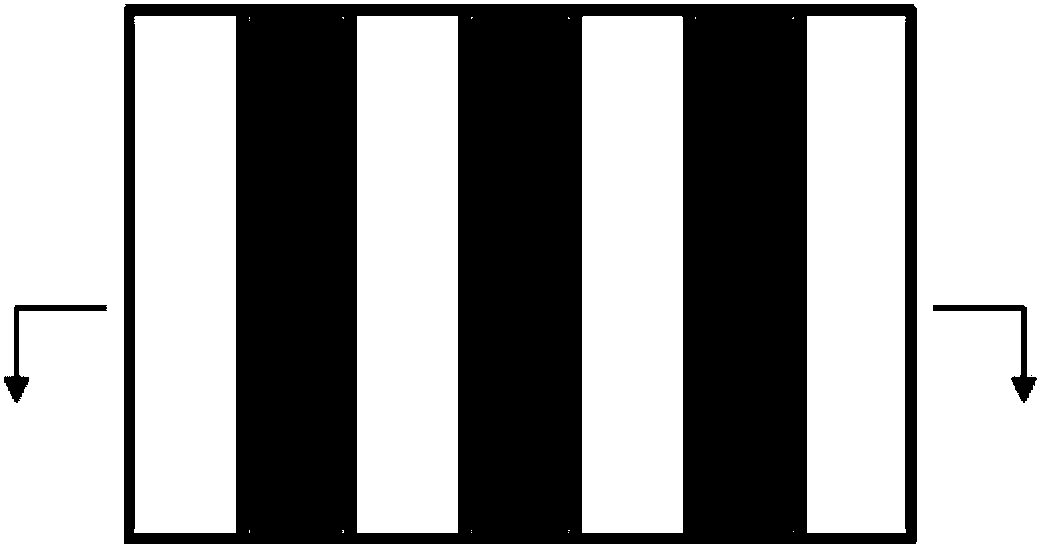

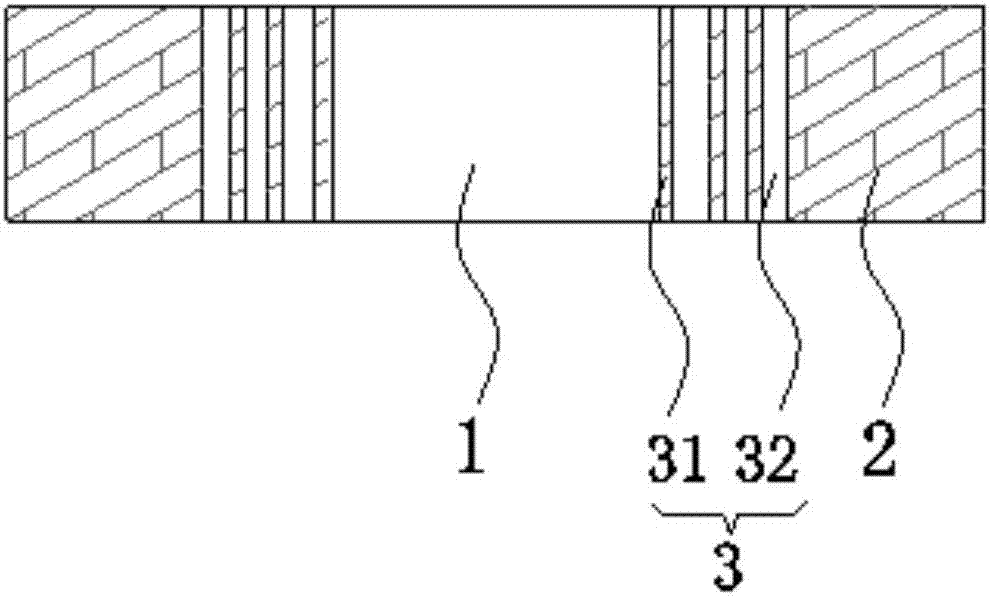

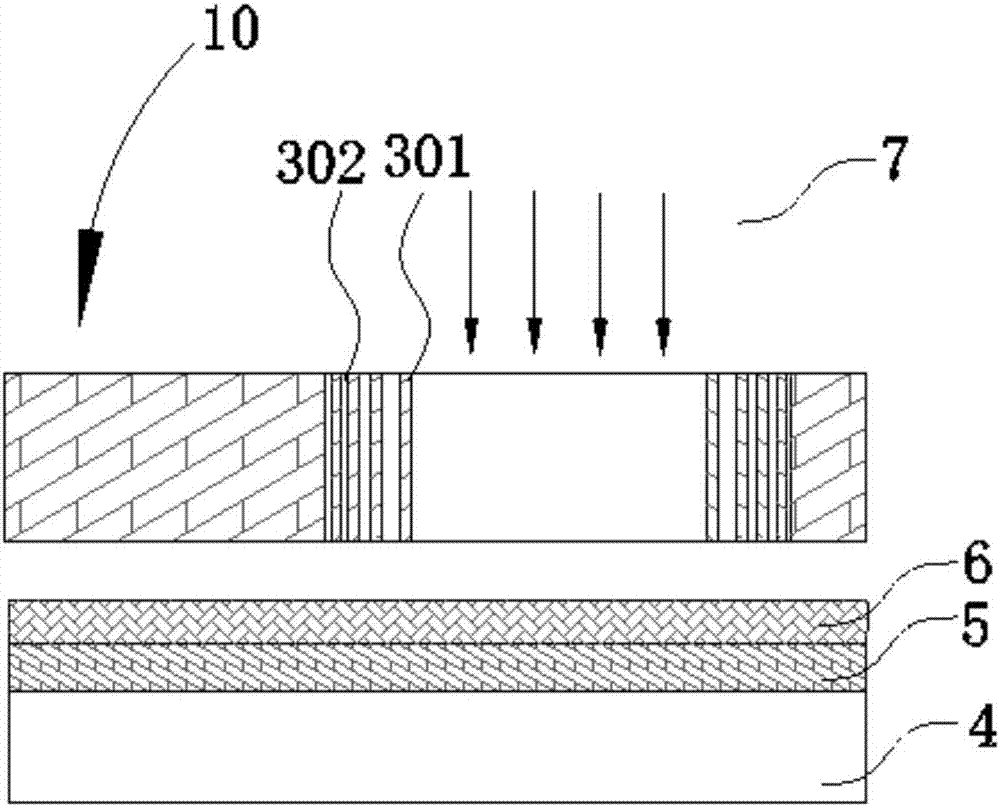

Photomask and glass substrate manufacturing method

InactiveCN106933023AAvoid breakingReduce residual riskOriginals for photomechanical treatmentNon-linear opticsTransmittanceGap width

The invention brings forward a photomask, which comprises a photic zone and an antihalation zone. The photomask also comprises a partial photic zone, which is positioned between the antihalation zone and the photic zone to allow light to partially permeate. The partial photic zone comprises several equal shading films. A light-permeable gap is formed between adjacent shading films. Transmittance of the partial photic zone is gradually reduced along the direction from the photic zone towards the antihalation zone. The invention has the following beneficial effects: with the arrangement of the partial photic zone with light-permeable gap width changing on the basis of functional rules along the direction from the photic zone towards the antihalation zone, photoresistive exposure degree of the corresponding partial photic zone is controlled such that the edge of the film after etching and stripping becomes a smooth, cambered surface or other forms of transition surface, it is ensured that a next film folded thereon is not easy to break during climbing, and the residual risk of the film at the taper angle during the follow-up processing treatment is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

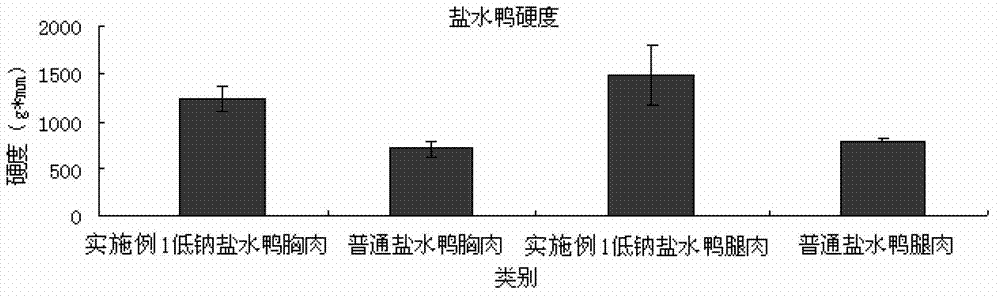

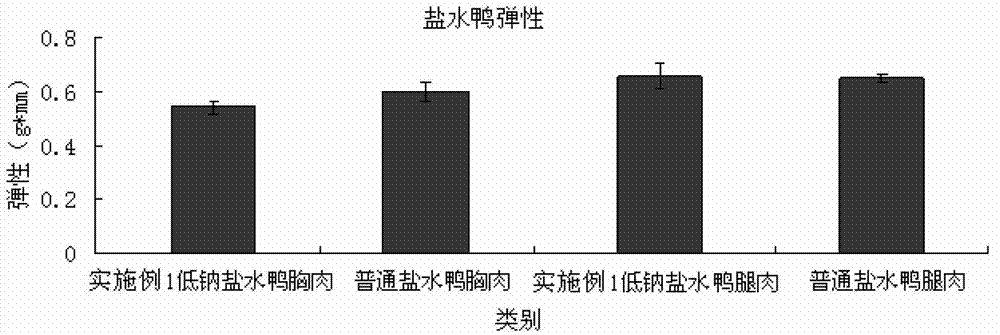

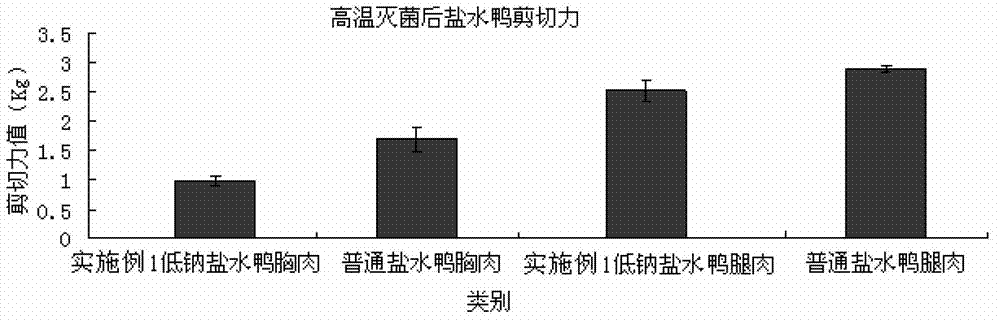

Processing technology of low-sodium crisp and tender salted waterfowl-meat product

ActiveCN102960746AReduced risk of hazardous substance residuesShorten the timeFood preparationFlavorLow sodium

The invention discloses a processing technology of a low-sodium crisp and tender salted waterfowl-meat product. The processing technology comprises the following steps in sequence of: dry-salting, injecting, tumbling, drying by jetting hot air, cooling, packaging, and sterilizing at high temperature, thus obtaining the low-sodium crisp and tender salted waterfowl-meat product. By adopting the new technology, the processed low-sodium crisp and tender salted waterfowl-meat product has the flavor and salinity close to those of traditional salted waterfowl-meat product; and the low-sodium crisp and tender salted waterfowl-meat product contains sodium which is 41.36 to 53.02% that in traditional salted waterfowl-meat product. According to the new process, the way in combination of dry-salting and tumbling is carried out, the flavor of the spices is penetrated into the waterfowl meat, so that the conventional flavor of the waterfowl-meat product can be ensured, and the risk of the harmful substance residual in the product can be reduced; according to the new process, a hot-air jetting drying technology is adopted to dry the waterfowl-meat product in three stages, so that the time can be saved, the temperature and humidity of the skin of the waterfowl meat can be adjusted and controlled by controlling the speed and the temperature of the hot air and injecting a water-retaining agent and adding a color fixative, and the texture, color and gloss of the waterfowl meat and the skin can be adjusted and controlled within certain time, and therefore the waterfowl-meat product is crisp and tender after being sterilized at high temperature.

Owner:河南优兰食品科技有限公司

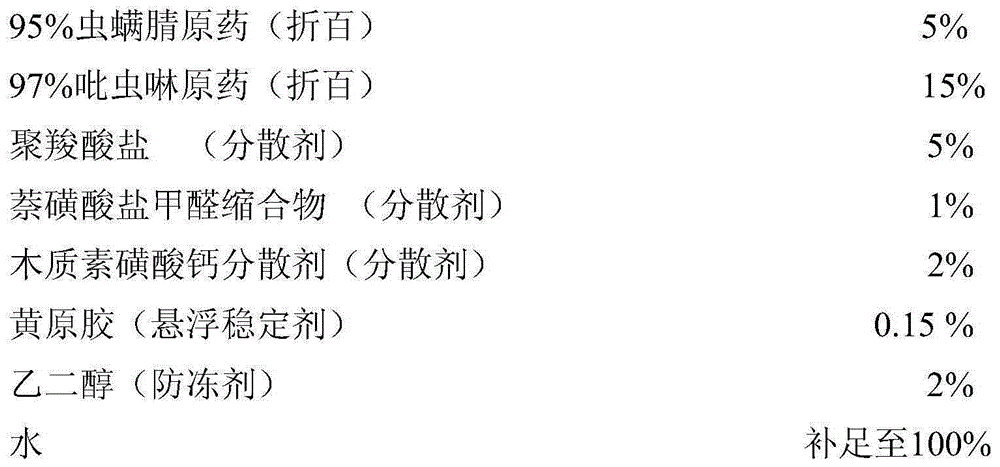

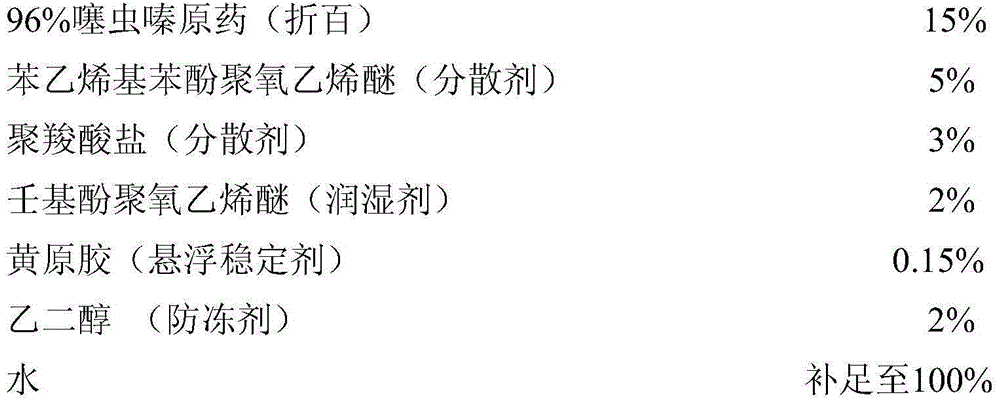

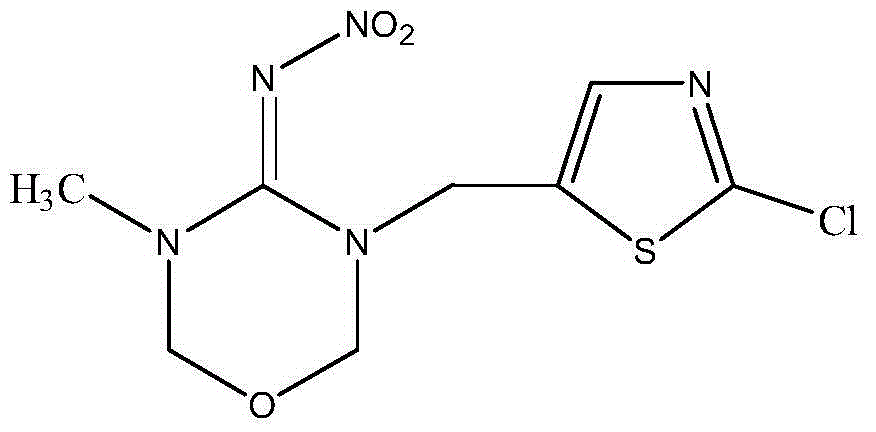

Insecticide composition with chlorfenapyr and neonicotinoid insecticides, and preparation and application of insecticide composition

ActiveCN105076185ASynergistic effect is obviousExtended service lifeBiocideAnimal repellantsClothianidinChlorfenapyr

