Air inlet and dust removal device and air delivery device with air inlet and dust removal device

A technology of dust removal device and air intake, which is used in steam flow control, electrode cleaning, electrostatic effect separation, etc., can solve problems such as difficulty and inconvenience, and achieve the effect of avoiding dust spilling, simple cleaning process, and solving the effect of disassembling equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

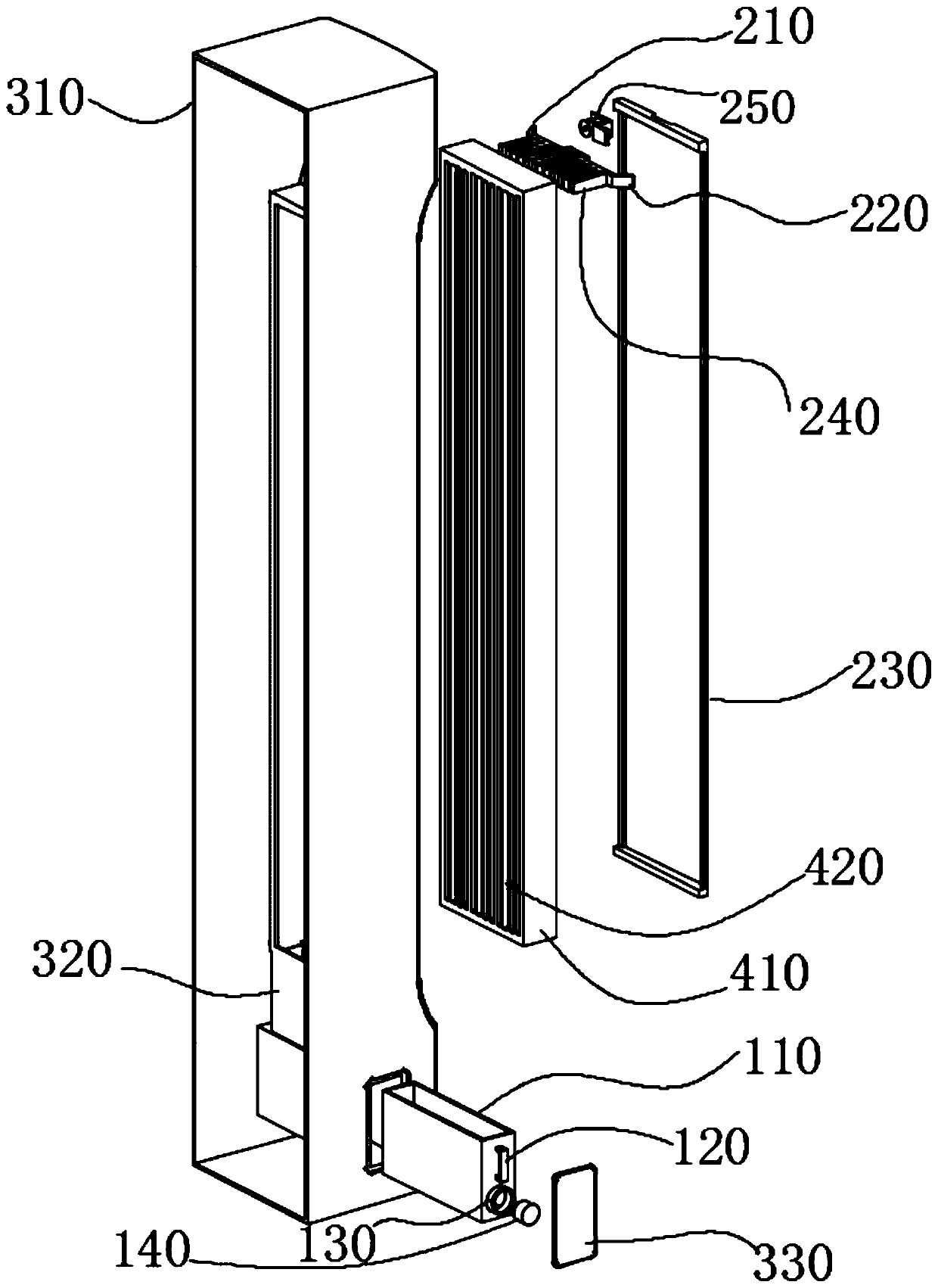

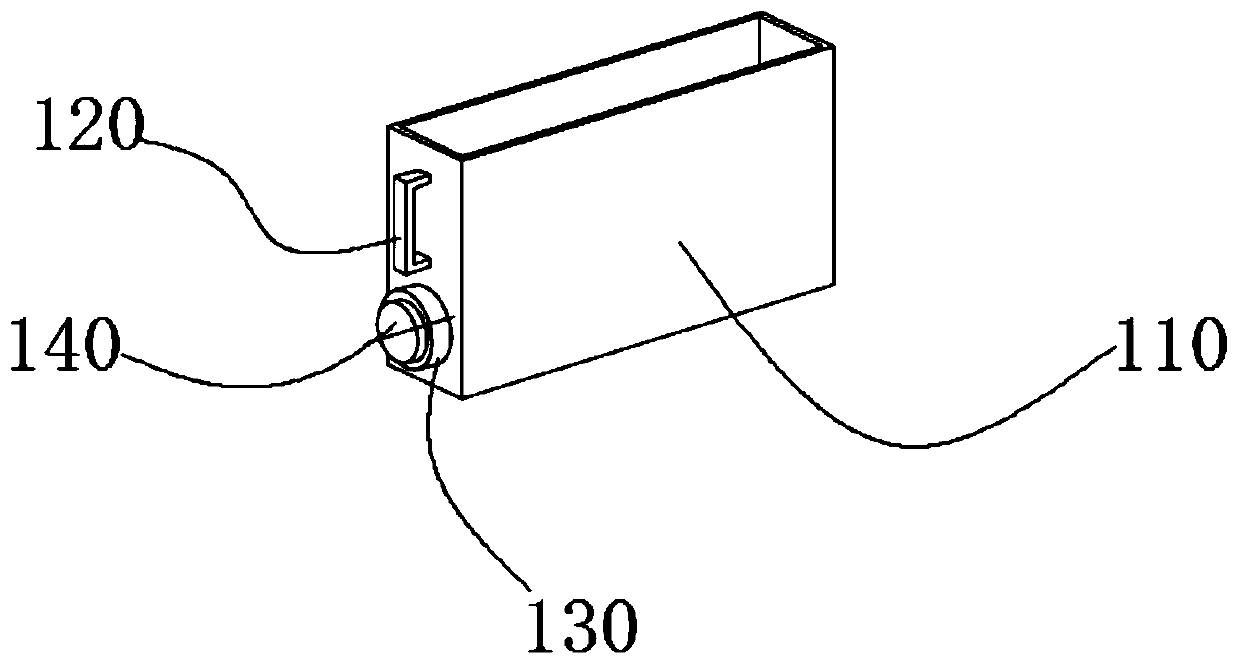

[0057] A kind of air intake dust removal device, such as figure 1 As shown, a housing 310 and an electrostatic precipitator, a cleaning mechanism and a dust collection box located in the housing 310 are provided; the electrostatic precipitator is assembled in the air inlet channel in the housing 310, the cleaning mechanism is assembled in the electrostatic precipitator, and the dust collection The box is arranged under the electrostatic precipitator. When the air flow enters the air inlet channel, the electrostatic dust removal mechanism can absorb the dust in the air flow to its surface, and then the dust adsorbed on the electrostatic dust removal module can be cleaned and dropped into the dust collection box through the cleaning mechanism. The dust box can be taken out directly without disassembly, which eliminates the difficulty of disassembling the device and reduces the burden on users.

[0058] The housing 310 is provided with a dust collection channel 320, and the upper ...

