Sterilizing mask bag capable of being repeatedly opened and sealed

A mask and composite film technology, applied in bags, sacks, closure devices, etc., can solve the problems of excessive ethylene oxide residue, pollution of remaining masks, and inability to re-seal, so as to reduce the risk of ethylene oxide residue and reduce packaging. The effect of cost and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

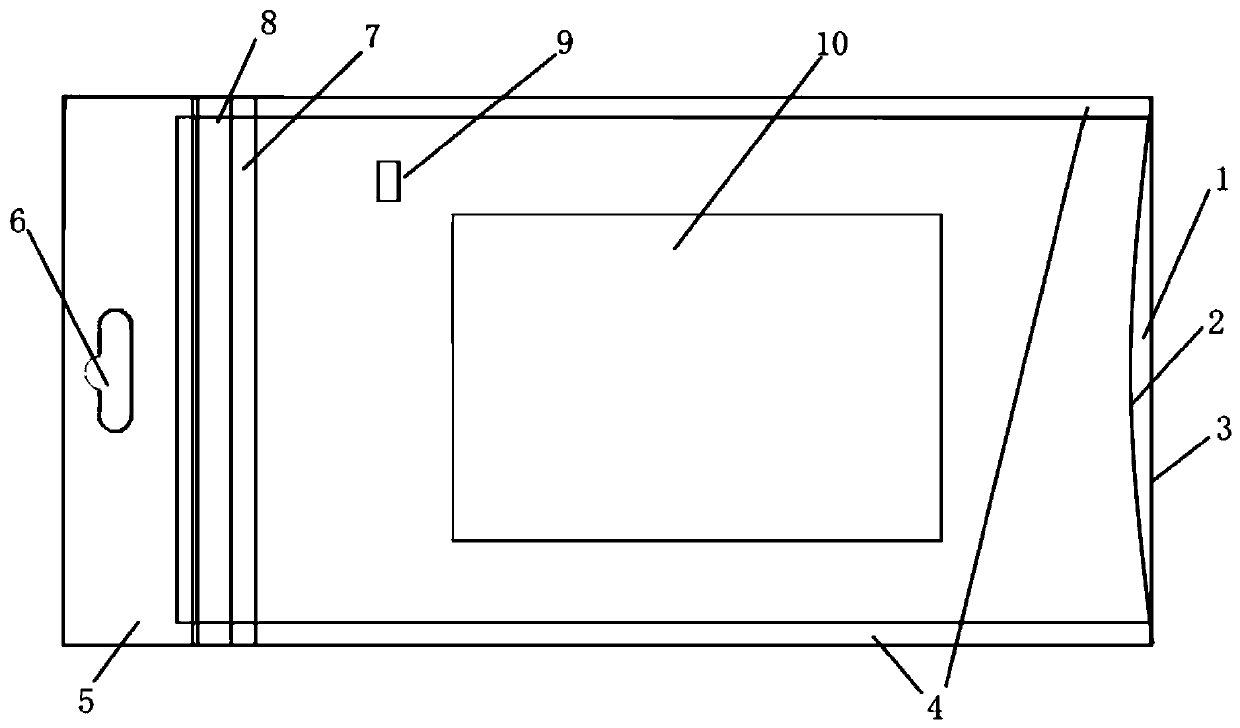

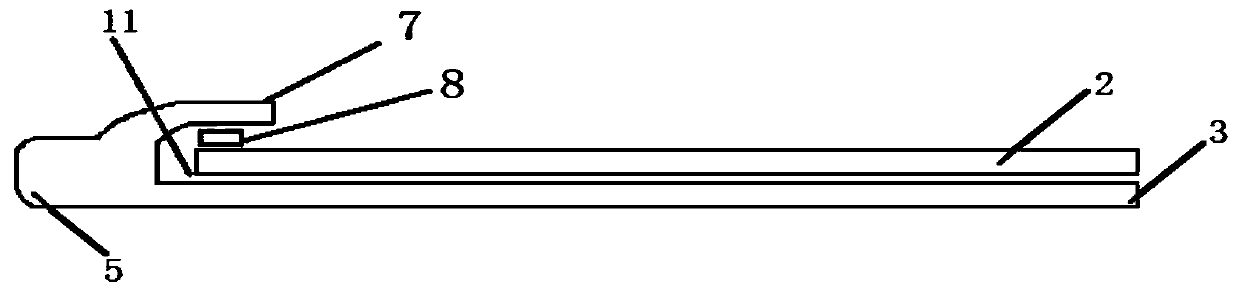

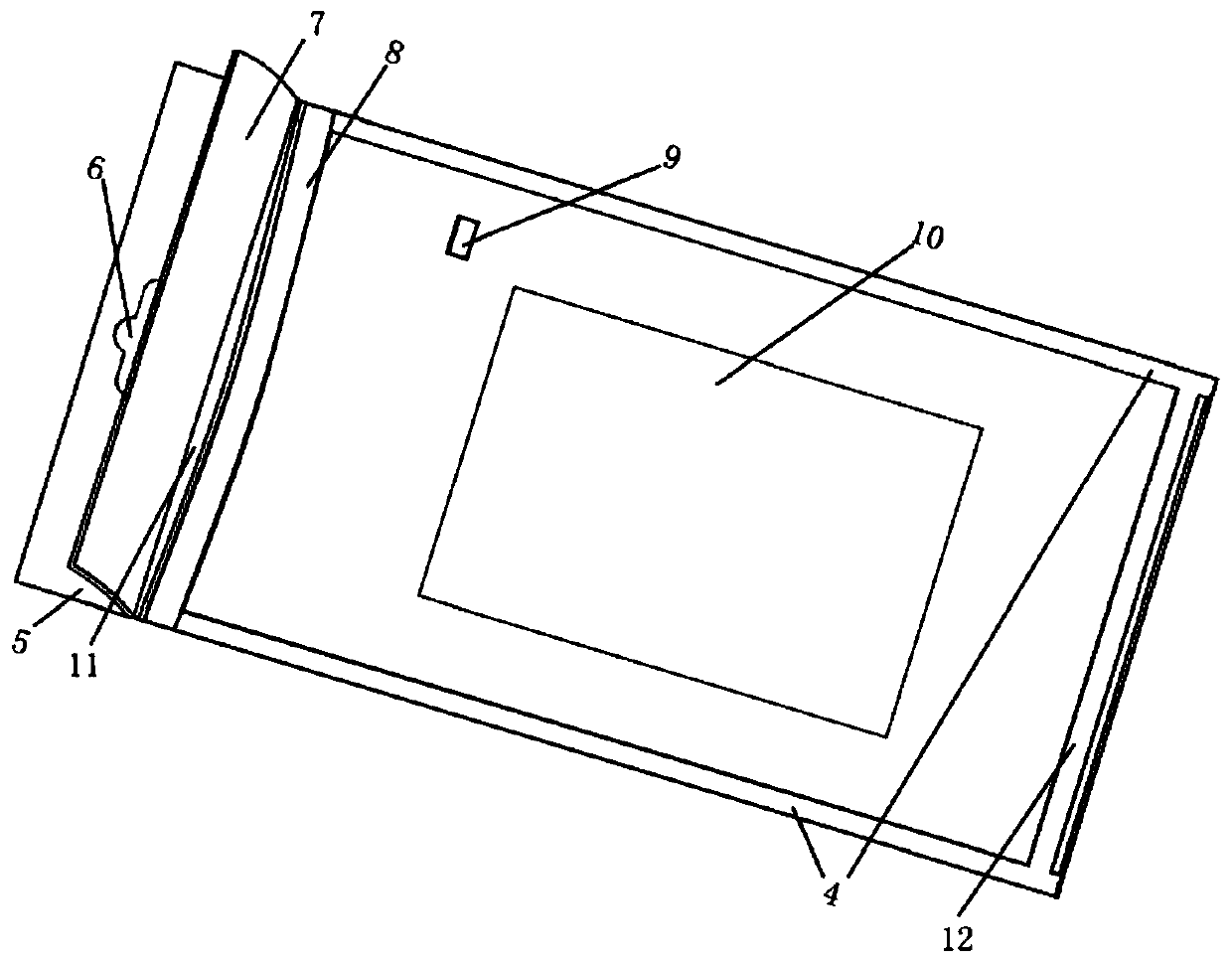

[0031] combine Figure 1 ~ Figure 3 As shown, it is a re-openable and sealed sterilized mask bag provided according to a preferred embodiment of the present invention. The sterilized mask bag is sealed and ironed by medical dialysis paper 2 and plastic composite film 3. Plastic composite film 3 The three sides of the medical dialysis paper 2 are aligned with the three sides of the medical dialysis paper 2, wherein the two ends along the length direction are connected by sealing and ironing to form an ironing seam 4, and one end along the width direction is not sealed and ironed temporarily to form a mask bag pocket 1, after being loaded into the mask Then seal and connect, at the other end along the width direction, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com