The invention discloses an insecticide composition with chlorfenapyr and neonicotinoid insecticides, and a preparation and application of the insecticide composition. The insecticide composition comprises the chlorfenapyr and the neonicotinoid insecticides. The neonicotinoid insecticides are an optional type of imidacloprid, thiamethoxam, clothianidin, nitenpyram, thiacloprid, dinotefuran and acetamiprid. A mass ratio of the chlorfenapyr to the neonicotinoid insecticides is (0.05-20):1. An insecticide comprises the insecticide composition and auxiliary materials acceptable to the insecticide preparation with the insecticide composition. A mass percent content of the insecticide composition in the insecticide is 2%-6%. The insecticide composition, the preparation and the application have the advantages that obvious synergism effects can be realized for bradysia odoriphaga; the chlorfenapyr and the neonicotinoid insecticides have different action mechanisms, accordingly, the insecticide composition is beneficial to delaying development of pest resistance to the insecticide, and the service lives of the chlorfenapyr and the neonicotinoid insecticides can be prolonged; dosage of the neonicotinoid insecticides can be reduced, and accordingly neonicotinoid insecticide residual risks can be reduced; the preparation in various dosage forms is made of the insecticide composition, and accordingly excellent prevention and control effects can be realized for the bradysia odoriphaga.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

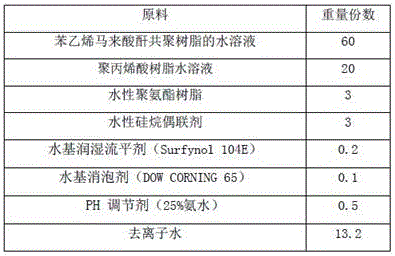

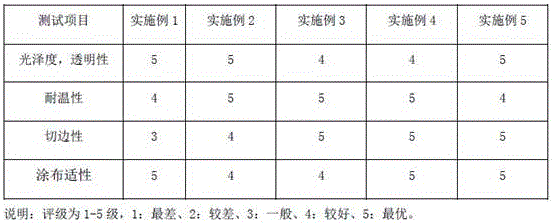

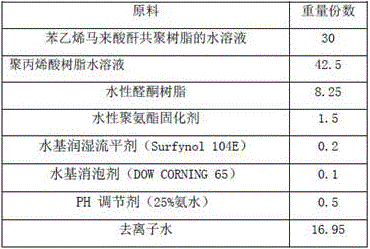

Water-based coloring layer coating for transfer film and preparation method of water-based coloring layer coating

The invention discloses a water-based coloring layer coating for a transfer film and a preparation method of the water-based coloring layer coating and particularly relates to a pure water-based coloring layer coating for a heat transfer film (alumite). The coating is prepared from, by mass, 20-60 parts of styrene-maleic anhydride polymerized resin water solution, 20-50 parts of polyacrylic resin water solution, 3-10 parts of water-based reinforced resin, 0-3 parts of water-based cross-linking agent, 0-1 part of water-based wetting leveling agent, 0-1 part of water-based defoamer, 0-1 part of PH modifier and 0-30 parts of deionized water. The styrene-maleic anhydride polymerized resin water solution and the polyacrylic resin water solution are prepared through a hydrothermal alkali dissolution method, and the product is prepared through a stirring and mixing method according to a feeding sequence. The product is purely based on water, environmentally friendly and safe, and can completely replace similar solvent type products on the market, and various properties are qualified through detection.

Owner:上海汉熵新材料科技股份有限公司 +1

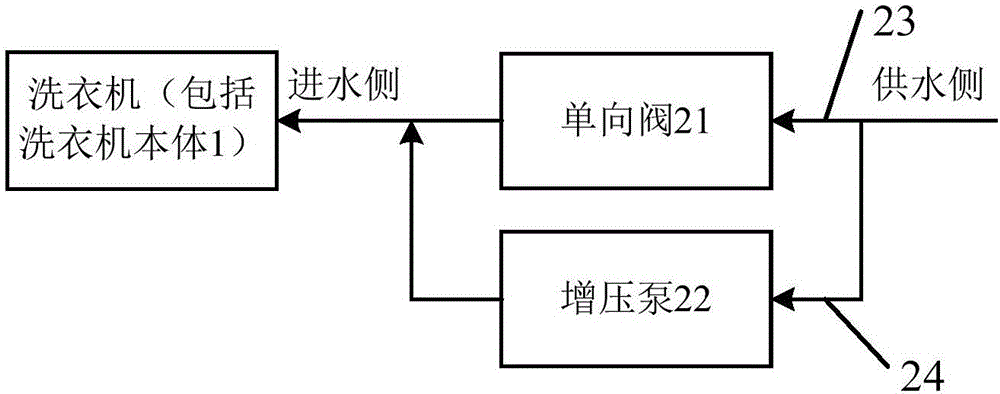

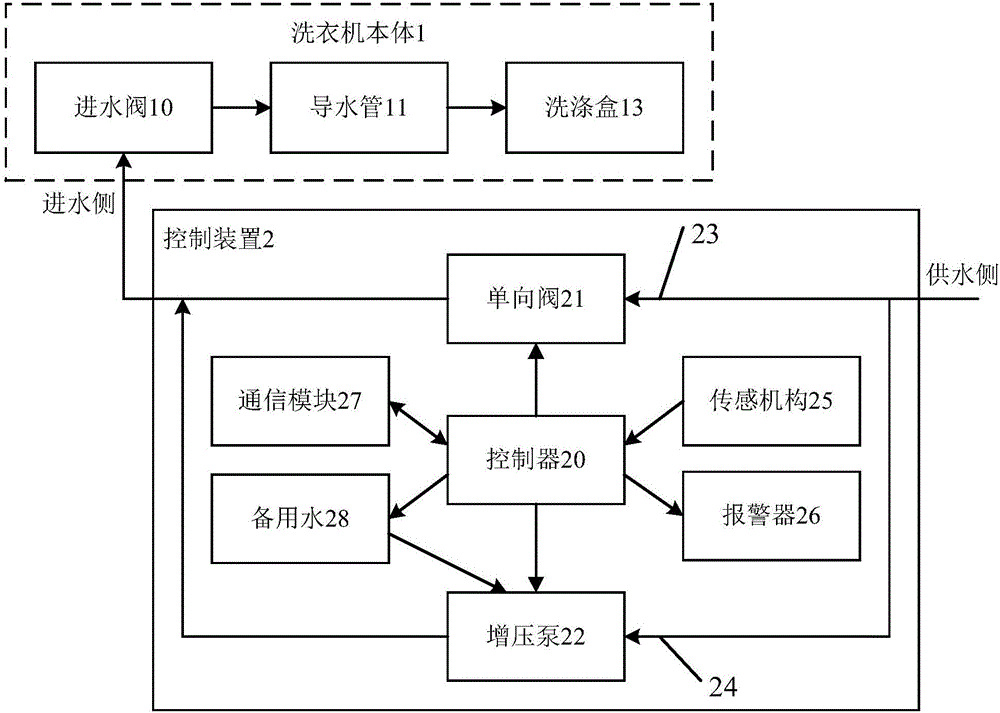

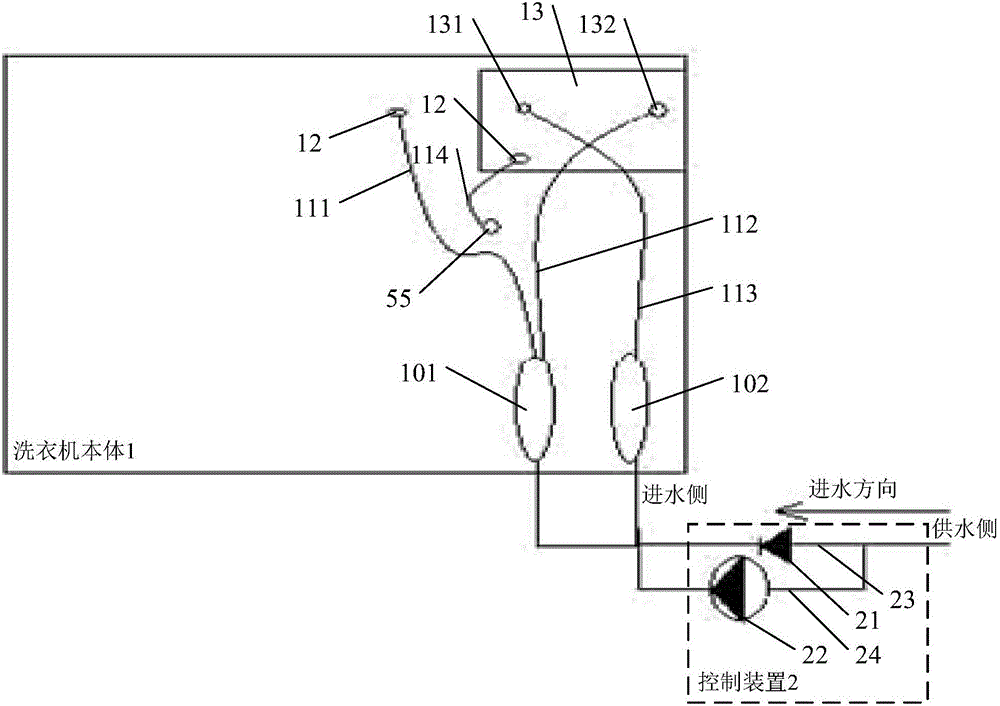

Control device and control method of washing machine and washing machine

ActiveCN106498667AEasy to useGuaranteed to rinse cleanOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

The invention discloses a control device and a control method of a washing machine and the washing machine. The control device comprises a one-way valve and a booster pump, wherein the one-way valve is adaptively arranged on a main water inlet pipeline of the washing machine and is used for causing water at the water supply side of the washing machine to be injected into the washing machine through the main water inlet pipeline so as to realize conventional water injection for the washing machine in a preset conventional mode; and the booster pump is adaptively arranged on a bypass water inlet pipeline of the main water inlet pipeline and is used for pressurizing water in the bypass water inlet pipeline and injecting the water into the washing machine under the reverse stop protection of the one-way valve so as to realize pressurized water replenishing for the washing machine in a preset emergency mode. According to the technical scheme, the control device and the control method of the washing machine and the washing machine have the beneficial effects that the defects of inconvenience in use, low reliability and poor user experience in the prior art can be overcome, and the beneficial effects of convenience in use, high reliability and good user experience are realized.

Owner:格力电器(成都)有限公司 +1

Natural nutrient capable of inhibiting harm of heavy metal and pesticide residue

InactiveCN103462020AIncrease nutritionImprove palatabilityFood preparationPesticide residueFreeze-drying

The invention relates to a natural nutrient capable of inhibiting the harm of heavy metal and pesticide residue. The natural nutrient is characterized by being prepared by the following steps: selecting peanut kernels, detoxified almond and walnut kernels, frying until the fragrance is generated, grinding to obtain mixed oily fine powder, and mixing the mixed oily fine powder with bean powder to obtain protein powder; selecting black sesame and ramie seeds, grinding into thick liquid, and carrying out continuous extraction by adopting a supercritical fluid, so as to obtain a mixed concentrated solution; selecting seaweed, edible mushrooms and the like, grinding into powder, and extracting to obtain a mixed concentrated solution; selecting purslane, green beans and the like, and carrying out fermentation to obtain a comprehensive fermentation liquor; selecting liquorice, and extracting to obtain an glycyrrhizic acid extracting solution; mixing, stirring uniformly, carrying out freeze drying, preparing into microparticles, sterilizing, and packaging, and thus the natural nutrient capable of inhibiting harm of heavy metal and pesticide residue is obtained.

Owner:王跃进

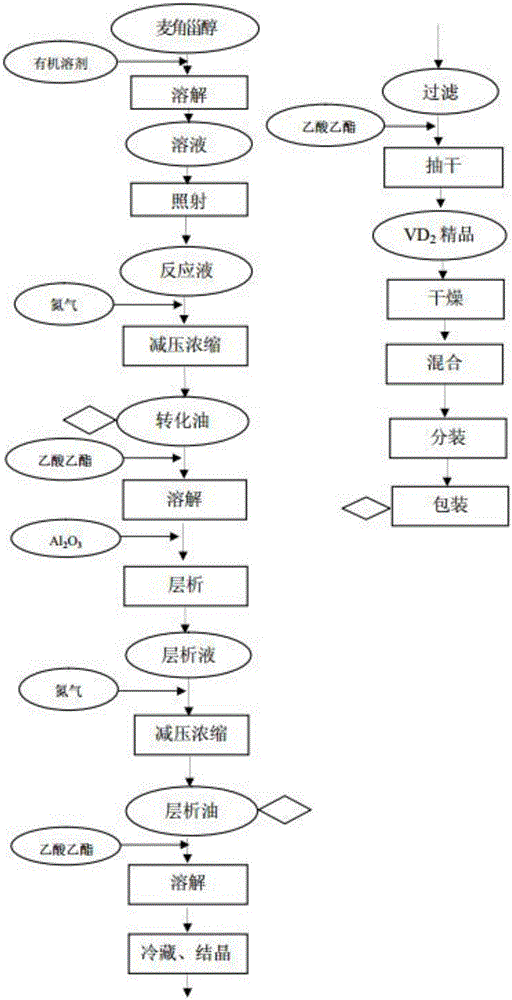

Production process of vitamin D2

ActiveCN106496088AHigh purityReduce by-product formationOrganic chemistryChemistryEnvironmental resistance

The invention discloses a production process of vitamin D2. The process includes the steps of: S1) light irradiation and thermal-isomerization reaction; S2) chromatographic eluting separation; S3) freezing crystallization separation; S4) drying, mixing and packaging. Compared with the prior art, the process is modified in synthetic process conditions, so that the process is improved in productivity and total yield of the product reaches more than 90%. The thermal-isomerization reaction and a pressure-reduced concentration step are combined, so that the process is simplified and is reduced in energy consumption. A synthesis reaction zone and a purifying separation zone are completely separated, so that process maintenance and process management are convenient. In addition, in the purifying process, a chromatographic crystallization method is employed directly instead of a process comprising chromatography, esterification and hydrolytic crystallization in the prior art, so that usage of toxic organic reagents is avoided, and the process is energy-saving, reduces consumption and is environment-friendly. In the production process of the vitamin D2, tail oil and tail materials contain lumisterol, tachysterol and other derivative products, so that it is valuable to deeply research and develop a high-value medicine intermediate.

Owner:SICHUAN YUXIN PHARM CO LTD

IQF (individual quick freezing) raw head-on prawn preservative and application thereof

InactiveCN105394160AImprove toughnessEnhanced crack resistanceMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsProtein proteinTrehalose

The invention provides an IQF (individual quick freezing) raw head-on prawn preservative and an application thereof. The preservative consists of the following raw materials in parts by weight: 20-25 parts of trehalose, 0.5-0.8 part of antioxidants of bamboo leaves, 1-1.6 parts of citric acid and 72.6-78.5 parts of aqueous extract of tremella. The preservative can effectively maintain the quality of the IQF raw head-on prawn and effectively prevent the problems such as blackening, fat oxidation, drying loss and protein freezing denaturation in the freezing preservation process; and the processing method is applicable to industrial continuous operation.

