Ocean antifouling paint and preparation method thereof

A marine antifouling and coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of expensive raw materials, complex production technology, single bactericidal and antibacterial effects, etc., to reduce drug resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

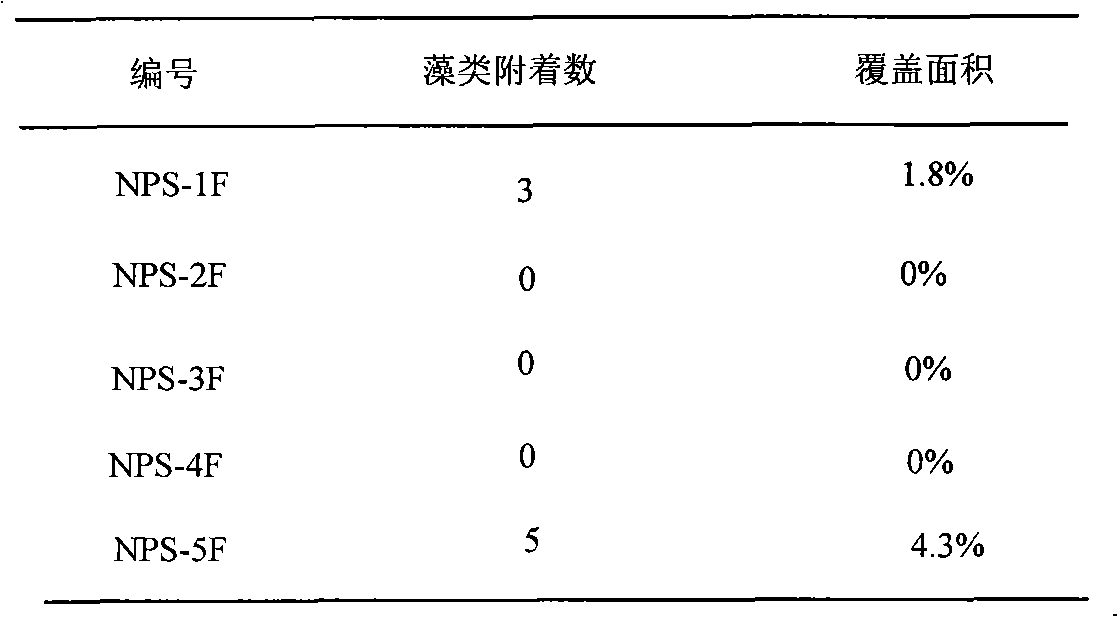

Examples

Embodiment 1

[0035] The preparation of embodiment 1 marine antifouling coating NPS-1F

[0036] Step 1, preparation of tertiary amine type polyacrylate NP-1

[0037] Weigh 20 grams of 2-(N,N-dimethylamino)ethyl methacrylate, 20 grams of methyl methacrylate, 40 grams of butyl methacrylate, 20 grams of ethylene glycol dimethacrylate, and 80 grams of toluene. gram, 80 grams of butyl acetate and 3.0 grams of azobisisobutyronitrile, put them into a polymerization reactor, fill with nitrogen and remove oxygen for 10 minutes, and stir and react at a temperature of 80 to 85°C for 8 hours to prepare tertiary amine polyacrylate NP -1 viscous transparent solution 259 g. Step 2, preparation of salicylaldehyde and quaternary ammonium salt modified polyacrylate NPS-1

[0038] Weigh 32 grams of 5-chloromethyl salicylaldehyde and dissolve it in 30 grams of ethyl acetate, add 259 grams of tertiary amine polyacrylate NP-1 viscous transparent solution prepared in step 1, and stir at room temperature for 20 ...

Embodiment 2

[0041] The preparation of embodiment 2 marine antifouling coating NPS-2F

[0042] According to the method and operation steps of Example 1, the methyl methacrylate in Step 1 of Example 1 was replaced with hexafluorobutyl methacrylate to prepare NPS-2F marine antifouling paint.

Embodiment 3

[0043] The preparation of embodiment 3 marine antifouling coating NPS-3F

[0044] According to the method and operating steps of Example 1, the 2-(N, N-dimethylamino) ethyl methacrylate in the step of Example 1 is replaced with 2-(morpholinyl) ethyl methacrylate, methyl The methyl acrylate was replaced by hexafluorobutyl methacrylate to obtain the NPS-3F marine antifouling coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com