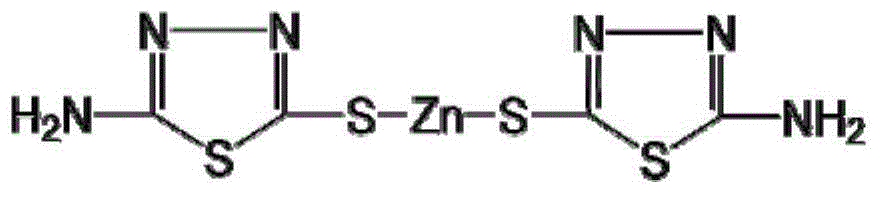

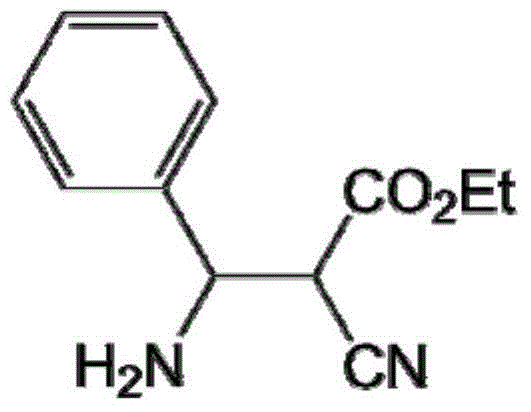

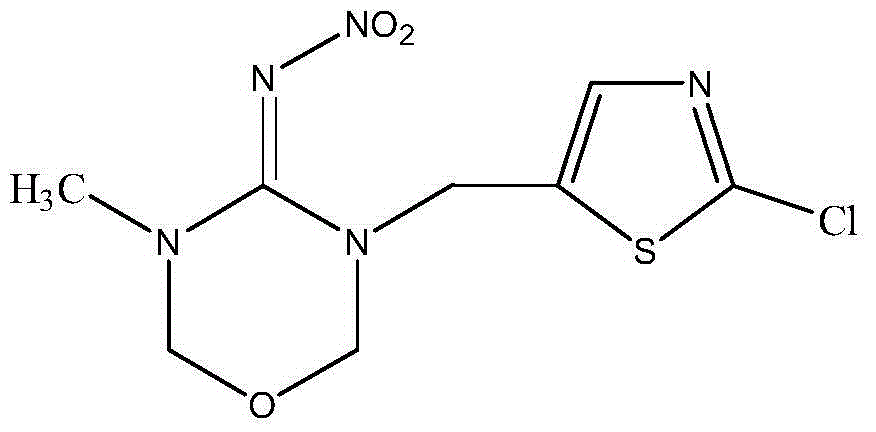

Agricultural composition containing zinc thiazole and phenamacril, and preparation and application thereof

A technology of cyclostrobin and thiazole-containing zinc, which is applied in the field of pesticides, can solve the problems of easy resistance, poor effect, and single purpose, and achieve the effects of promoting root growth, expanding the bactericidal spectrum, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1: preparation of suspension

[0095]40% active compound (20.0% thiazole zinc and 20.0% cyclostrobin composition), fatty alcohol polyoxyethylene ether 2.0%, alkyl naphthalene sulfonate 3.0%, sodium methylene dinaphthalene sulfonate 1.0%, Xanthan gum 0.05%, magnesium aluminum silicate 0.6%, sodium starch octenyl succinate 2.3%, glycerin 2.0%, phenyl salicylate 0.4%, silicone defoamer 0.1%, deionized water to make up to 100%, put it into a high-shear homogeneous emulsifier and shear at high speed for 20 minutes, then transfer it to a sand mill, and circulate sand mill for 1-3 times to obtain a suspension containing 40% active compound.

Embodiment 2

[0096] Embodiment 2: preparation of microcapsule suspension

[0097] Zinc thiazole 10.0%, cyprostrobin 15.0%, alkyl naphthalene sulfonate 2.0%, acyl glutamate 1.0%, silicone defoamer 0.1%, polyphenyl polymethylene polyisocyanate PAPI 3% Mix well with 2% diphenylmethane diisocyanate MDI, 10% aqueous solution of gum arabic (5%), and 40.46% deionized water, and then put it into a sand mill for sanding until D 90 The particle size is 3-5 microns. Start stirring (maintain 700 rpm), then raise the temperature of the sand-milled suspension to 60°C, and slowly add 0.04% triethanolamine at the same time to maintain a stable solidification temperature of the capsule wall material for 8 hours, then add fatty alcohol polyoxyethylene ether Sulfate 1.0%, sodium methylnaphthalenesulfonate formaldehyde condensate 1.0%, urea 2.0%, glycerol 2.0%, aluminum magnesium silicate (2%) aqueous solution 10%, appropriate amount of dilute hydrochloric acid aqueous solution to adjust the pH value to abou...

Embodiment 3

[0098] Embodiment 3: preparation of water dispersible granules

[0099] 60% active compound (20.0% thiazole zinc, 25.0% cyprostrobin and 15.0% thiamethoxam combination), lignosulfonate 3.0%, naphthalene sulfonate 3.0%, ammonium sulfate 15.0%, xanthan gum 1.0 %, 1.0% talcum powder, and 17.0% kaolin are fully mixed, and then crushed by airflow and granulated to obtain water-dispersible granules. The water dispersible granules contain 60% active compound, and the particle size of the product is 80-120 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com