Owner:FUJIAN AGRI & FORESTRY UNIV

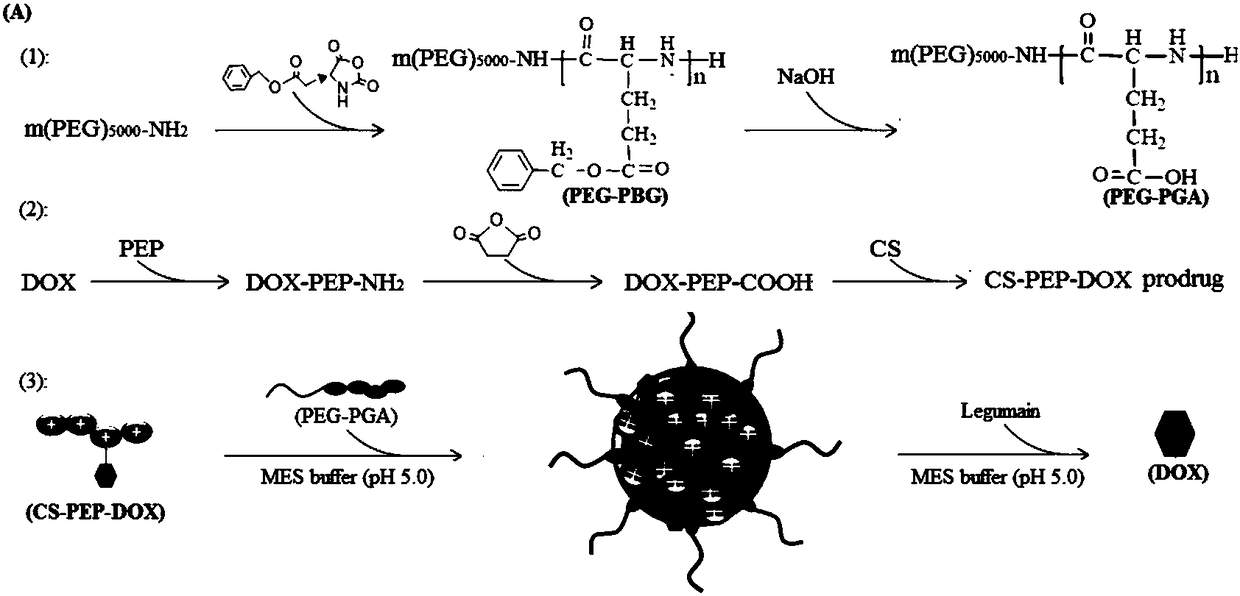

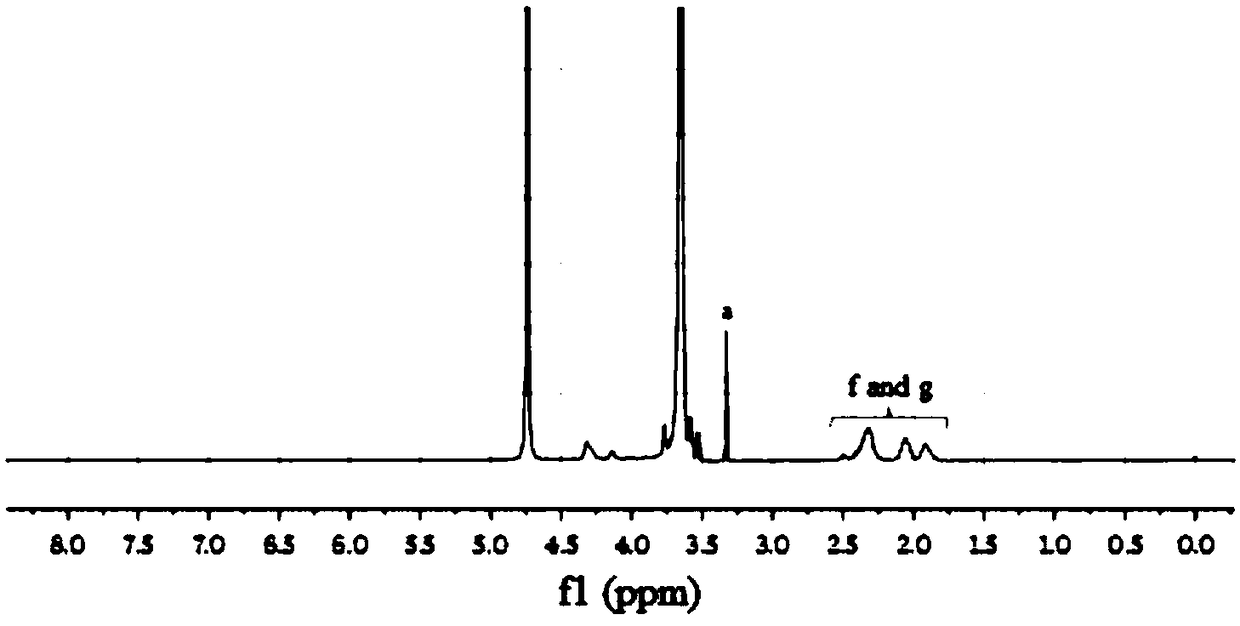

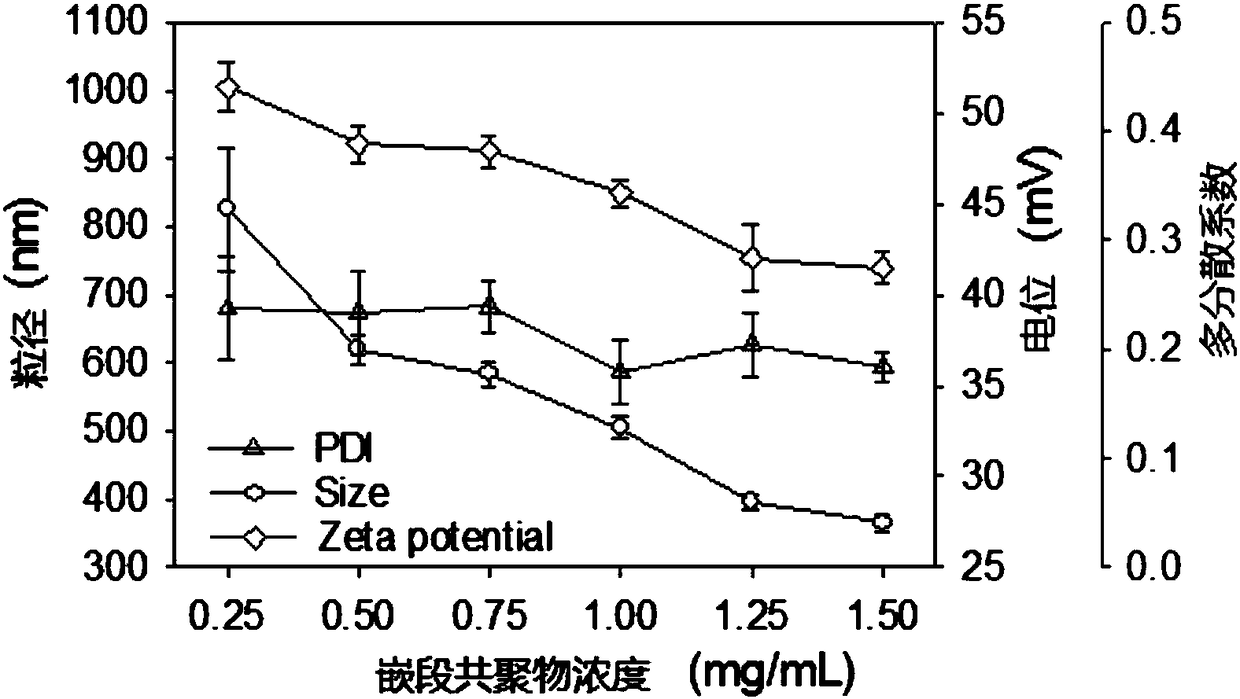

Method for preparing charge-driven self-assembled chitosan-based drug-loaded nanoparticles

ActiveCN108210932AReduce residual riskThe size is easy to controlOrganic active ingredientsGranular deliveryChitosan nanoparticlesBiocompatibility Testing

The invention discloses a method for preparing charge-driven self-assembled chitosan-based drug-loaded nanoparticles. The method comprises the following steps: (1) forming a PEG and benzyl polyglutamic acid block copolymer by PEG amino-induced benzyl glutamate-N-carbonyl cyclic anhydride, hydrolyzing the block copolymer under alkaline conditions to remove a benzyl at the benzyl polyglutamic acid end to form a PEG-PGA block copolymer; (2) preparing a chitosan-based doxorubicin prodrug; (4) preparing charge-driven self-assembled nanoparticles. The materials selected for the strategy for preparing the doxorubicin-based chitosan-based nanoparticles are PEG and PGA materials which are generally proved to have better biocompatibility, and the strategy for forming chitosan nanoparticles has better biocompatibility and biomedical prospects.

Owner:WENZHOU MEDICAL UNIV

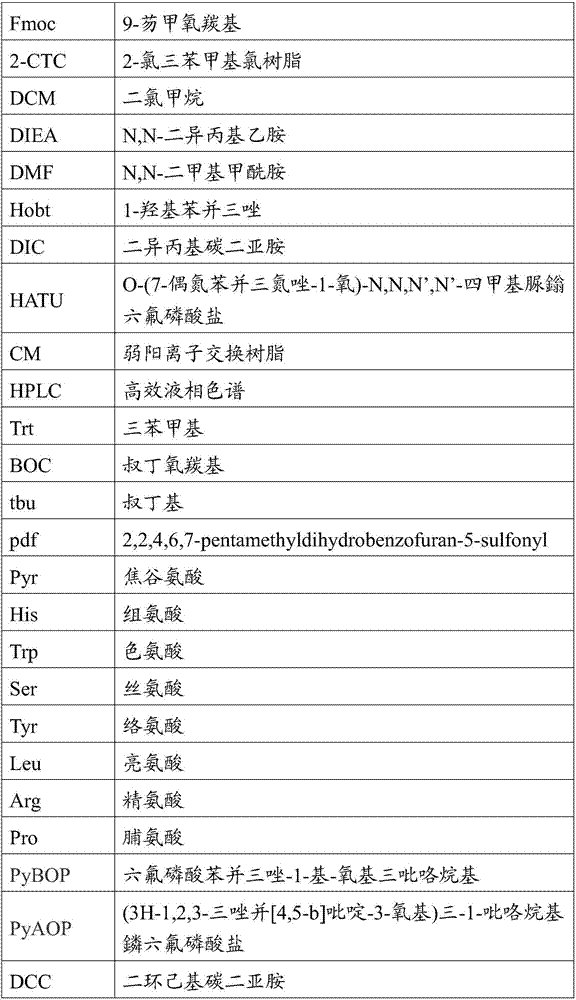

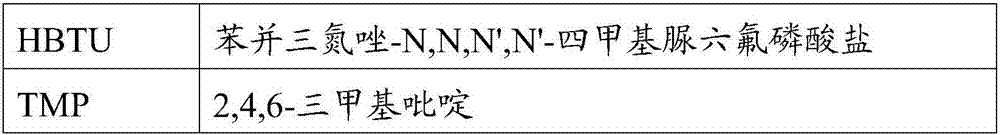

Synthesis method of high-purity leuprorelin

ActiveCN107573408AAvoid overly reactiveMild responseLuteinising hormone-releasing hormonePeptide preparation methodsSolid phasesSide chain

The invention provides a method for preparing leuprorelin. The method comprises the following steps: (1) taking Fmoc-Pro-CTC-OH and CTC (Carbon Tetrachloride) resin as starting raw materials and treating to obtain Fmoc-Pro-CTC-OH resin; (2) sequentially connecting the Fmoc-Pro-CTC-OH resin with an amino acid with a protecting group by adopting a gradual coupling manner of a Fmoc / tBu solid-phase method to synthesize side chain wholly-protected leuprorelin precursor peptide-resin; (3) taking a 20 percent trifluoroethanol / DCM (Dichloromethane) solution as a cutting reagent and cutting the side chain wholly-protected leuprorelin precursor peptide-resin, so as to obtain a side chain wholly-protected leuprorelin precursor peptide; (4) carrying out ethyl amination on the side chain wholly-protected leuprorelin precursor peptide to obtain side chain wholly-protected leuprorelin; (5) carrying out side chain cutting on the side chain wholly-protected leuprorelin to obtain a leuprorelin crude peptide; (6) carrying out CM purification and HPLC (High Performance Liquid Chromatography) purification, concentration, dissolving and freeze-drying on the leuprorelin crude peptide to obtain a high-purity leuprorelin crude drug. The method provided by the invention has the advantages of simplicity in operation, short period, low cost, high product yield and small environment pollution and is very suitable for industrial production.

Owner:上海丽珠制药有限公司

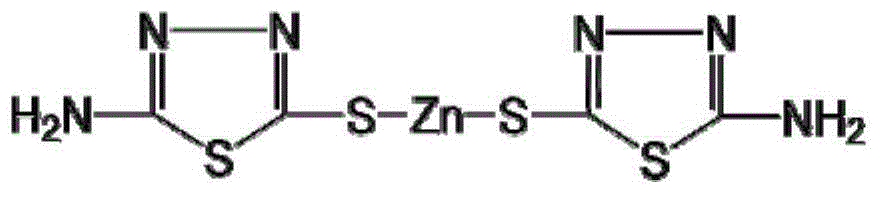

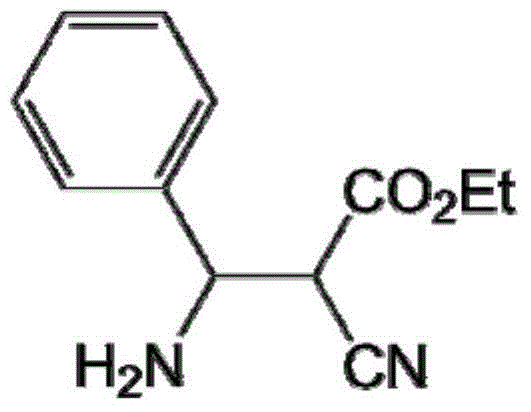

Agricultural composition containing zinc thiazole and phenamacril, and preparation and application thereof

The invention belongs to the field of pesticides, and relates to an agricultural composition, in particular to an agricultural composition containing zinc thiazole and phenamacril, and a preparation and application thereof. The agricultural composition containing zinc thiazole and phenamacril contains an effective component A and an effective component B; the effective component A is zinc thiazole; the effective component B is phenamacril; and the agricultural composition further contains an effective component C selected from any one of thiamethoxam, dinotefuran, tebuconazole and hymexazol. A dosage form prepared from the agricultural composition is capable of effectively delaying resistance and can be used for preventing and treating pathogenic bacteria, oomycete and fungal diseases of crops; the agricultural composition containing thiamethoxam or dinotefuran can also be used for preventing and treating diseases and insect pests simultaneously; and the agricultural composition disclosed by the invention is mainly used for processing crop seeds and soil, and has the advantages of being high in efficiency, low in toxicity and residual, good in environmental compatibility and low in cost.

Owner:ZHEJIANG XINNONG CHEM CO LTD

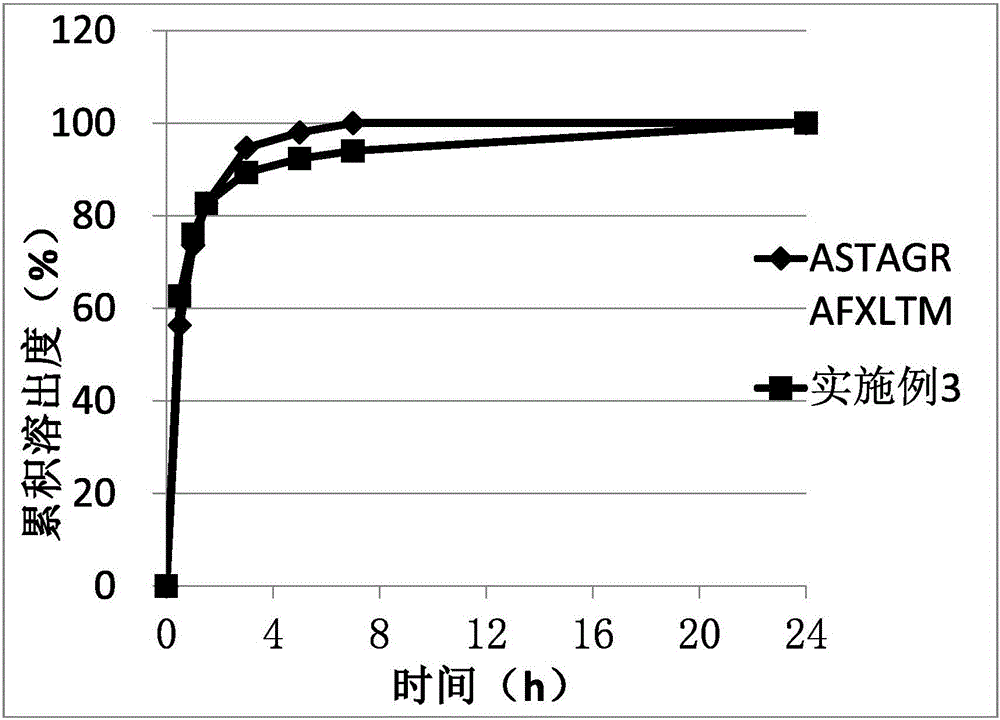

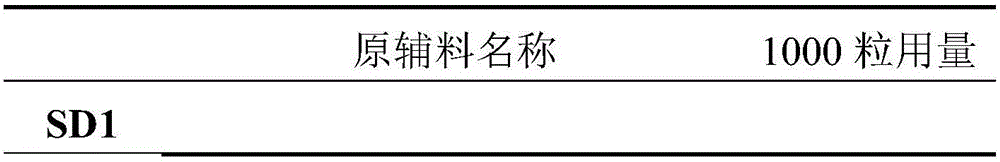

Sustained-release capsule containing tacrolimus solid dispersion and preparation method thereof

InactiveCN105663092AReduce the number of dosesImprove medication complianceOrganic active ingredientsPharmaceutical non-active ingredientsEthyl cellulosePharmaceutical preservatives

The invention belongs to the field of pharmaceutical preparations and particularly discloses a sustained-release capsule containing tacrolimus solid dispersion and a preparation method thereof. The sustained-release capsule contains 1 part by weight of tacrolimus, 0.6-6.0 parts by weight of polyvidone K30 and ethyl cellulose, lactose, excipient and lubricating agent. The sustained-release capsule containing tacrolimus solid dispersion is simple in preparation process, easy to reproduce and suitable for industrial popularization.

