Liquid filter and cleaning and regeneration method thereof

A liquid filter and filter component technology, applied in chemical instruments and methods, fixed filter element filters, filtration separation, etc., can solve the problems of high labor cost, laborious, bursting tubes, etc., to prevent the deposition of filter residue and save economic costs , The effect of high filter residue deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

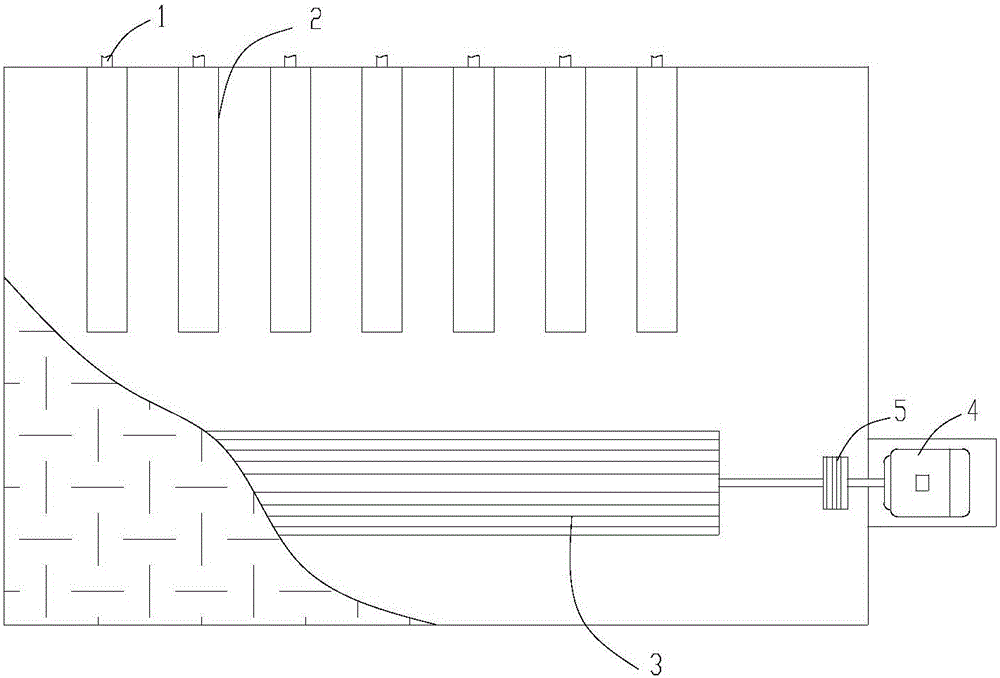

[0021] like figure 1 The liquid filter shown includes a liquid inlet and at least one filter assembly 2, and is also provided with a stirring mechanism 3 corresponding to the filter assembly 2 and connected with a drive mechanism 4. The filter assembly 2 is made of a flexible porous metal membrane Constructed and has a hollow filter element structure with a liquid outlet 1.

[0022] The flexible porous metal membrane is preferably composed of Ag-Au solid solution, Ti-Zr solid solution, Mg-Cd solid solution, Fe-Cr solid solution or Ni-Cu solid solution as the metal porous material of the matrix phase, and its filtration resistance is small, and the filtration accuracy is relatively high. High, large filtration flux, high use intensity, even after repeated cleaning, it can still maintain a good filtration effect. In practical application, the liquid filter of the present invention includes more than two filter assemblies 2 arranged at intervals, and multiple filter assemblies 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com