Preparation method of (R)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethanol

A technology of alkoxyphenyl and alkylsulfonyl, applied in the field of preparation of -1--2-ethanol), which can solve problems such as failure to meet drug quality standards and multiple metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

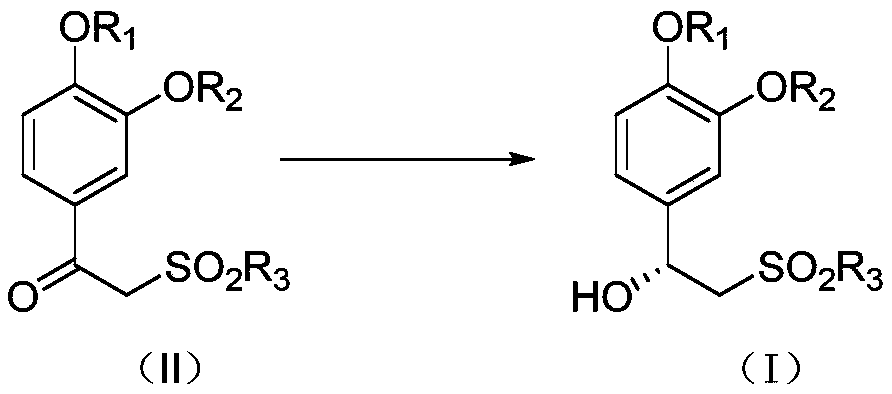

[0047] The preparation method of (R)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethanol) according to one embodiment of the present invention comprises the following steps:

[0048] S101: providing a compound of the structure shown in formula (II);

[0049]

[0050] Among them, R 1 , R 2 and R 3 each independently for C 1-16 Alkyl, 3-8 membered cycloalkyl, 5-6 membered aryl or 5-6 membered heteroaryl; further, R 1 , R 2 and R 3 each independently for C 1-6 Alkyl, 3-6 membered cycloalkyl, 6 membered aryl or 6 membered heteroaryl; further, R 1 , R 2 and R 3 each independently for C 1-4 Alkyl or phenyl.

[0051] The structural compound represented by formula (II) can be obtained by using commercially available raw materials, or can be synthesized by existing methods, and is not particularly limited here. For example: Synthesize using the following method:

[0052]

[0053] Remove the ketone carbonyl α-position active wave hydrogen of the compound shown in t...

Embodiment 1

[0103]

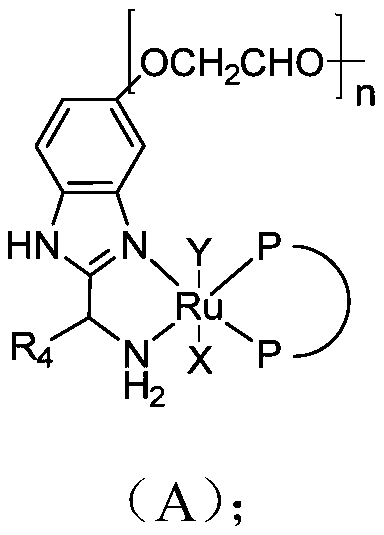

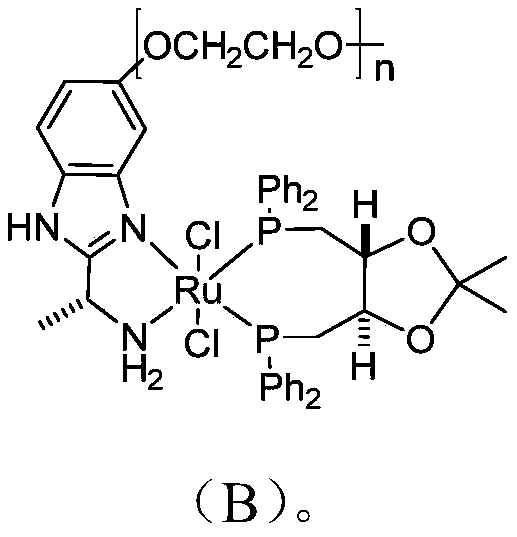

[0104] In a 5L autoclave, under an argon atmosphere, add 100g of compound 1 from the feeding port, then add 1.5L of toluene to fully dissolve the raw material, stir fully and continuously pass in argon gas to degas by bubbling, and continue bubbling for 1h. Degassing is complete. Add 0.2g catalyst to the feeding port Wherein n is 12), and the feeding port is closed rapidly. Replace the argon with hydrogen, slowly introduce hydrogen to 3.0Mpa, and close the inflation valve. Rapidly stirred reactions were carried out at 25-40°C. When the pressure drops to remain constant, the reaction is considered to stop. Sampling was sent for liquid phase analysis to confirm the conversion rate. After the reaction, the system was filtered with suction. The catalyst was removed, and the filtrate was concentrated under reduced pressure to obtain an off-white solid, which was tested for residual heavy metals, chiral purity, catalyst recovery, and absolute configuration.

Embodiment 2

[0106]

[0107] In a 5L autoclave, under an argon atmosphere, add 100g of compound 1 from the feeding port, then add 1.5L of toluene to fully dissolve the raw material, stir fully and continuously pass in argon gas to degas by bubbling, and continue bubbling for 1h. Degassing is complete. Add 0.2g catalyst ( Wherein n is 16), and the feeding port is closed rapidly. Replace the argon with hydrogen, slowly introduce hydrogen to 3.0Mpa, and close the inflation valve. Rapidly stirred reactions were carried out at 25-40°C. When the pressure drops to remain constant, the reaction is considered to stop. Sampling was sent for liquid phase analysis to confirm the conversion rate. After the reaction, the system was filtered with suction. The catalyst was removed, and the filtrate was concentrated under reduced pressure to obtain an off-white solid, which was tested for residual heavy metals, chiral purity, catalyst recovery, and absolute configuration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com