Owner:华益泰康药业股份有限公司

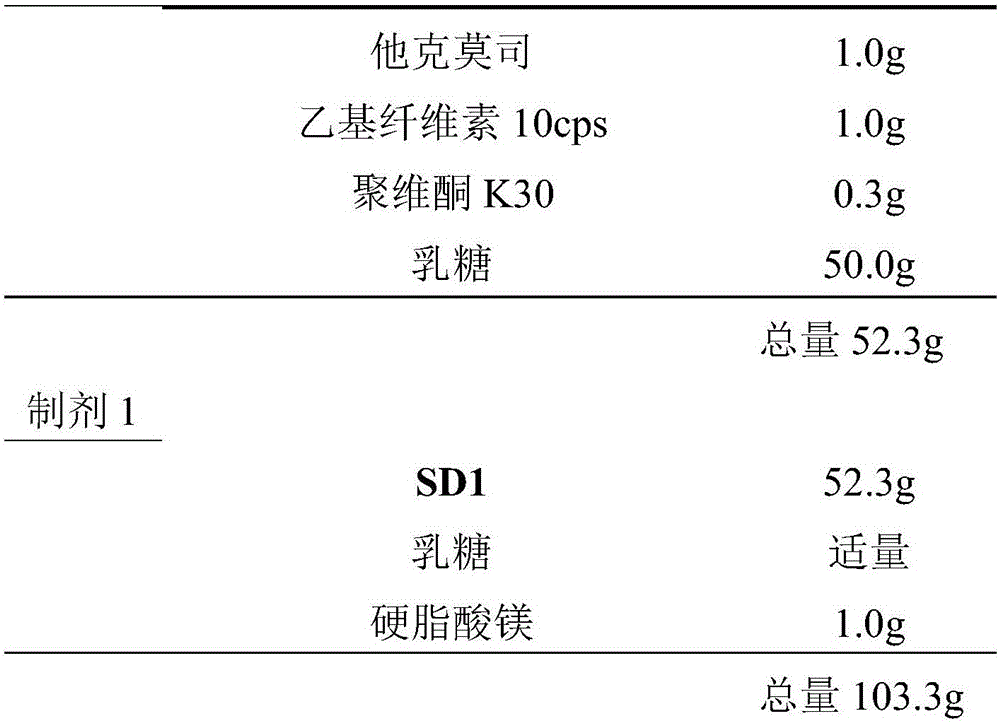

Chinese medicinal preparation for resisting coccidiosis and preparation method thereof

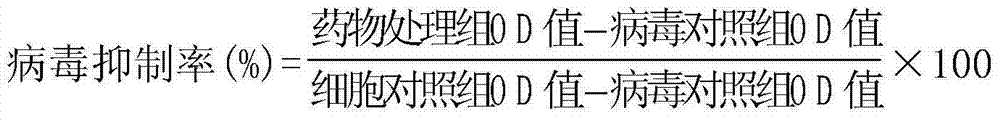

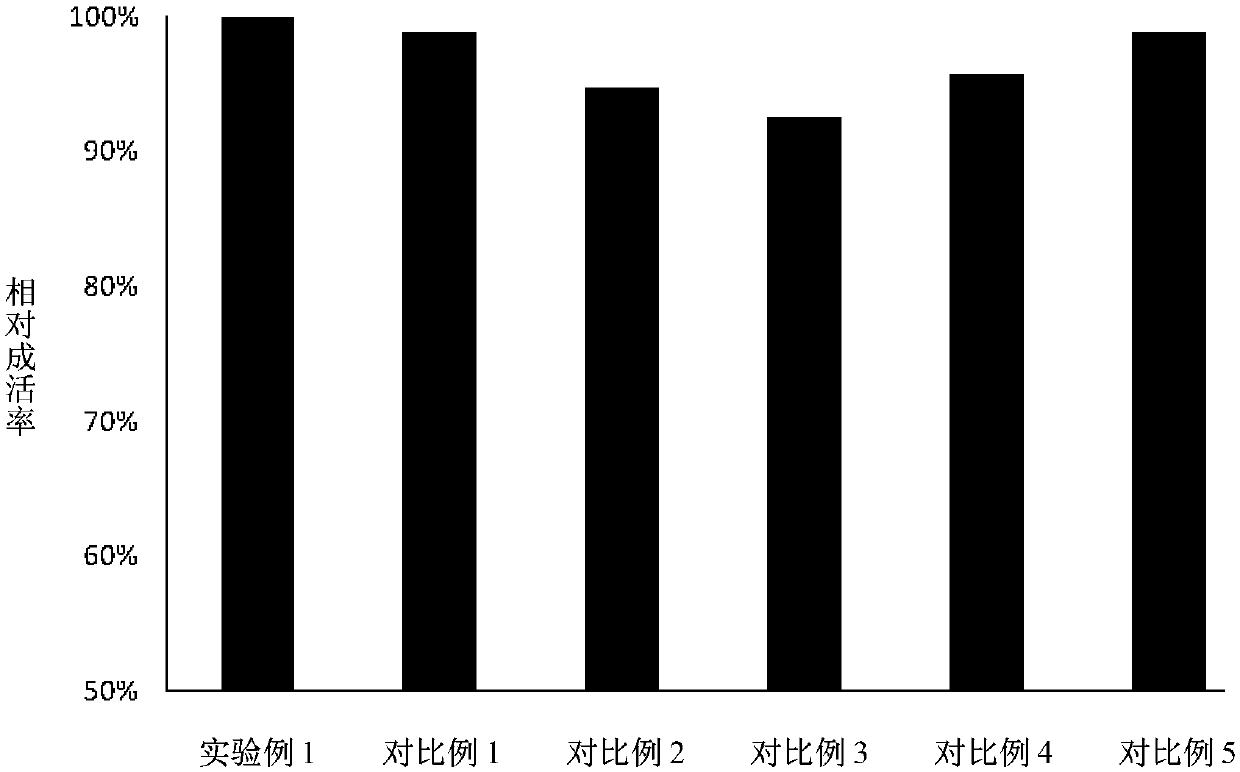

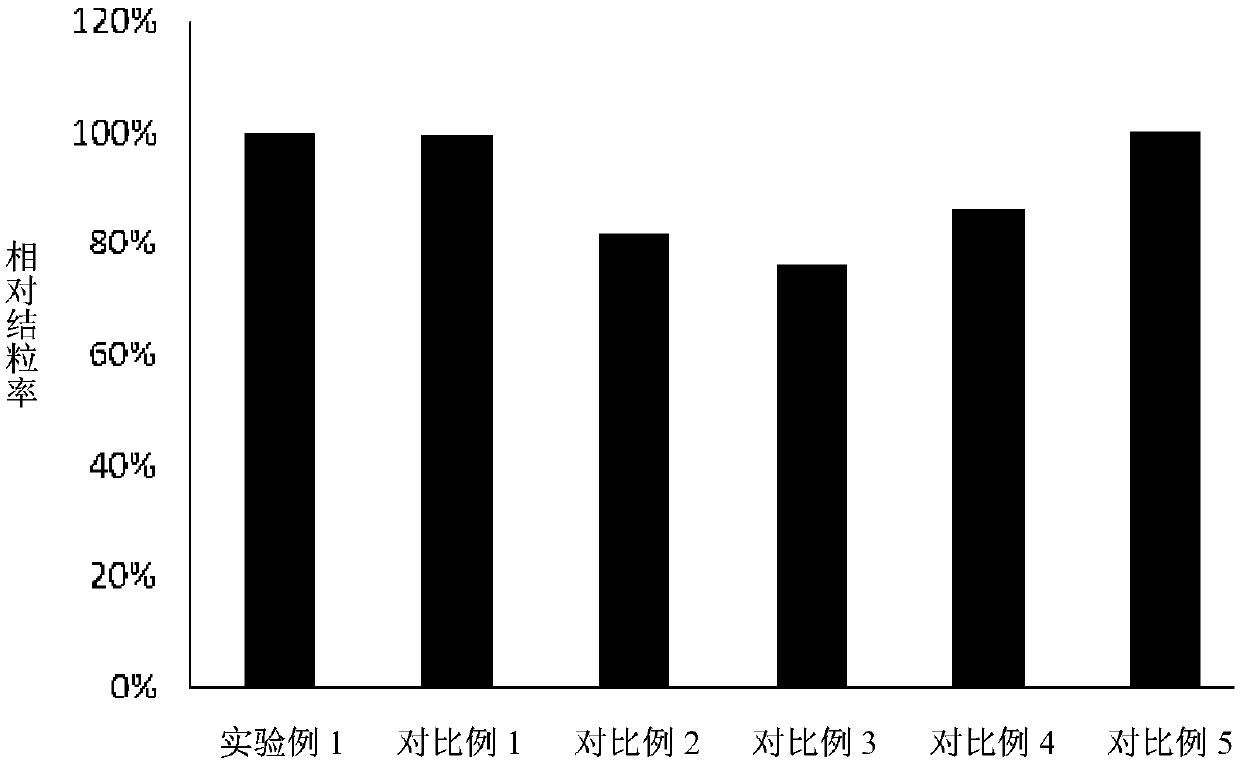

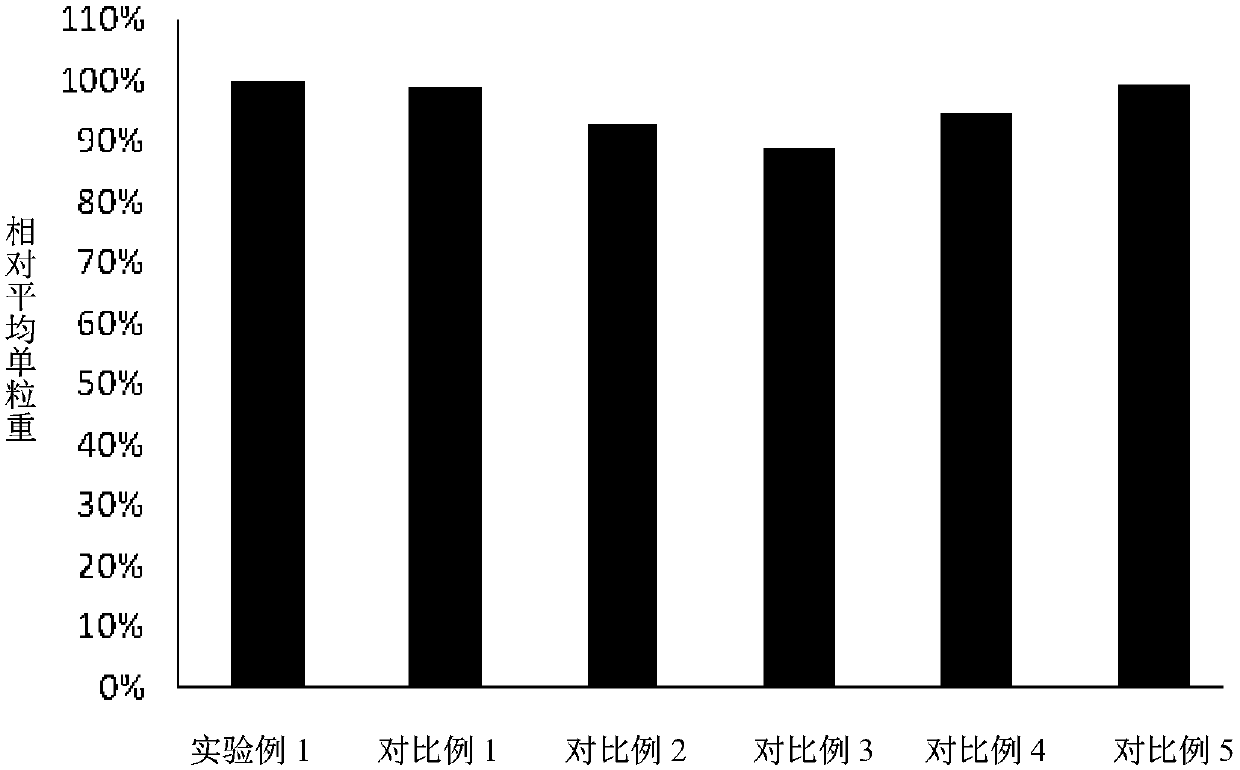

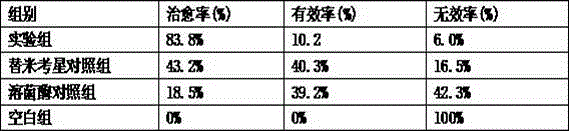

ActiveCN102988764AReduce the risk of drug residuesReduce residual riskAntiparasitic agentsPlant ingredientsCoccidiosisTraditional medicine

The invention discloses a Chinese medicinal preparation for resisting coccidiosis and a preparation method thereof. The Chinese medicinal preparation is prepared by extracting, concentrating and refining the following raw material drugs in parts by weight: 2 to 10 parts of Chinese rhubarb, 1 to 10 parts of common bletilla pseudobulb, 1 to 10 parts of garden burnet, and 2 to 10 parts of hairyvein agrimony. According to the Chinese medicinal preparation for resisting coccidiosis and the preparation method thereof, the preparation is prepared by extracting, concentrating and preparing the Chinese medicinal drugs, has the effects of clearing heat and cooling blood, and astringing to stop bleeding, and is used for treating bloody stools caused by coccidiosis; and the Chinese medicinal preparation is simple in preparation and high in safety, and convenient to drink (mixed drinking with 2.5 to 5g for each chick), cannot cause drug resistance, and is advantageous to treatment of coccidiosis.

Owner:XIAN CHANGSHENG ANIMAL HEALTH PRODS

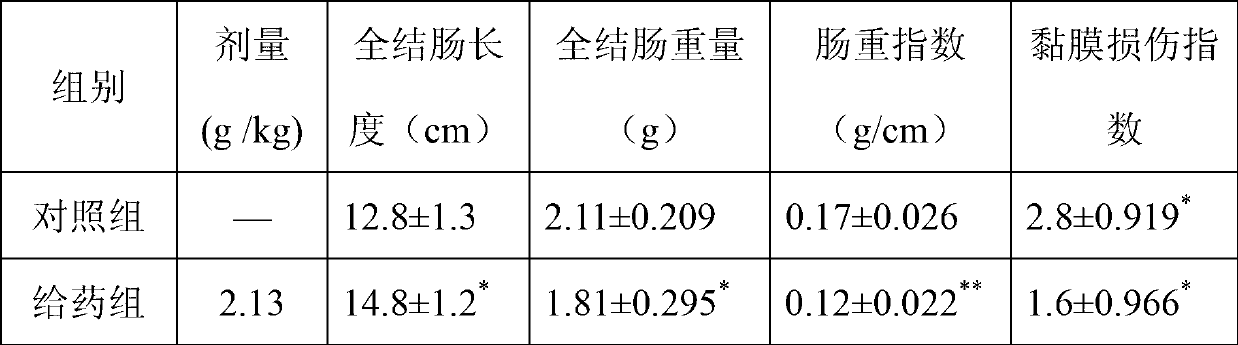

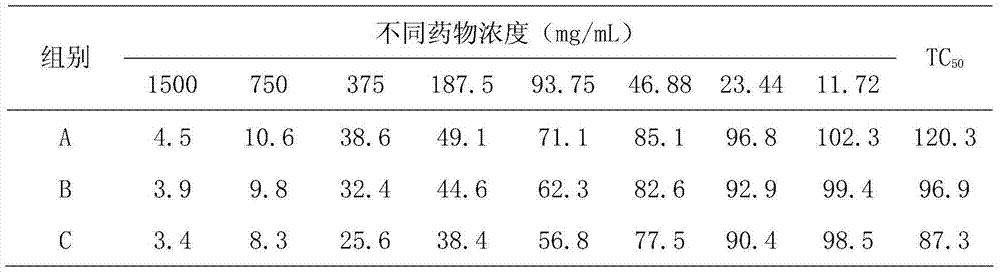

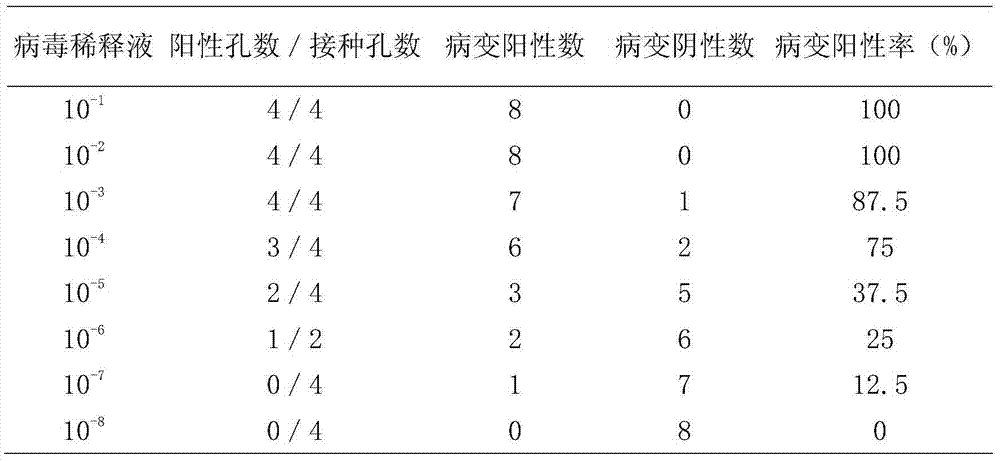

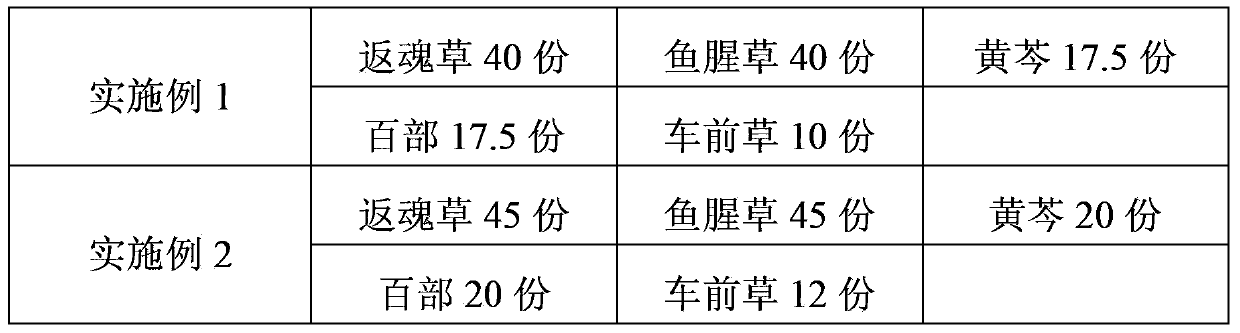

Veterinary antiviral traditional Chinese medicine Ziqi effervescent granules and preparation method thereof