Embodiment 2

[0067] An air inlet dust removal device, other features are the same as in Embodiment 1, the difference is that it is also provided with the following technical features: the electrostatic dust removal mechanism is provided with a frame 410 and multiple sets of grids 420, and multiple sets of grids 420 are assembled on the frame 410 , there are gaps between two adjacent groups of grilles 420 , and the gaps between the grilles 420 and the grilles 420 form the air inlet surface. The frame 410 plays the role of connecting the air inlet channel and providing a fixed position for the grilles 420, and there is a gap between the grilles 420 to ensure that the air flow at the air inlet passes through the electrostatic precipitator.

[0068] It should be noted that the number of grids 420 in this embodiment is not unique, and the number of grids 420 can be increased or decreased according to the size of the frame 410 .

[0069] In this embodiment, multiple sets of grids 420 are arrange...

Embodiment 3

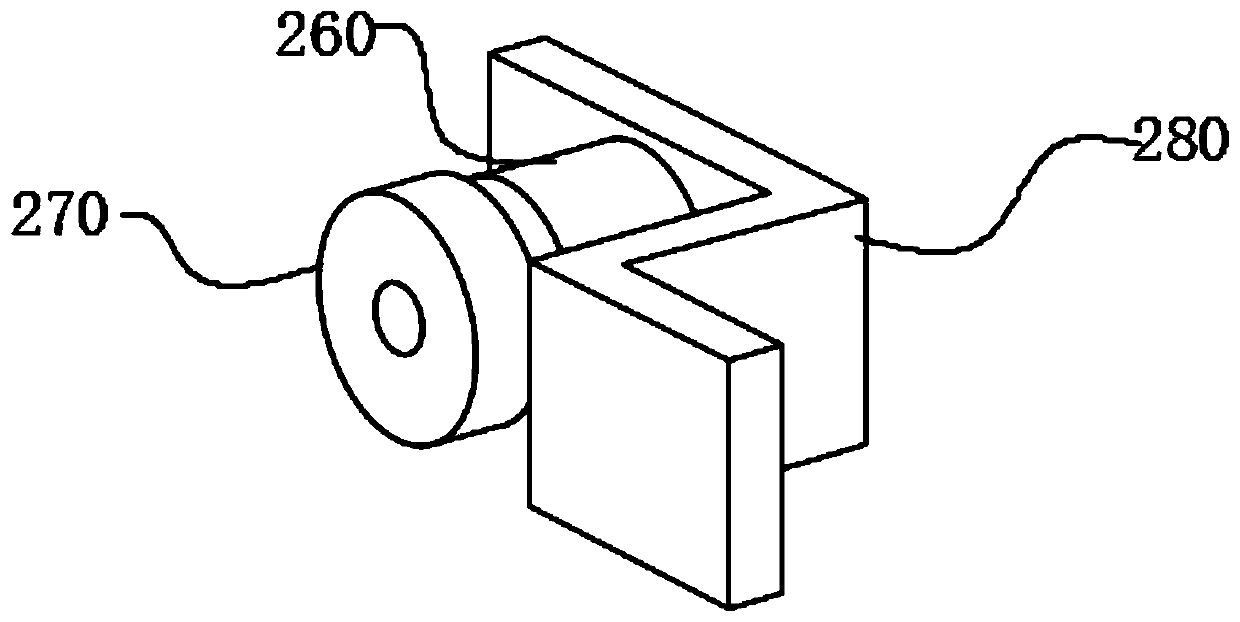

[0074] A kind of air intake and dust removal device, the other features are the same as those of Embodiment 1, the difference is that it also has the following technical features: it is provided with a cleaning mechanism, such as Figure 4 As shown, the cleaning mechanism is provided with a cleaning brush 210, and the cleaning brush 210 is assembled on the electrostatic dust removal mechanism. The cleaning brush 210 can finally brush off the dust on the grid 420 of the electrostatic precipitator mechanism.

[0075] The cleaning brush 210 of this embodiment is provided with a plurality of comb teeth 240 . It should be noted that the number of comb teeth 240 is at least one more than the number of grids 420 of the electrostatic precipitator mechanism.

[0076] In this embodiment, the surface material of the comb teeth 240 can be set to leather, fiber or animal hair. When selecting the material, it is necessary to ensure that the surface of the comb teeth 240 can fully contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com