Nitrogen-doped carbon-based metal monoatomic catalyst as well as preparation method and application thereof

A nitrogen-doped carbon, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Avoid physical adsorption, improve catalytic activity, and increase the effect of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Step 1. Dissolve 1.0g (0.01mol) of calcium carbonate and 0.0483g (0.000179mol) of ferric chloride hexahydrate in 3ml of deionized water, let stand for 25min, and dry at 110°C for 9h to obtain FeCl 3 @CaCO 3 Precursor;

[0056] Step two, take 1.0g FeCl 3 @CaCO 3 Precursor, 2.7g 1,2-propylenediamine and 6.0g carbon tetrachloride were placed in a flask, ultrasonically dispersed for 5-10 minutes, refluxed at 70°C for 8h, and dried at 120°C for 10h;

[0057] Step 3, place the dried solid in a tube furnace, vacuumize, blow nitrogen, and carbonize at 600°C for 5 hours, with a heating rate of 5°C / min, to obtain a carbonized product;

[0058] Step 4: Wash the carbonized product with 1 mol / L HCl solution, wash with deionized water several times, and dry at 110°C for 8 hours to obtain the nitrogen-doped carbon-based metal single-atom catalyst (Fe-N-C catalyst).

[0059] The catalytic performance of the catalyst was evaluated by Fenton’s method of oxidation degradation of malac...

Embodiment 2

[0066] A preparation method of nitrogen-doped carbon-based metal single-atom catalyst:

[0067] Step 1. Dissolve 0.5g (0.005mol) of calcium carbonate and 0.049g (0.00018mol) of ferric chloride hexahydrate in 3ml of deionized water, let stand for 20min, and dry at 110°C for 9h to obtain FeCl 3 @CaCO 3 Precursor;

[0068] Step two, take 0.5g FeCl 3 @CaCO 3 Precursor, 2.5g 1,2-propanediamine and 5.0g carbon tetrachloride were placed in a flask, ultrasonically dispersed for 5-10 minutes, refluxed at 70°C for 8h, and dried at 120°C for 9h;

[0069] Step 3. Put the dried solid in a tube furnace, vacuumize, blow nitrogen, and carbonize at 400°C for 6 hours, with a heating rate of 3°C / min, to obtain a carbonized product;

[0070] Step 4: Wash the carbonized product with 2 mol / L HCl solution, wash with deionized water multiple times, and dry at 110° C. for 9 hours to obtain the nitrogen-doped carbon-based metal single-atom catalyst (Fe—N—C catalyst).

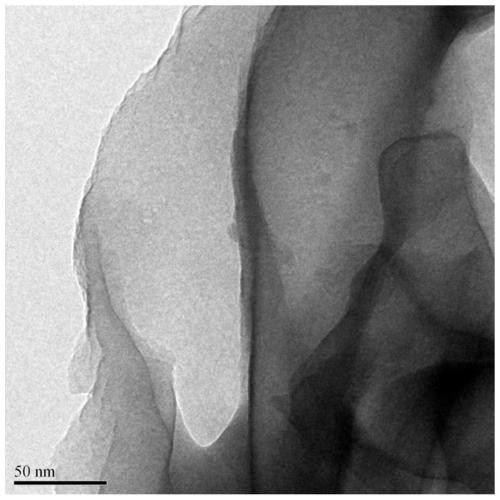

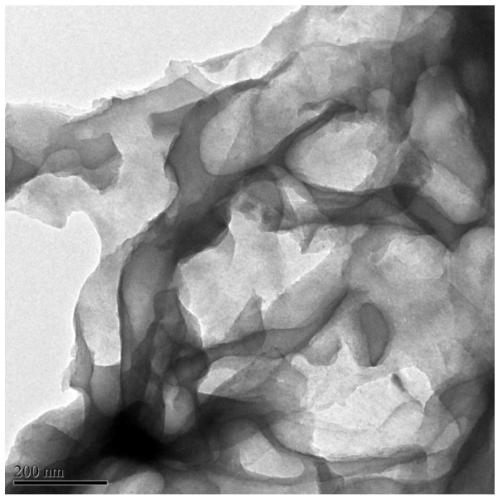

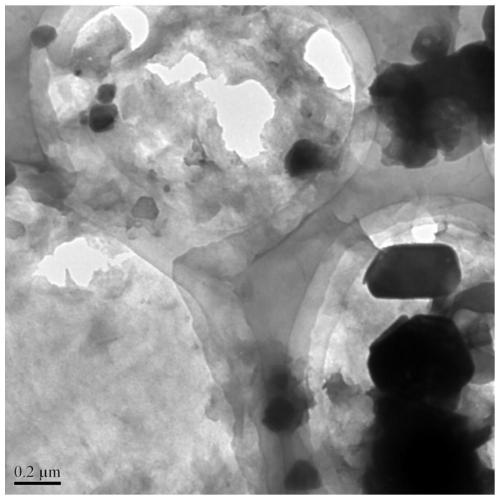

[0071] The transmission elec...

Embodiment 3

[0074] A preparation method of nitrogen-doped carbon-based metal single-atom catalyst:

[0075] Step 1. Dissolve 1.0g (0.01mol) of calcium carbonate and 0.049g (0.000103mol) of ferric chloride hexahydrate in 3ml of deionized water, let stand for 30min, and dry at 100°C for 10h to obtain FeCl 3 @CaCO 3 Precursor;

[0076] Step two, take 1.0g FeCl 3 @CaCO 3 Precursor, 1.7g 1,2-propylenediamine and 5.2g carbon tetrachloride were placed in a flask, ultrasonically dispersed for 5-10 minutes, refluxed at 70°C for 8h, and dried at 120°C for 8h;

[0077] Step 3, put the dried solid in a tube furnace, vacuumize, blow nitrogen, and carbonize at 800°C for 4 hours, with a heating rate of 10°C / min, to obtain a carbonized product;

[0078] Step 4: Wash the carbonized product with 3 mol / L HCl solution, wash with deionized water several times, and dry at 110° C. for 8 hours to obtain the nitrogen-doped carbon-based metal single-atom catalyst (Fe—N—C catalyst).

[0079] The transmission e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com