InactiveCN103768157ACurb spreadInhibited DiffusionAntibacterial agentsAntiviralsDiseaseVeterinary Drugs

The invention belongs to the technical field of traditional Chinese medicinal veterinary drugs, and discloses a veterinary antiviral traditional Chinese medicine Ziqi effervescent granules and a preparation method thereof. The medicine is prepared from the following raw materials in parts by weight: 30-50 parts of Echinacea purpurea, 30-45 parts of Astragalus membranaceus, 10-25 parts of Scutellaria baicalensis, 10-25 parts of Flos Lonicerae, and 5-15 parts of Forsythia suspense. The medicine is used for preventing and treating Newcastle disease and infectious bursal disease of poultry, and effectively inhibiting spread and diffusion of bacterial and viral diseases of livestock and poultry. The medicine has medicament and nutritional agent dual functions, and can be used as an immunopotentiator and immunostimulant to enhance the immunity of livestock and poultry and improve the disease resistance.

Owner:陕西冠嘉高科生物技术有限公司

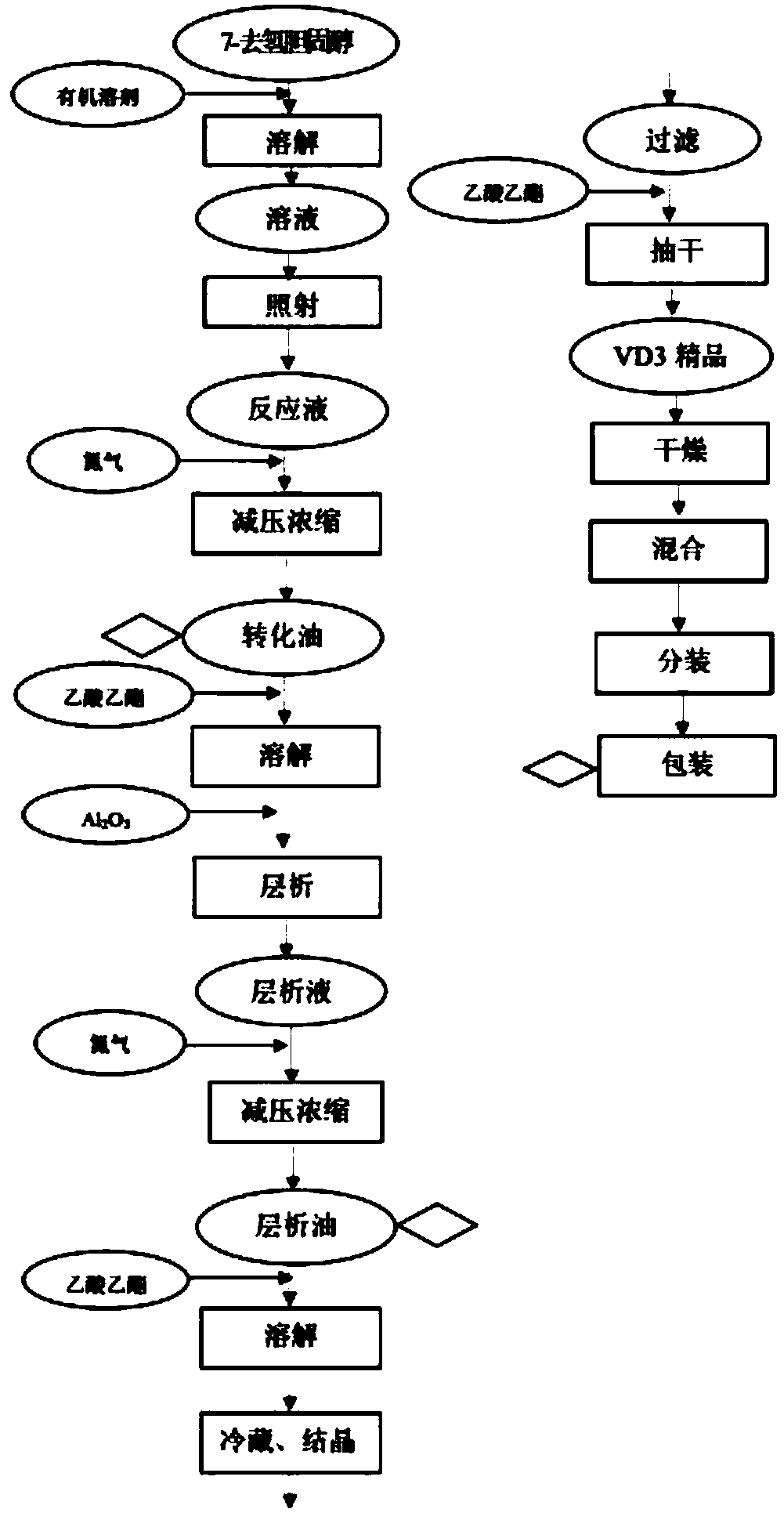

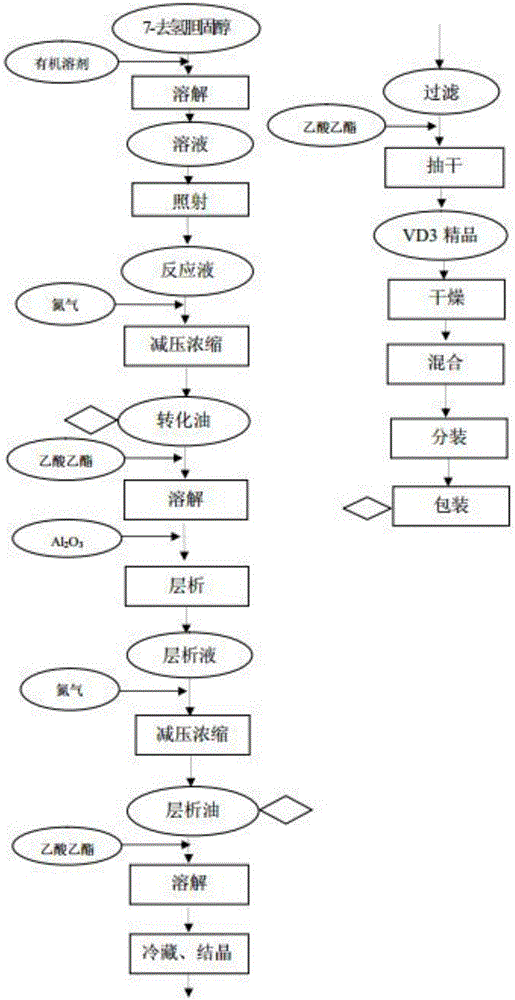

A kind of production technology of vitamin d3

ActiveCN106478479BReduce residual riskEmission reductionOrganic chemistryChemical industryIsomerizationHydrolysis

The invention discloses a vitamin D3 production process, which comprises: S1, light irradiation and thermal isomerization reaction; S2, chromatography elution separation; S3, refrigeration crystallization separation; and S4, drying mixing sub-packing. Compared to the process in the prior art, the process of the present invention has the following characteristics that the synthesis process conditions are improved, such that the productivity of the process is improved, and the total yield of the product is more than 90%; the thermal isomerization reaction of the vitamin D3 and the pressure reducing concentration are combined so as to simplify the process steps and save the process energy consumption; the synthesis reaction zone and the purification separation zone are completely separated so as to easily perform process maintenance and process management; in the purification process, the chromatography crystallization method is directly used to replace the original process of chromatography, esterification and hydrolysis crystallization, such that the use of the toxic organic reagent is avoided, and the effects of energy saving, consumption reducing and environmental protection are achieved; and the tail oil tailings generated during the vitamin D3 series production process can be adopted as the feed additive resource so as to be used.

Owner:SICHUAN YUXIN PHARM CO LTD

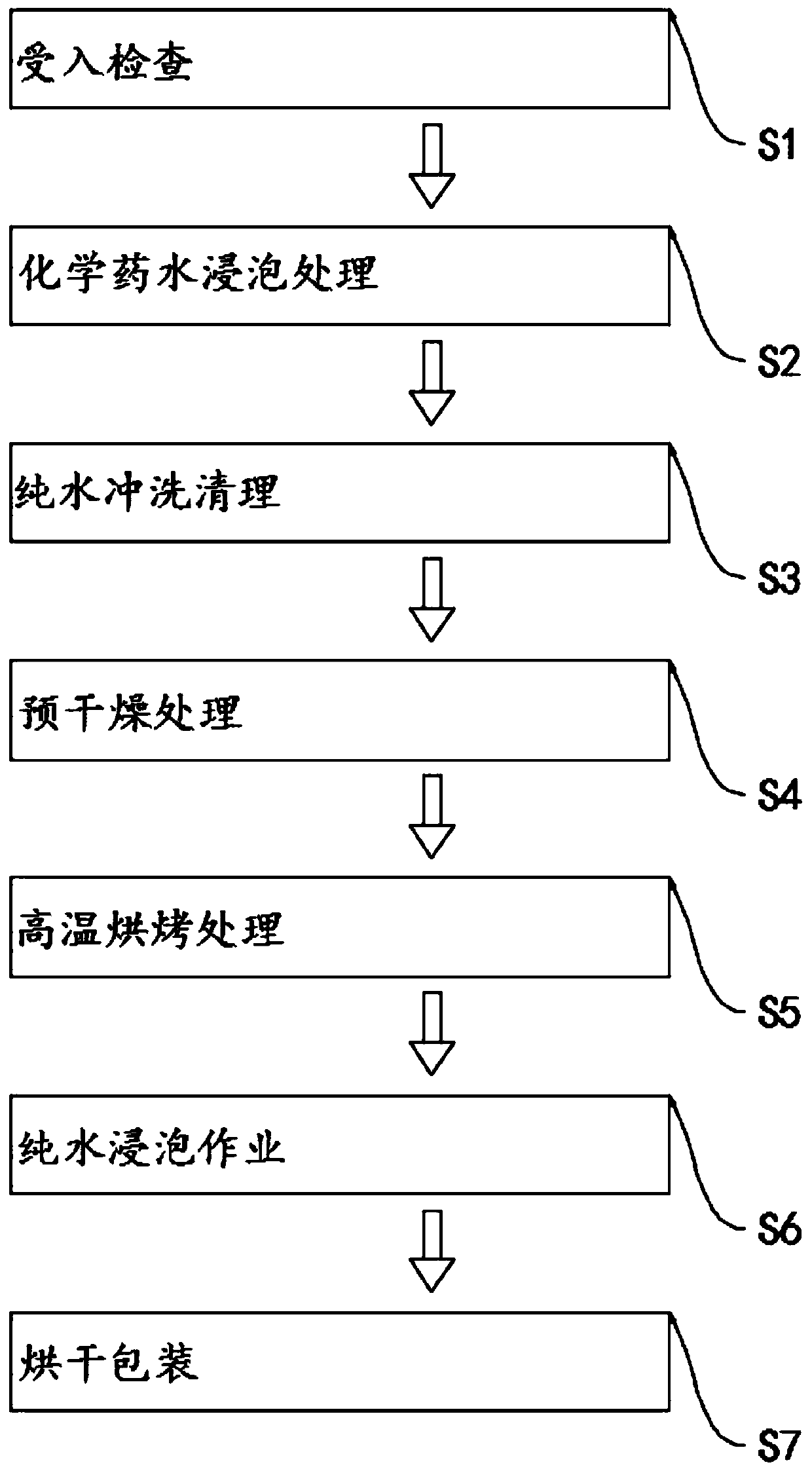

Cleaning and regenerating method of titanium crucible

InactiveCN111482423ASimplify the cleaning processReduce wash timeDrying solid materials without heatHollow article cleaningSurface moistureTitanium

The invention discloses a cleaning and regenerating method of a titanium crucible, and relates to the technical field of OLED panel production. The method comprises the following steps of receiving inspection, wherein integrity inspection is carried out on a titanium crucible body, and the residual amount of a film layer is determined; soaking treatment with chemical liquid; pure water flushing and cleaning, wherein the titanium crucible body soaked with the liquid is flushed with pure water, and floating ash and impurities on the surface of the crucible are removed; pre-drying treatment, wherein an air gun is used for blowing the surface of the titanium crucible body flushed with the pure water, surface moisture is removed, and the titanium crucible body is placed in a drying box to be dried; high-temperature baking treatment, wherein the titanium crucible body subjected to pre-drying treatment is subjected to high-temperature baking treatment; pure water soaking operation, wherein the titanium crucible body subjected to high-temperature baking treatment is placed in pure water to be soaked; and drying and packaging, wherein the titanium crucible body soaked with the pure water isdried and packaged for use. The method has the advantages that the crucible residual film is effectively cleaned, and meanwhile the crucible loss is reduced.

Owner:四川富乐德科技发展有限公司

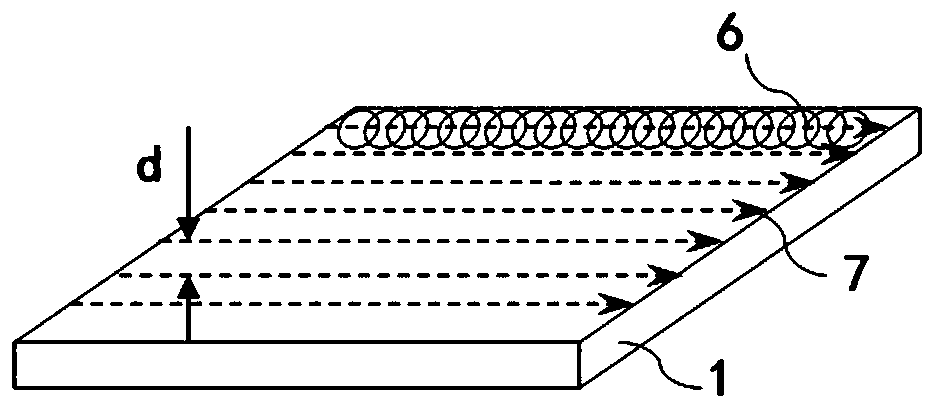

Method for improving adhesive force between metal film layer and high-dielectric-constant ceramic substrate

ActiveCN110729173AImprove uniformityReduce defectsSemiconductor/solid-state device manufacturingThin membraneIntegrated circuit

The invention relates to a method for improving an adhesive force between a metal film layer and a high-dielectric-constant ceramic substrate and belongs to the technical field of fine processing of microwave integrated circuits. According to the method, array scribing type etching roughening treatment is performed on the surface layer of a substrate by adopting ultraviolet laser with specific performance; high-temperature calcination is performed on the coarsened substrate under a high-temperature condition on the basis of a specific temperature curve, so that the roughness Ra value of the surface of the substrate is stabilized within the range of 0.25-0.3 mm, and good roughening uniformity is achieved; and the adhesive force between the metal film layer and the high-dielectric-constant substrate which serves as a base material in the process of manufacturing a microwave integrated thin film circuit.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Drug for treating chicken airsacculitis and preparation method of drug

InactiveCN103417884AAntiviralAntibacterialAntibacterial agentsAntipyreticSenecio cannabifoliusAntibiotic Y

The invention discloses drug for treating chicken airsacculitis. The drug is made from the following raw materials by weight: 30-50 parts of senecio cannabifolius less, 30-50 parts of houttuynia cordata, 10-25 parts of scutellaria baicalensis, 10-25 parts of radix stemonae and 5-15 parts of plantain herb. The drug is a preparation purely made form traditional Chinese medicine, has the effects of antibiosis, inflammation resistance and diarrhea checking, and can be used for treating and preventing the chicken airsacculitis. Compared with antibiotics which are used for treating the chicken airsacculitis and produce drug residue and drug resistance, the drug has the advantages that the security is improved remarkably and the effects are definite. Through the popularization and application of the drug, the risks of drug residue in poultry products and egg products can be effectively reduced.

