Cleaning and regenerating method of titanium crucible

A technology for crucibles and materials, applied in cleaning methods and utensils, chemical instruments and methods, drying solid materials without heating, etc. The effect of cleaning time, stable performance, and low risk of chemical residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

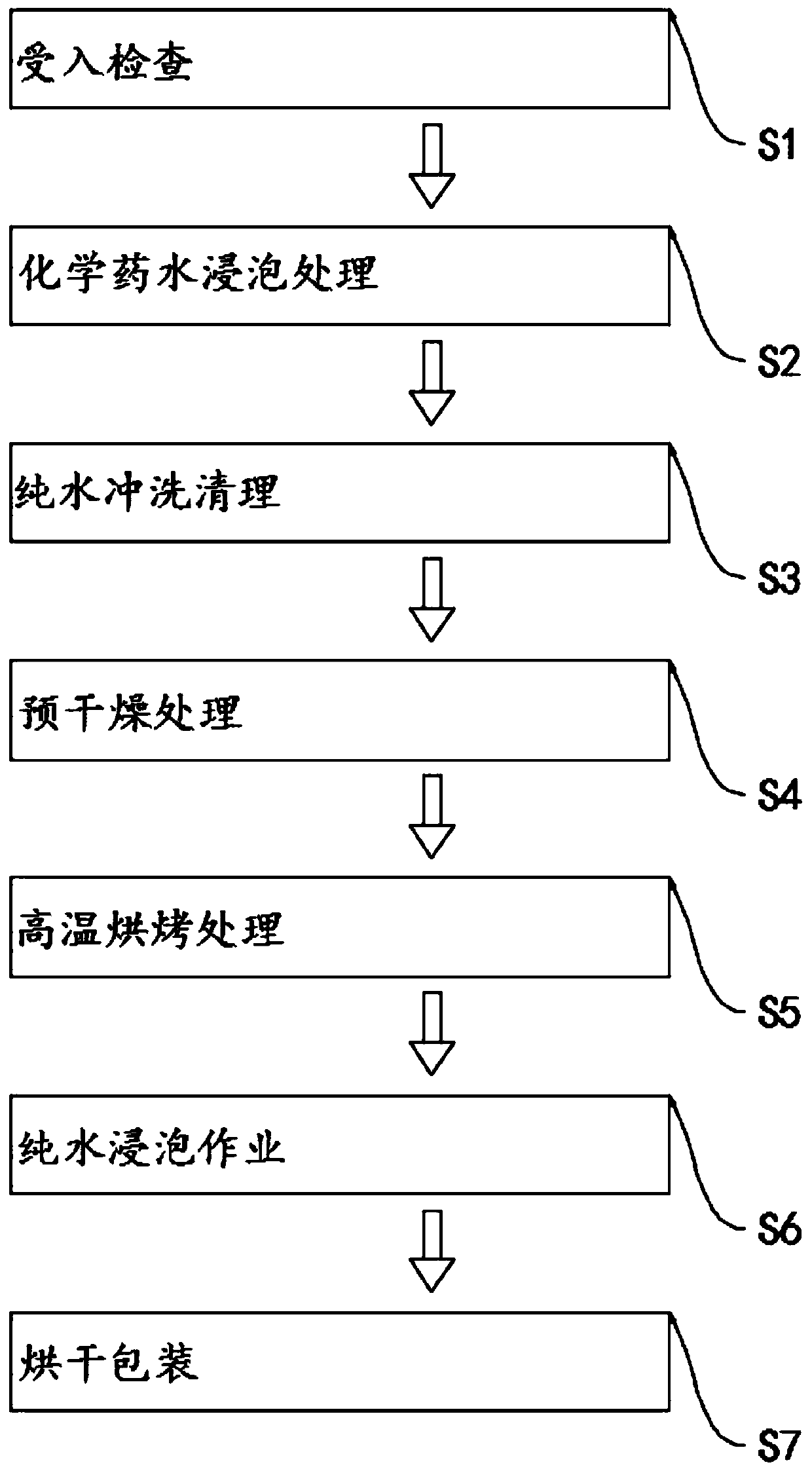

[0043] A method for cleaning and regenerating a titanium material crucible provided in a preferred embodiment of the present invention comprises the following steps:

[0044] S1 Acceptance inspection: ensure that the body of the titanium crucible has no defects, and determine the residual amount of the film layer;

[0045] S2 chemical potion soaking: remove the residual film on the surface, the chemical potion is different according to the film quality inside the crucible, for example: for the organic material inside the crucible use organic solvent ethanol, acetone, etc. as soaking potion, for the metal material inside the crucible use Nitric acid, hydrochloric acid, etc. are used as soaking liquids,

[0046] S3 pure water washing: remove floating ash and impurities on the surface of the crucible;

[0047] S4 Pre-drying: Air gun blows the surface to remove surface moisture. The temperature in the drying box is 100-200°C. The temperature can be 100, 150, and 200°C. The drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com