Water-based coloring layer coating for transfer film and preparation method of water-based coloring layer coating

A technology of coloring layer and transfer film, applied in the direction of fire retardant coatings, coatings, etc., can solve the problems of non-appearance and lack of technical support, and achieve the effect of avoiding pollution, improving the working environment and comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

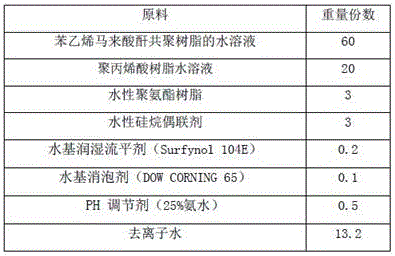

[0043] This embodiment relates to a water-based coloring layer coating for transfer film and its preparation method, especially to a pure water-based coloring layer coating for thermal transfer film (anodized aluminum), the coating adopts the following Table 1 The components and contents are raw materials, and its preparation method is as follows:

[0044] 1) In the No. 1 reactor, turn on the agitator, stir at a speed of 80 rpm, add deionized water in turn, add alkaline reaction auxiliary agent (preferably ammonia water); then add solid styrene maleic anhydride copolymer resin, heat to 45 ~98°C, until all the solid substances are reacted and dissolved to make an aqueous solution of styrene-maleic anhydride copolymer resin, adjust the pH value to 7.5-8.5 with ammonia water, and seal it in a container for later use;

[0045] 2) In the No. 2 reaction kettle, turn on the agitator, stir at a speed of 80 rpm, add deionized water in turn, add alkaline reaction auxiliary agent (prefer...

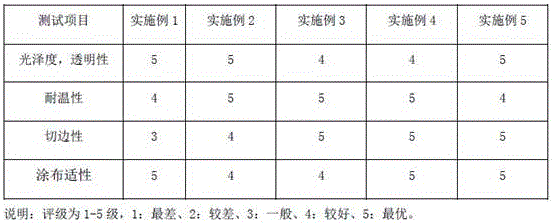

Embodiment 2

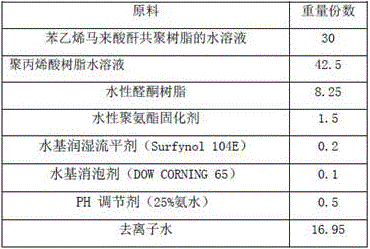

[0053] This embodiment relates to a water-based coloring layer paint for transfer film and its preparation method, especially to a pure water-based coloring layer paint for thermal transfer film (anodized aluminum), the paint uses the following Table 2 The components and contents are raw materials, and its preparation method is the same as in Example 1:.

[0054] Table 2:

[0055]

[0056] Note: Raw material specifications in the table: Styrene maleic anhydride copolymer resin: maleic anhydride content: 26wt.%, Tg value: 160°C, acid value: 300mgKOH / g, molecular weight: 80000g / mol, solid content NV : 10%; polyacrylic acid resin: acid value: 230 mgKOH / g, molecular weight: 6500 g / mol, Tg value: 107 ℃), solid content NV: 30%.

Embodiment 3

[0058] This embodiment relates to a water-based coloring layer coating for transfer film and its preparation method, especially to a pure water-based coloring layer coating for thermal transfer film (anodized aluminum), the coating adopts the following table 3 The components and contents are raw materials, and its preparation method is the same as in Example 1:.

[0059] table 3:

[0060]

[0061] Note: Raw material specifications in the table: Styrene maleic anhydride copolymer resin: maleic anhydride content: 26wt.%, Tg value: 160°C, acid value: 320mgKOH / g, molecular weight: 120000g / mol, solid content NV : 13%; polyacrylic acid resin: acid value: 218mgKOH / g, molecular weight: 11500 g / mol, Tg value: 105 ℃), solid content NV: 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com