Owner:陕西冠嘉高科生物技术有限公司

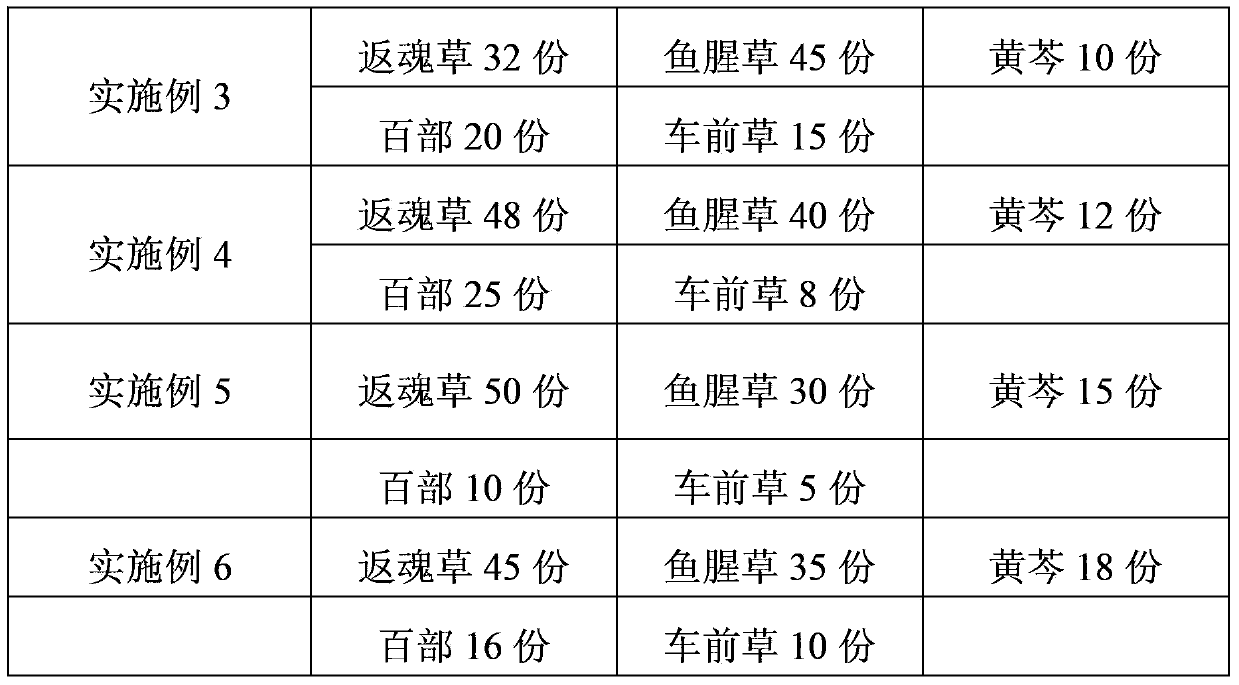

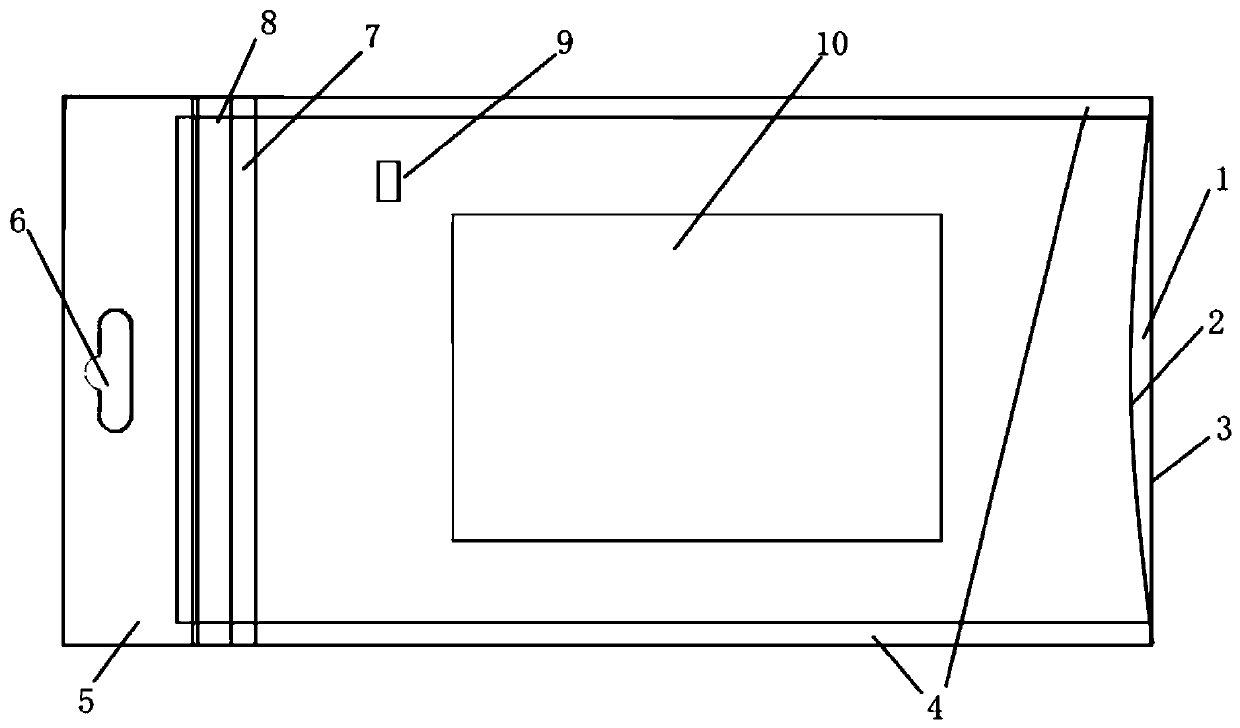

Sterilizing mask bag capable of being repeatedly opened and sealed

PendingCN111348316AReduce residual riskIncrease costBagsSacksEthylene Oxide SterilizationBiomedical engineering

The invention discloses a sterilizing mask bag capable of being repeatedly opened and sealed. The sterilizing mask bag is formed by sealing burning of medical dialyzing paper and a plastic composite film. The three edges of the plastic composite film and the three edges of the medical dialyzing paper are aligned for sealing burning. The other edge of the plastic composite film protrudes and extends out of the medical dialyzing paper and is folded towards the medical dialyzing paper side, and a folding part is formed. An object taking port capable of being repeatedly opened and sealed is formedby the plastic composite film and the medical dialyzing paper at the end close to the folding part. An ethylene oxide sterilizing indication mark is printed on the medical dialyzing paper. Accordingto the sterilizing mask bag, the sterilizing mask bag is provided and is capable of being repeatedly opened and sealed and containing multiple masks at the same time, the package cost is reduced, hanging is convenient, ethylene oxide sterilizing can be conducted, and the ethylene oxide residue risk after sterilization is reduced.

Owner:SHANGHAI JIANZHONG MEDICAL PACKAGING

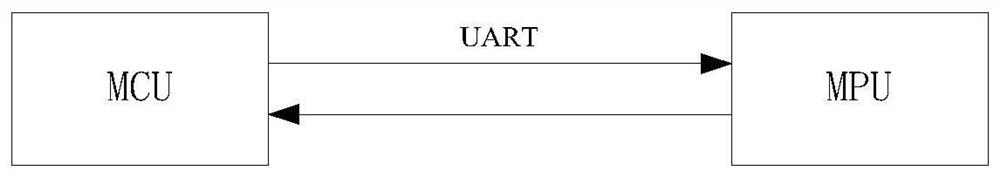

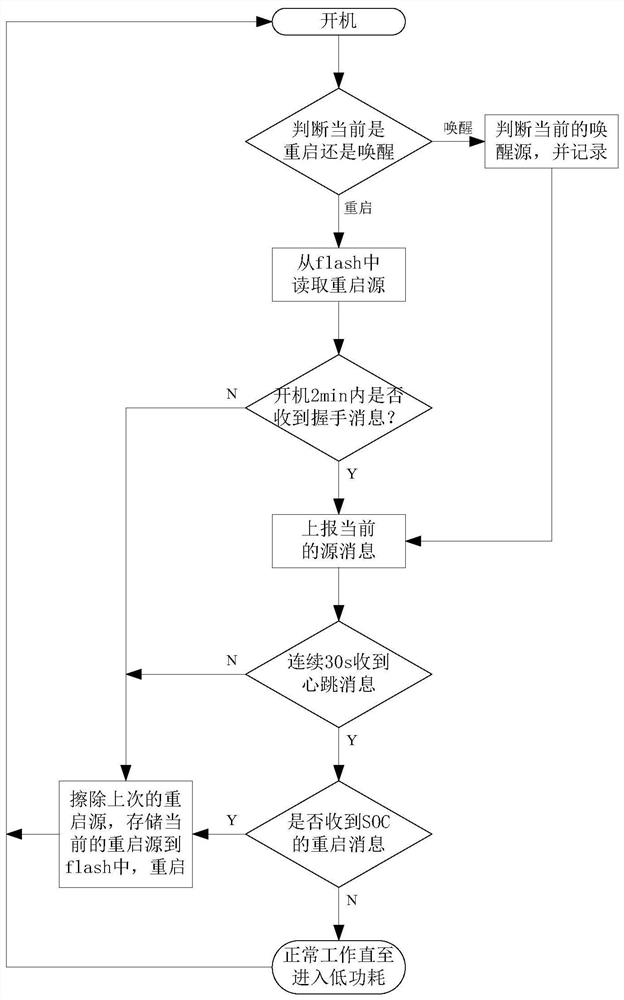

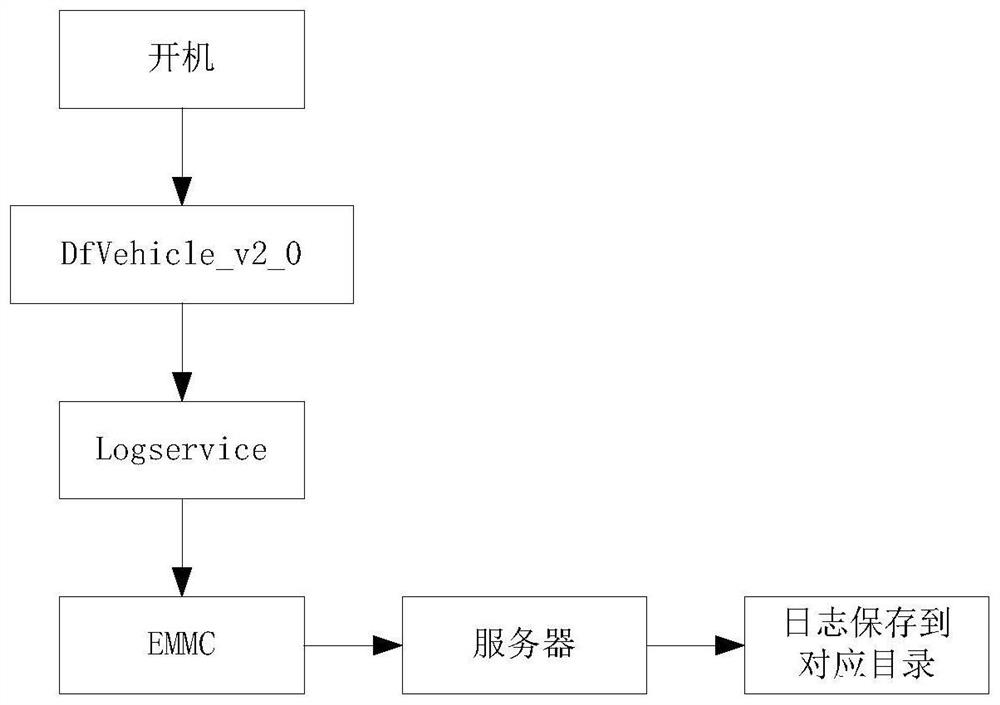

Vehicle-mounted entertainment system restart fault diagnosis method and system

ActiveCN112860466AImprove fault diagnosis efficiencyImprove accuracyFault responseSpecial data processing applicationsIn vehicleDirectory

According to the vehicle-mounted entertainment system restart fault diagnosis method and system provided by the invention, the reasons of MPU restart are recorded through the MCU, the reasons are automatically packaged and uploaded to the log server at the rear end through the Android system, and the functions of automatically storing logs in corresponding directories, automatically classifying problems and the like are achieved according to the information of uniquely identifying the vehicle; and the efficiency and the accuracy of fault diagnosis are improved. According to the invention, through providing a set of complete fault positioning system, various problems encountered in the actual operation process of the vehicle, especially problems which are not easy to reproduce, are quickly and efficiently positioned, the analysis efficiency is greatly improved, the problem leaving risk is reduced, and the user experience is improved. Developers can check logs of related time points in corresponding directories, and the developers can conveniently and visually know fault types of vehicles and analyze problems.

Owner:DONGFENG MOTOR CORP HUBEI

Preparing and using methods of composting fermentation strain

ActiveCN107974409ALow costEasy to operateBio-organic fraction processingMicroorganismsBiotechnologyDecomposition

The invention relates to a preparing method of a composting fermentation strain. Preparing and using methods comprise the following steps: collecting microorganisms in an environment; inoculating a selective medium, which takes a rice leachate, sugar, milk, inorganic salt, bran, rice husks, composting raw material chippings as major ingredients, with the microorganisms, and implementing directional screening and propagation, so that the compound strain which is applicable to composting is obtained; forming a trapezoid material pile by virtue of such composting raw materials as crop straws, vegetable leavings, excrements of livestock, kitchen waste and the like; regulating the trapezoid material pile to a proper water content; uniformly inoculating the trapezoid material pile with the composting fermentation strain; turning the pile for several times and implementing aerobic fermentation until composting raw materials become soft, the volume of the composting raw materials is diminished, the morphology of the raw materials cannot be observed obviously, and the composting raw materials are neutral or faintly alkaline and free from odor, so that composting is completed. With the application of the methods, composting time can be obviously shortened, the thorough decomposition of the composting raw materials can be accelerated and a more thorough fermentation reaction can be guaranteed.

Owner:王永显

Organic fertilizer with insecticidal effect

ActiveCN107827491AImprove water holding capacityIncrease water contentBio-organic fraction processingExcrement fertilisersElaeagnus angustifoliaSolanum tuberosum

The invention belongs to the technical field of potato breeding, and in particular relates to an organic fertilizer which has an insecticidal effect and is used for producing breeder seeds of potatoes. The organic fertilizer is formed by fermentation of sophora alopecuroides, selenium sand watermelon vines, waste selenium sand watermelons, Chinese wolfberry branches and leaves, purslane herb, kochia scoparia, elaeagnus angustifolia processing waste, waste vinasse, plant ash, 10-20 parts of manure, a solid culture medium and a fermentation agent. The fertilizer provided by the invention can effectively reduce the use amount of a pesticide by 25-35%.

Owner:固原天启薯业有限公司

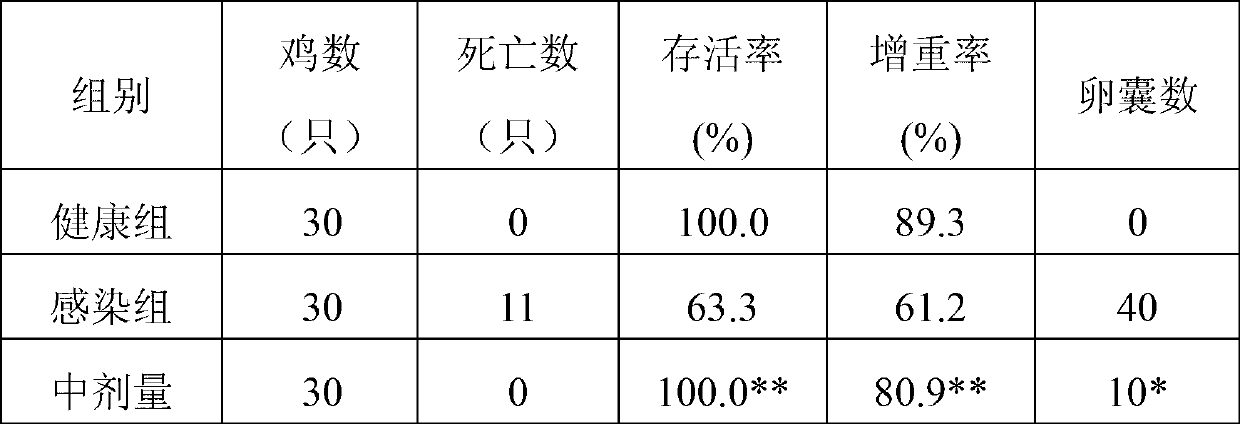

Compound tilmicosin solid dispersing agent and preparation method thereof

InactiveCN106620668AAvoid damageGood curative effectAntibacterial agentsOrganic active ingredientsEudragit LIrritation

The invention discloses a compound tilmicosin solid dispersing agent and a preparation method thereof. The compound tilmicosin solid dispersing agent comprises, by weight percentage, 1.0-2.0% of Eudragit L-100, 0.2-0.5% of sodium bisulfite, 10-30% of tilmicosin, 0.5-1% of lysozyme, 0.5-1% of aesculetin, 2-5% of polyvidone and the balance anhydrous dextrose. The solid dispersing agent prepared by the method has the advantages that the medicine effect of the tilmicosin is kept, bioavailability is increased evidently, good palatability is achieved, gastrointestinal tract irritation is avoided, cure rate can be increased greatly, controlled-release absorption is formed in the intestinal tract, plasma concentration is kept at the therapeutic dose for a long time, and the highest medicine utilization rate is achieved; in addition, the dispersing agent has an immunoregulation function and can recover macrophage immune activity.

Owner:WUHAN XINLIANDA BIOLOGY

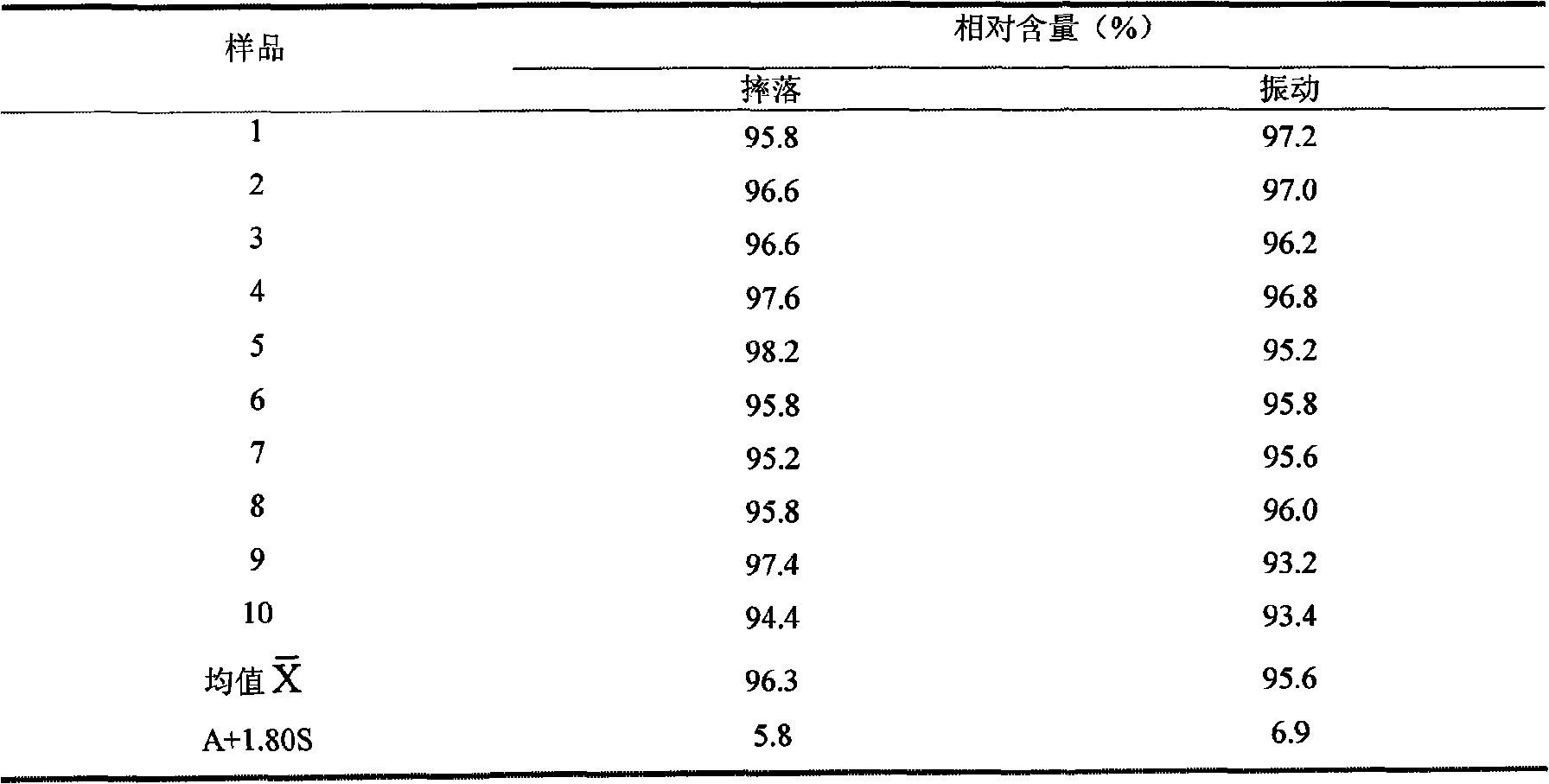

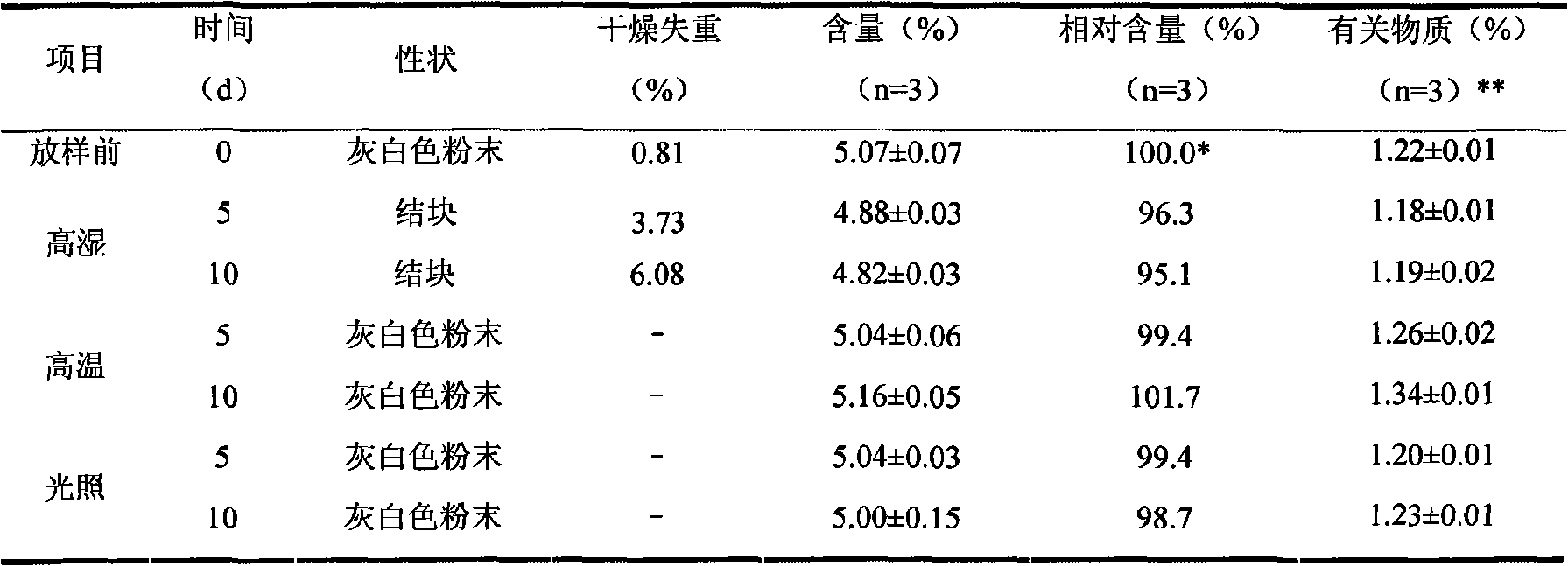

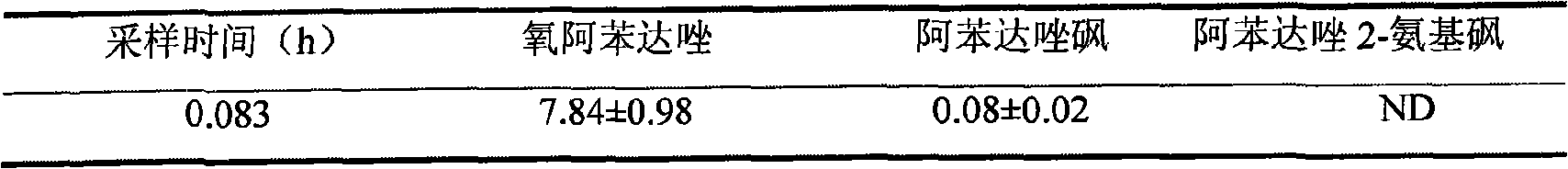

Albendazole oxide hydrochloride premix for animals

InactiveCN101536983AImprove stabilityLow hygroscopicityPowder deliveryOrganic active ingredientsBiotechnologyAnimal science

The invention belongs to the application technical field of medical feed additives, more particularly relates to preparation and application of an albendazole oxide hydrochloride premix for animals. In the premix, the albendazole oxide hydrochloride is taken as an active ingredient which is evenly mixed with a carrier zeolite powder to obtain the premix. The premix consists of the following parts of materials by weight: 1-20 parts of the albendazole oxide hydrochloride with less than 1% of water and 80-90 parts of the zeolite powder with less than 1% of water which are mixed to obtain a finished product by a conventional method. The premix prepared by the invention can be added to a compound feed for pigs, sheep and cattle for preventing parasitic diseases in animals. Administration dose is 5-10mg per kilogram of body weight based on the active ingredient. The premix prepared by the invention has the advantages of good performance, high bioavailability and quick residue elimination.

Owner:HUAZHONG AGRI UNIV

Vitamin D3 production process

ActiveCN106478479AHigh purityReduce generationOrganic chemistryChemical industryIsomerizationHydrolysis

The invention discloses a vitamin D3 production process, which comprises: S1, light irradiation and thermal isomerization reaction; S2, chromatography elution separation; S3, refrigeration crystallization separation; and S4, drying mixing sub-packing. Compared to the process in the prior art, the process of the present invention has the following characteristics that the synthesis process conditions are improved, such that the productivity of the process is improved, and the total yield of the product is more than 90%; the thermal isomerization reaction of the vitamin D3 and the pressure reducing concentration are combined so as to simplify the process steps and save the process energy consumption; the synthesis reaction zone and the purification separation zone are completely separated so as to easily perform process maintenance and process management; in the purification process, the chromatography crystallization method is directly used to replace the original process of chromatography, esterification and hydrolysis crystallization, such that the use of the toxic organic reagent is avoided, and the effects of energy saving, consumption reducing and environmental protection are achieved; and the tail oil tailings generated during the vitamin D3 series production process can be adopted as the feed additive resource so as to be used.

Owner:SICHUAN YUXIN PHARM CO LTD

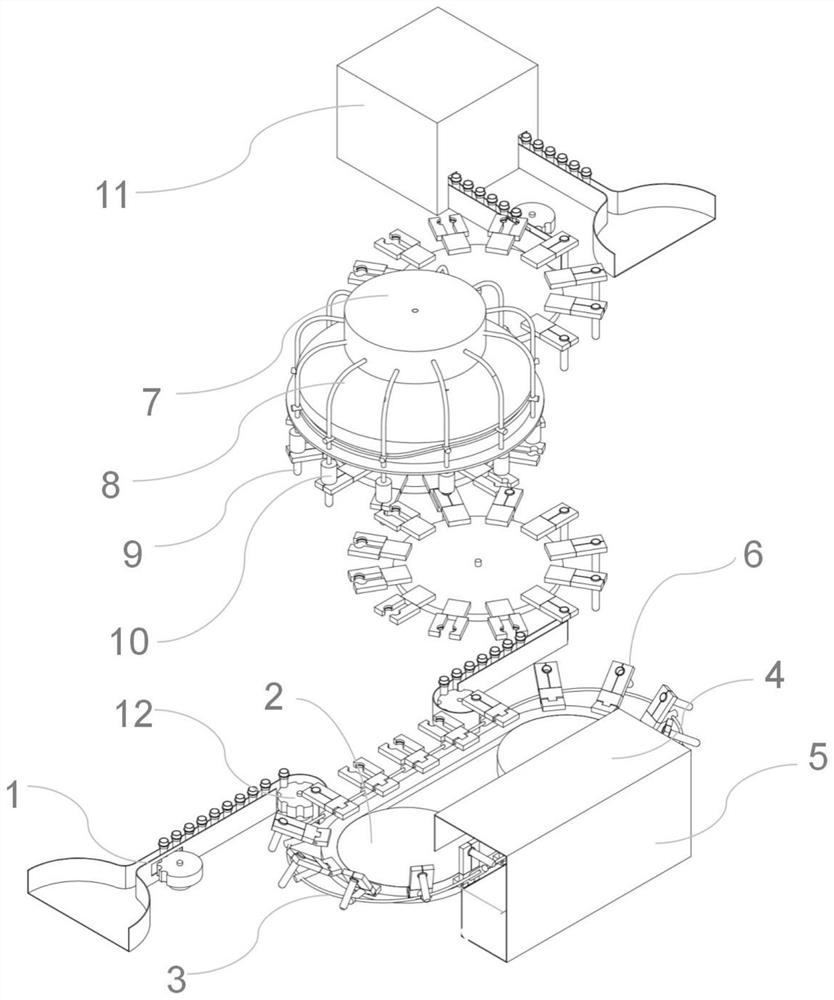

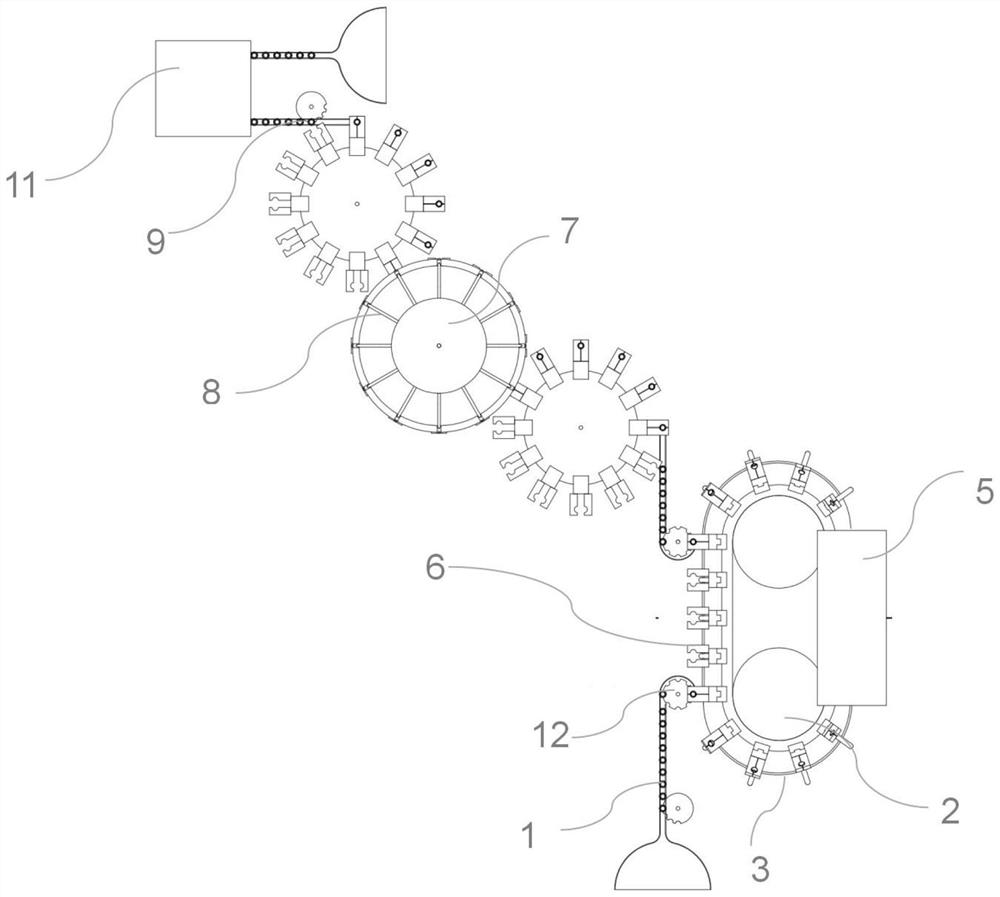

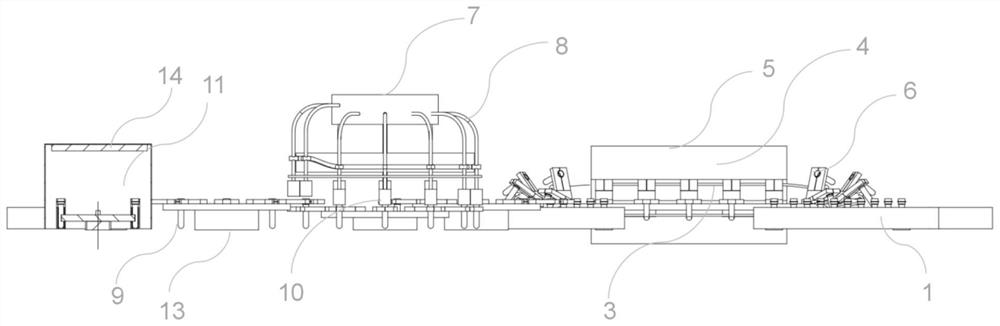

Device for sterilizing PET bottle blanks by coupling ray irradiation with gaseous hydrogen peroxide

The invention discloses a device for sterilizing PET bottle blanks by coupling ray irradiation with gaseous hydrogen peroxide. The device comprises a bottle blank conveying track, a ray irradiation sterilization section, a gaseous hydrogen peroxide sterilization section and a heating section, wherein the bottle blanks sequentially enter the ray irradiation sterilization section, the gaseous hydrogen peroxide sterilization section and the heating section through the bottle blank conveying track to complete comprehensive sterilization, and a ray irradiation pre-sterilization section is used for sterilizing the outsides of the bottle blanks; the gaseous hydrogen peroxide sterilization section is used for sterilizing the necks and the interiors of the bottle blanks; and the heating section is used for accelerating removal of ozone generated by ray irradiation, and activating gaseous hydrogen peroxide attached to the bottle blanks so as to further improve the sterilization effect and accelerate volatilization of the gaseous hydrogen peroxide. According to the device for sterilizing the PET bottle blanks, ray irradiation and the gaseous hydrogen peroxide are coupled to achieve the synergistic effect on the outer surfaces, the interiors and the necks of the bottle blanks, the sterilization efficiency is high, the sterile state of the bottle blanks is guaranteed, physical sterilization energy consumption is reduced, and meanwhile, the use amount of the gaseous hydrogen peroxide is reduced, and the hydrogen peroxide residual risk is reduced.

Owner:CHINA AGRI UNIV

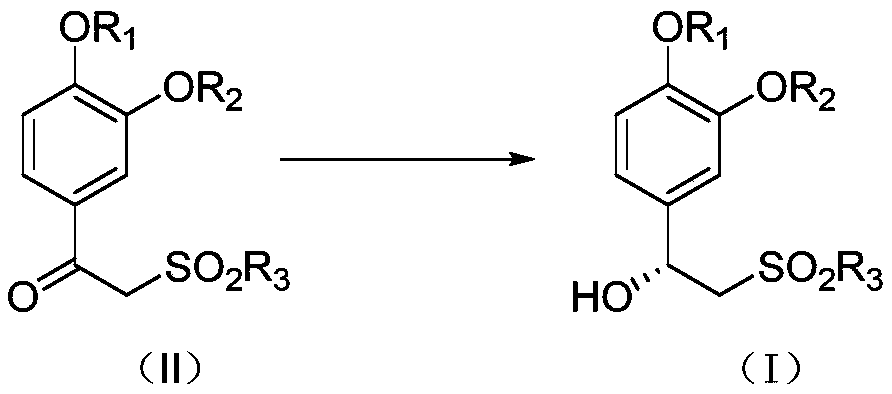

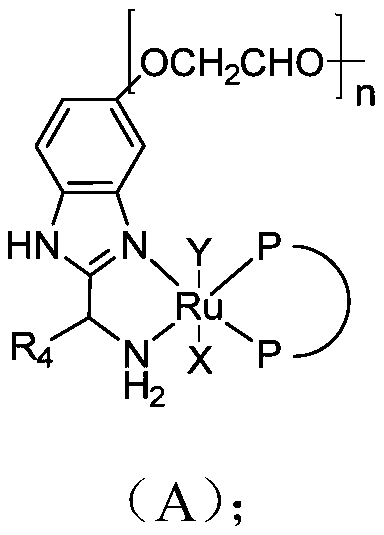

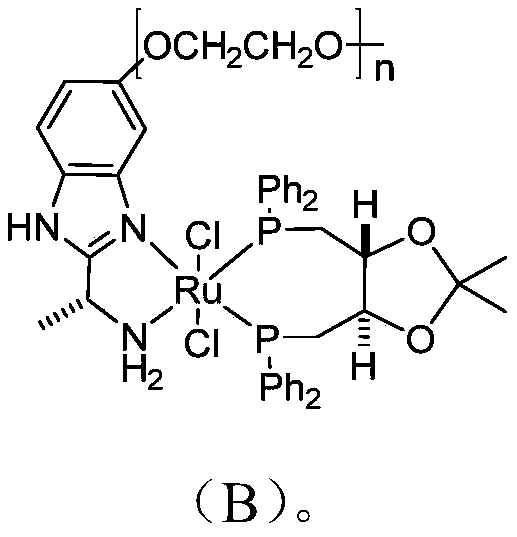

Preparation method of (R)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethanol

ActiveCN111518000AAchieve solid phaseEnhanced interactionOrganic chemistryOrganic compound preparationEthoxidineAryl

The invention relates to a preparation method of (R)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethanol. The preparation method comprises the following steps: providing a compound with a structureshown as a formula (II); carrying out a catalytic hydrogenation reaction on the compound with the structure shown in the formula (II) to prepare a compound shown in a formula (I), wherein a catalystadopted in the catalytic hydrogenation reaction has a structure as shown in a formula (A) which is described in the specification. In the formula (A), X and Y are halogen independently; n ranges from12 to 65; a fragment as described in the specification is a diphosphorus ligand; R1, R2 and R3 are each independently selected from a group consisting of C1-16 alkyl groups, three-to-eight-membered cycloalkyl groups, five-to-ten-membered aryl groups and five-to-ten-membered heteroaryl groups; and R4 is H or a C1-8 alkyl group. The method can effectively reduce heavy metal residues while improvingan asymmetric conversion rate, and lays a foundation for industrial production of apremilast.

Owner:ENANTIOTECH CORP +1

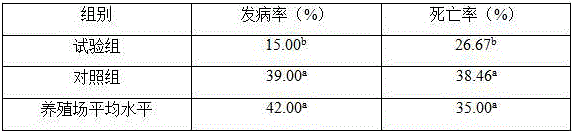

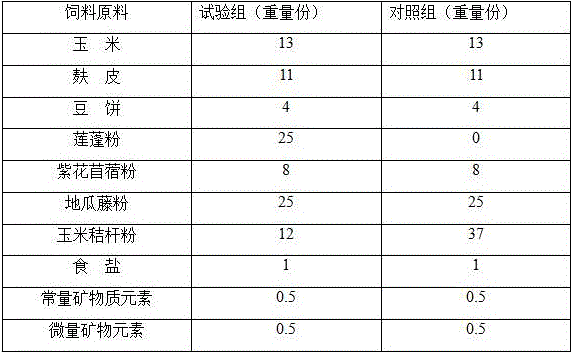

Compound feed for reducing diarrhea rate of goat

InactiveCN106343173APromote healthy growthReduce dosageFood processingAnimal feeding stuffTrace MineralsFodder

The invention relates to a compound feed for reducing diarrhea rate of goat; the compound feed, in the formula, is made from, by weight, 12-15 parts of corn, 10-12 parts of wheat bran, 3-4 parts of soybean cake, 20-30 parts of lotus seedpod powder, 6-8 parts of alfalfa, 20-30 parts of Caulis Fici Tikouae powder, 10-12 parts of corn stalk powder, 0.8-1 part of edible salt, 0.4-0.6 part of constant mineral elements, and 0.4-0.6 part of trace mineral elements. The pellet feed prepared by mixing the lotus seedpod as medicinal feed with other feed materials can control diarrhea in goat significantly.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI +1

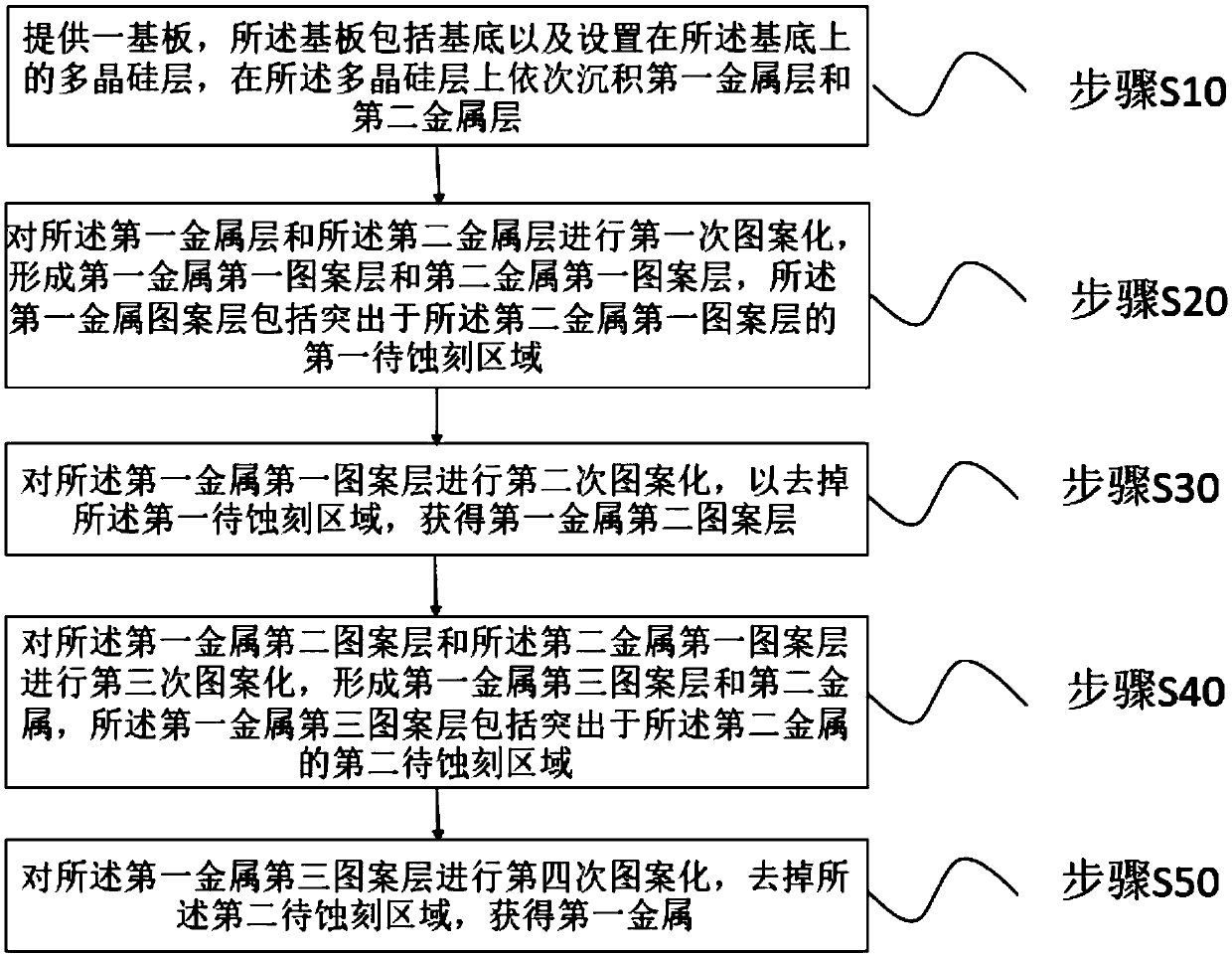

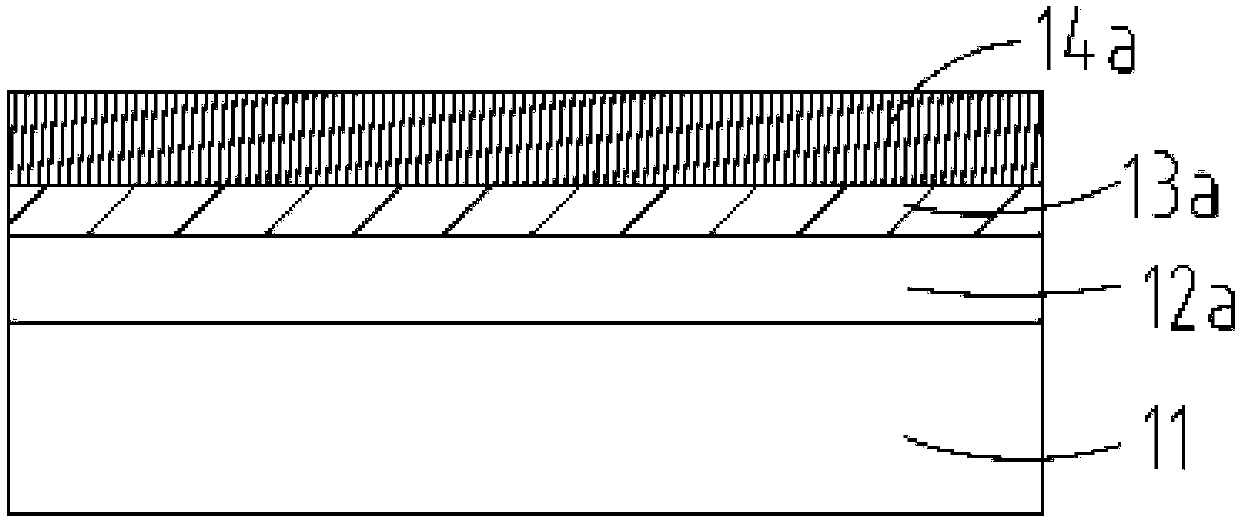

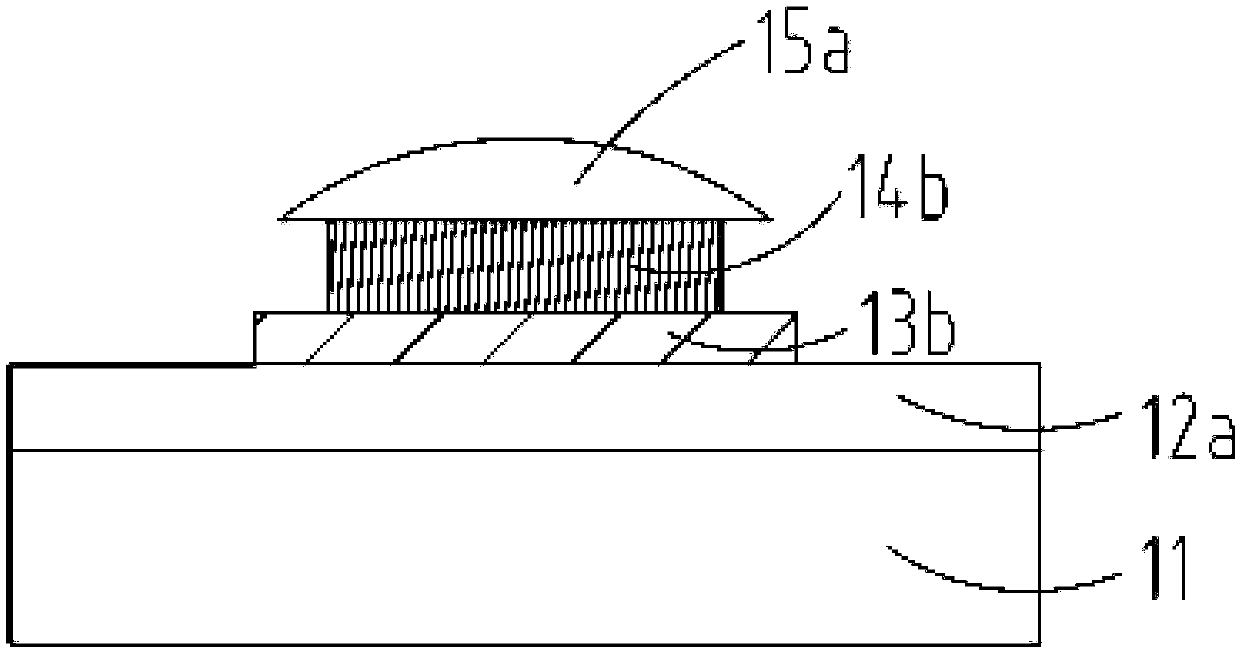

A manufacturing method of an array substrate

ActiveCN109103140AReduce wet etch timeReduce residual riskSolid-state devicesSemiconductor/solid-state device manufacturingThin metalDry etching

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com